T4 Tear Down / Rebuild in Jax FL

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: T4 Tear Down / Rebuild in Jax FL

Based on the photos it looks much better.

Do you have enough exposed threads for adjustment range as Ray noted?

(exhaust valve stems typically stretch over time//heat cycles)

I found that .080" shims under the rockers is usually a good starting point.

...about same thickness as a Tractor Supply 3/8" SAE grade 8 flat washer.

Do you have enough exposed threads for adjustment range as Ray noted?

(exhaust valve stems typically stretch over time//heat cycles)

I found that .080" shims under the rockers is usually a good starting point.

...about same thickness as a Tractor Supply 3/8" SAE grade 8 flat washer.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

Thank you for the reminder. So the thought here is to space the rocker assembly out a bit, in addition to turning the adjusters so that they have more threads between the rocker arm and valve (which allows for more room for adjustments when the valves stretch)? OK.Piledriver wrote: ↑Tue Nov 28, 2017 7:15 pm Based on the photos it looks much better.

Do you have enough exposed threads for adjustment range as Ray noted?

(exhaust valve stems typically stretch over time//heat cycles)

I found that .080" shims under the rockers is usually a good starting point.

...about same thickness as a Tractor Supply 3/8" SAE grade 8 flat washer.

Does that mean it's OK to cover the rocker arm oil hole?

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: T4 Tear Down / Rebuild in Jax FL

