Thanks Clatter! I feel like I've cleaned cleaned and more cleaned! I would like to add a tip for anyone who might not know: I wanted to make sure the oil galleys were clear of metal debris, so I took both case halves outside and used a garden hose to flush them out. Sure enough, there were several pieces of metal chips/flakes that were large enough to make me glad for flushing themClatter wrote: ↑Mon Aug 14, 2017 1:11 pm MMmmmMMMmm, That's some nice looking stuff all clean like that.

Love them lifter bore sleeves..

Did you ever have your crank/flywheel/pressure plate/fan spin-balanced as an assembly?

That's worth doing for sure, when you have everything apart like this..

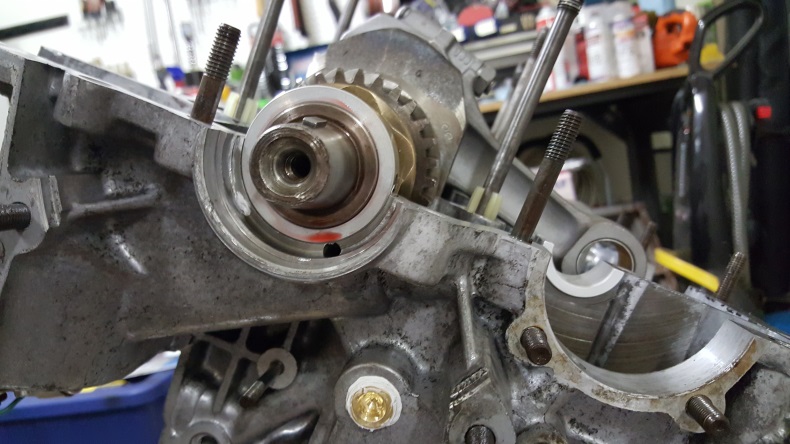

Don't forget to check your oil pump out,

And make sure your timing mark is er, marked accurately.

FWIW, I have never had any luck whatsoever getting paint or powder or polish or anything to stick to a mag fan shroud long term.

Oh, and yep, got the whole assembly balanced. Crank/flywheel/pressure plate/fan, and bolts. And rods and pistons balanced.

So, question...

I just got both case halves mated, with a thin coat of Permatex form a gasket. I put my flywheel on so I could more easily rotate the crankshaft to check for any binding. So....how easily should it turn? Mine turns, and doesn't feel like it's binding. But it does feel tighter than it did when turning it prior to both case halves being on it (which sounds completely reasonable, but...I'm just a bit paranoid at the moment).