WhooooEEee!!! What a day!!

So, after some inspiration from our hero Pile here, and a good night's rest....

I went after the top end with a fresh outlook.

Before, I was going at it like it was just a 'slap together'.

And, up until now, it kind of was.

Until I got called out...

First thing I did was get the shop area cleaned up, and the board out.

A couple of the wrist pins were tight.

It was driving me nuts all of yesterday.

I think they got burred up at the snap ring groove, maybe?

Was using the MAPP gas torch like in the old V8 days,

Heating up the piston to make the pin slide easier,

But,

Man!

It was cooling off, and giving me fits - all seizing in the piston.

So finally, fuggit, I just reamed it with some Scotch-Brite.

Much better.

Dag, that was driving me nuts!!!

If it wears out sooner, I still say it was worth it.

TOO many times on and off and on and off and on to have this poop going on!

Let's get his whole thing organized proper like.

TDC got marked 180 out, each side.

And every part got labeled big.

Every hole, case, jugs, pistons...

Remember, I'm easily confused.

I'm a gonna chase down exactly where the wonky numbers are.

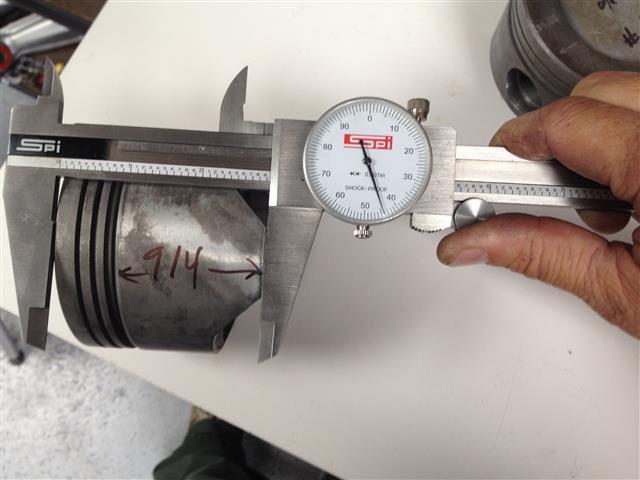

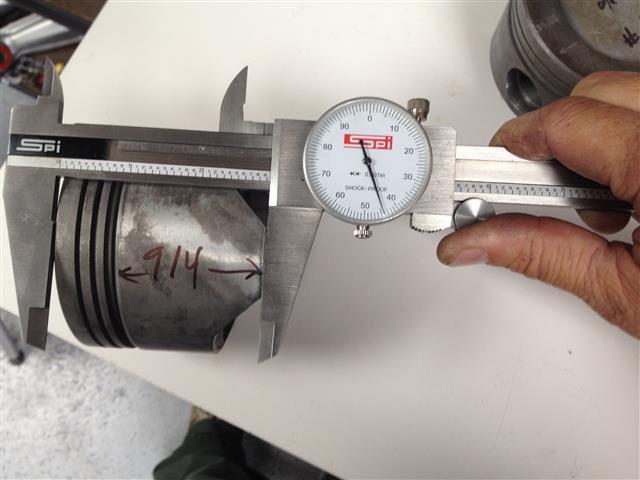

Measured each jug as best I can with a caliper.

Made sure the deck and cylinders don't have any nonsense;

This lays flat right here.

The deck measurement finally started making sense.

My TDC measurement/mark from yesterday was off(!)

GIGO...

Got them all to measure right around .005",

And labeled some more.

So, it was time to take off the old wet/dry 400 from the surface plate...

Figuring out how much to take off of each piston;

Man, there was a LOT of variation in these pistons.

Had to label them all separately with my target number.

Doing for .030 off here. That plus the .005 we already have.

Target number written on the side. Both sides. They were different.

Need to keep things square.

Remember, I'm easily confused...

So, Pile said 50 strokes with some 220.

I figured some 180 would speed the process, especially flooded with solvent....

50 Strokes - Yeah, right!

Good thing I don't listen to what people tell me on the internet!

Humping this thing for several hundred strokes got me like .003...

Now, I'm fat and need some exercise, don't get me wrong, but,

It would take all day to take off .030 by hand....

Time to break out my Ghetto Bench-Mount Belt-Sander.

(Patent Pending)

Don't try this at home kids...

Now we're talking...

Get it within a couple thou on the old 80-grit belt,

And by the time it cleans up on the 180 wet/dry,

There's your number...

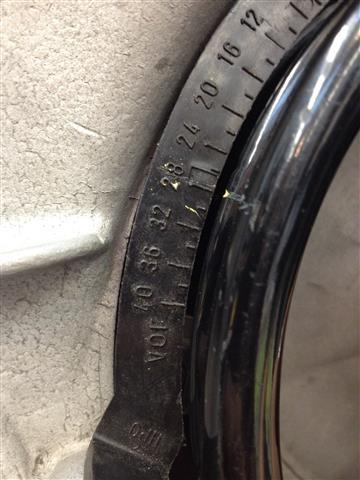

I even walked up to my perfect .035 on every hole.

You can creep up (very very slowly

) on your number with the wet/dry.

Taking the .035 feeler blade off, the mounting hole has a burr on it.

You can use it get a feel, and then some, as you lay it flat, and cruise it around measuring at different spots.

Nutted all four of them....

Damn, I feel cool right now...

Lo and behold, we lost three full CCs by taking .030 off the piston top.

The man is a genius...

My total chamber volume got dropped from 69 to 66 CCs.

Bringing my Compression Ratio up to 7.8.

Pile, I love you, man.... *sniff*

Afterwards, I broke out the die-grinder, ATF, safety gear, and made a big tank of air.

Only to find out some wrist-pin juggling brought me right in line!

Sometimes you get lucky(!)

So, a big cleanup session, and assembly.

I use RTV.

There, I said it.

On a forum. On the Internet.

I don't care what anybody says. Other poop leaks sometimes at cylinder bases.

Proper use of RTV has may facets;

Not the least of which is making sure little dried up balls of it under the cap don't find their way into your project.

Making sure the sharp edge of the snap-rings face out...

Don't let them pushrod tube O-rings pinch.

518 under head washers.

Since the gods smiled on me today,

Couldn't resist taking it this next step, and lapped the jugs to the heads.

Long Block!

A couple of type-4-Isms.

Big Cheese-head screw on top of #3 for some reason...

Smaller small cheese-head under head/cylinder tin for some other reason.

God only knows what those reasons are... Keep us hunting for screws I guess...

Twelve-degree angle of distributor drive - per the Bentley Bible.

Quick-n-dirty cam degree checking.

The "split overlap method".

Making sure that during overlap, (360 degrees from TDC near when plug fires), that both valves are open the same amount at TDC.

You can see my TDC mark on the flywheel, and the level is the same er, level, as the head.

If my marks are correct, and the pushrods are the same length (checked), the cam is 'straight up' as it's supposed to be.

(at least in this case (sorry, pun...

) it's supposed to be run straight up.)

Anyhow,

Mom let me work late into the night tonight,

And now I'm even dressing this motor up a bit!

I have a project going restoring some 72-74 heater boxes (see TOS Type 3 forum for details),

And once those get done, the plan is to run it in on the test-stand for a cam break in.

Just need some linkage arms for my DCNFs here....

*hint* *hint*....

Until next time...

Thanks for keeping me on it, Pile!