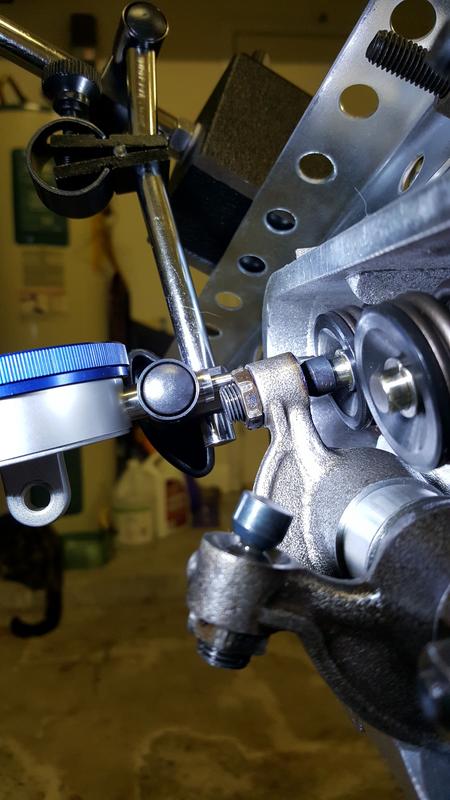

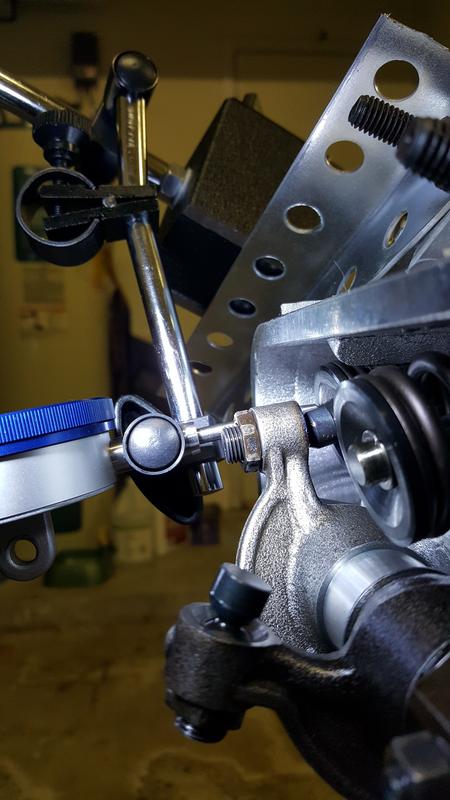

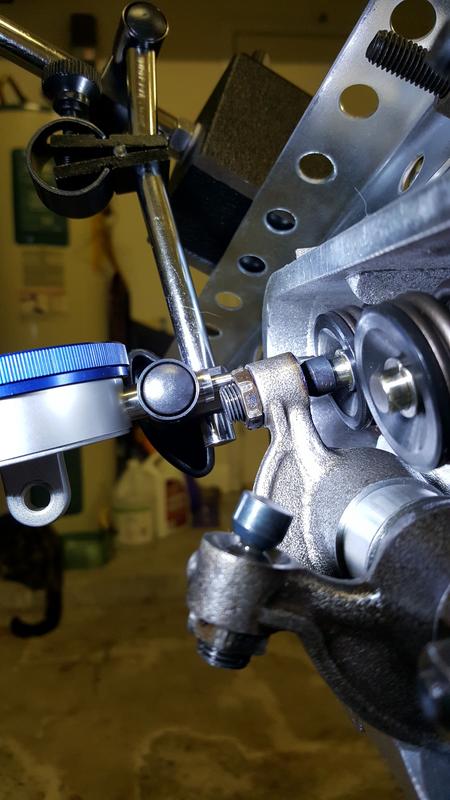

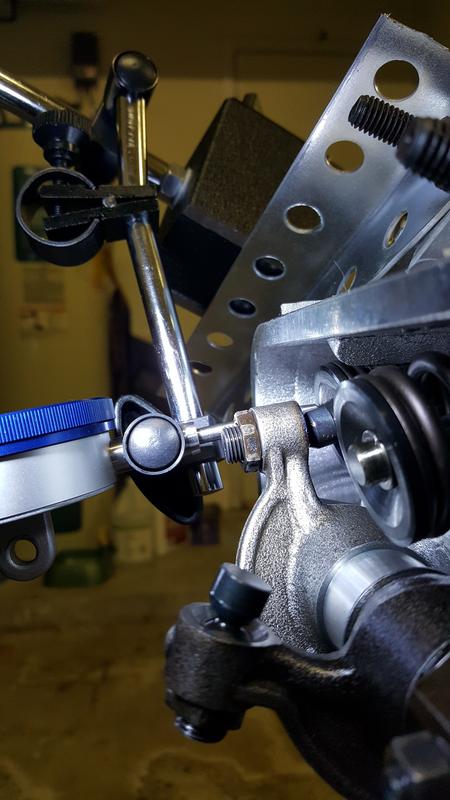

The spacers are actually to help fix the geometry.

A swivel foots pivot point is at the center of the ball (similar to a roller rocker geometry wise) rather than at the face of the valve. The spacers largely correct for this.

I don't see how blocking an oil passage would help anything, photos please.

I have cut a very narrow slot in the thread to direct the oil towards the valve spring etc.

It may even help...

A swivel foots pivot point is at the center of the ball (similar to a roller rocker geometry wise) rather than at the face of the valve. The spacers largely correct for this.

I don't see how blocking an oil passage would help anything, photos please.

I have cut a very narrow slot in the thread to direct the oil towards the valve spring etc.

It may even help...

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

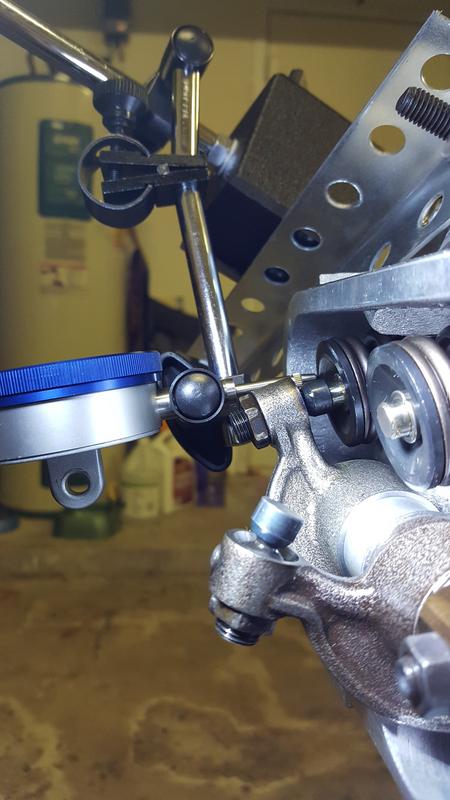

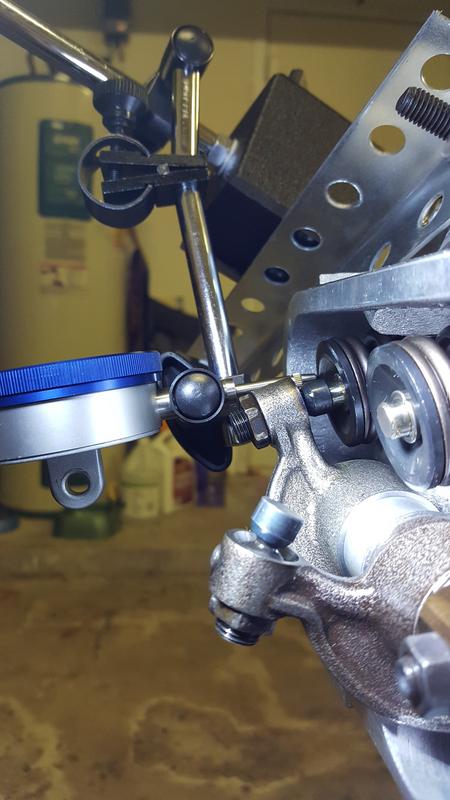

Found the SAE grade 8, 3/8 washers at Lowes, turned the adjusters in a bit more, extended the length of my push rod tool by about the same 2mm as the washers/spacers, re-measured for half lift, and tested this setup on both intake and exhaust valves...

Here are the results:

Exhaust

Zero lift:

Half lift:

Full lift:

Intake

Zero lift:

Half lift:

Full lift:

Oh, and I realized the ignorance of my rocker oil hole question after thinking about it. Stock adjusters always have their threads over the oil hole. I'll cut a small groove in the swivel foot adjuster threads like you and Clatter have mentioned.

My end-to-end push rod tool measurement came to 274 mm.

Here are the results:

Exhaust

Zero lift:

Half lift:

Full lift:

Intake

Zero lift:

Half lift:

Full lift:

Oh, and I realized the ignorance of my rocker oil hole question after thinking about it. Stock adjusters always have their threads over the oil hole. I'll cut a small groove in the swivel foot adjuster threads like you and Clatter have mentioned.

My end-to-end push rod tool measurement came to 274 mm.

Last edited by analogtherapy on Thu Apr 26, 2018 9:34 am, edited 1 time in total.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: T4 Tear Down / Rebuild in Jax FL

Looks mo betta.

Hows the lift vs cam spec?

Hows the lift vs cam spec?

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

Man am I glad you asked that question. I wasn't aware that that was something I should be checking!

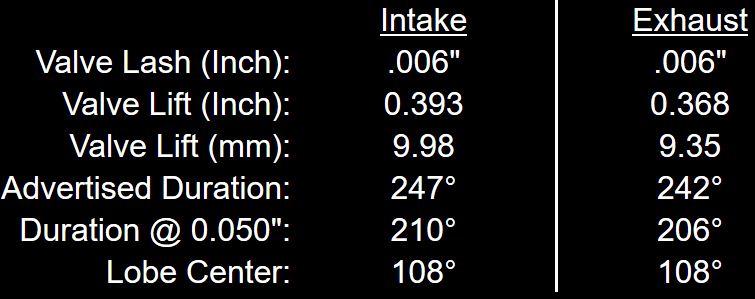

This is a Web Cam 142 stock grind. Copied from their page, here are the specs:

So intake @ .393 in, and exhaust @ .368 in.

I just measured and my results are:

Intake @ .392

Exhaust @ .362

Does this mean I need different push rod lengths, or is this close enough?

Last edited by analogtherapy on Thu Apr 26, 2018 9:35 am, edited 1 time in total.

-

_thesatanicmechanic

- Posts: 9

- Joined: Sat Oct 28, 2017 7:00 pm

Re: T4 Tear Down / Rebuild in Jax FL

That's lift measured at the valve or the pushrod? The specs and your readings...

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

I measured from the valve

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: T4 Tear Down / Rebuild in Jax FL

Sounds OK, error is in the noise.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

OK cool.

When setting the geometry, should I make sure that when at zero lift I have the .006 lash? Or set the geometry, and then back the adjuster out to get to the .006? Seems like a stupid question, but I just want to be sure before I have these push rods cut.

When setting the geometry, should I make sure that when at zero lift I have the .006 lash? Or set the geometry, and then back the adjuster out to get to the .006? Seems like a stupid question, but I just want to be sure before I have these push rods cut.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: T4 Tear Down / Rebuild in Jax FL

When you get that close don't sweat it.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

I couldn't leave well enough alone....

I mocked everything back up again, but this time made sure to leave .006 lash between the adjuster and valve stem when at zero lift. But now I can't seem to get back to .368 lift (for exhaust. I didn't re-measure intake yet). I now get .343. I tried changing the push rod tool, but got the same number again, despite a different length.

What am I doing wrong?

I mocked everything back up again, but this time made sure to leave .006 lash between the adjuster and valve stem when at zero lift. But now I can't seem to get back to .368 lift (for exhaust. I didn't re-measure intake yet). I now get .343. I tried changing the push rod tool, but got the same number again, despite a different length.

What am I doing wrong?

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

I think I'm over thinking this...

When the engine heats up, lash will be reduced, and the valve lift numbers will be at manufacturers spec.

New builder paranoia here

When the engine heats up, lash will be reduced, and the valve lift numbers will be at manufacturers spec.

New builder paranoia here

- Lo Cash John

- Posts: 1089

- Joined: Thu Jun 14, 2001 12:01 am

Re: T4 Tear Down / Rebuild in Jax FL

Man, from here at my laptop that's looking pretty close. If you need to shorten that adjustable pushrod let me know.

- analogtherapy

- Posts: 80

- Joined: Sat Apr 22, 2017 6:45 am

Re: T4 Tear Down / Rebuild in Jax FL

Hey John, how've you been?!Lo Cash John wrote: ↑Thu Dec 07, 2017 9:57 pm Man, from here at my laptop that's looking pretty close. If you need to shorten that adjustable pushrod let me know.

Yea, after getting everything measured, and coming up with the push rod length of 274 mm, I did it all again and got 275 mm. With things having been checked multiple times, and getting a measurement that close I felt confident about it and shipped the push rods off to EMW to get cut.

Hopefully, once I get them back things should start picking up! I suspect my next big step (after putting the engine back in) will be tuning the carbs.