Glenn wrote:There's been alot of confusion and problems with the 2 different styles of pressure plate / throwout bearing combos.

There's the "early" style, 1970 and older, which required a "centering ring" on the pressure plate.

There's the "late" style, 1971-1979, which has a sleeve on the tranny and no centering ring on the pressure plate.

Early:

Throwout bearing

Pressure plate (note centering ring)

Late:

Throwout bearing (note sleeve around the input shaft)

Pressure plate (note NO centering ring)

Don't rely on the year of the car. As we all know many times the engine and tranny have been swapped so you need to visually inspect the parts.

If you take the centering ring off and have a early throwout bearing, it will quickly fail.

If you leave the centering ring on and have a late throwout bearing you wan't be able to get the engine all the way on the input shaft when reinstalling the engine.

Here's a early throwout bearing:

Here's a late throwout bearing:

Also note that most pressure plates come with the centering ring already on it. If you have a late throwout bearing you can remove the ring. This allows the vendors to carry one part from all years.

This is the centering ring and the late model sleeve. They do not work together.

Any questions?

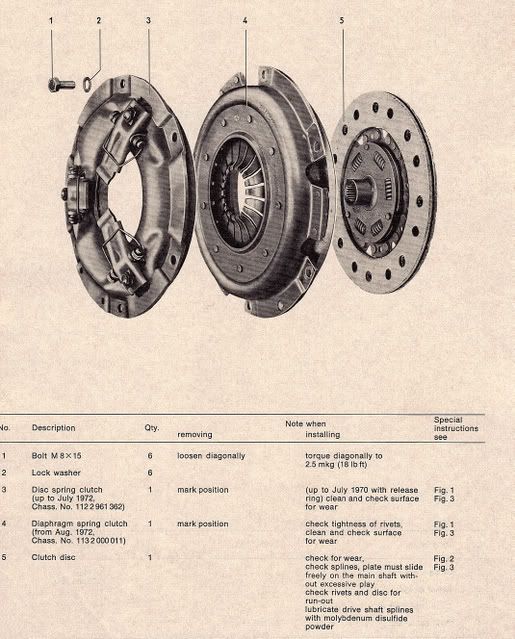

Exploded Views of Clutch Components

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

Exploded Views of Clutch Components

Last edited by david58 on Sun Apr 06, 2008 11:08 pm, edited 7 times in total.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

-

Chris V

- Posts: 3391

- Joined: Tue Sep 03, 2002 12:01 am

Other things to keep in mind...

1) The late model throw-out guide tube that bolts on using three M7x1.0 bolts appeared in `71, but `70 cases had the boss - just needs to be drilled and tapped...but not too deep

2) Earlier cases can be adapted to use last style throw-out guide tube by way of an aftermarket seal that incorporates a guide-tube into it.

3) An early pressure plate may be used with a late thrust if the ring is removed...sometimes it's necessary to clearance the 'fingers' for the guide-tube.

1) The late model throw-out guide tube that bolts on using three M7x1.0 bolts appeared in `71, but `70 cases had the boss - just needs to be drilled and tapped...but not too deep

2) Earlier cases can be adapted to use last style throw-out guide tube by way of an aftermarket seal that incorporates a guide-tube into it.

3) An early pressure plate may be used with a late thrust if the ring is removed...sometimes it's necessary to clearance the 'fingers' for the guide-tube.

http://www.joesracing.com/

Son of Marc

Son of Marc

- Leatherneck

- Moderator

- Posts: 17104

- Joined: Sat Jul 01, 2006 6:47 pm

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

Guys we are trying to make a sticky for the STF. I locked some threads in the Newbie Forum so I could work with them and make click-able links. This does not mean I don't want help in making the sticky. Please add info in the thread called:

Calling All STF Members Need Your Help Making a STF Sticky

http://www.shoptalkforums.com/viewtopic.php?t=115991

Calling All STF Members Need Your Help Making a STF Sticky

http://www.shoptalkforums.com/viewtopic.php?t=115991

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

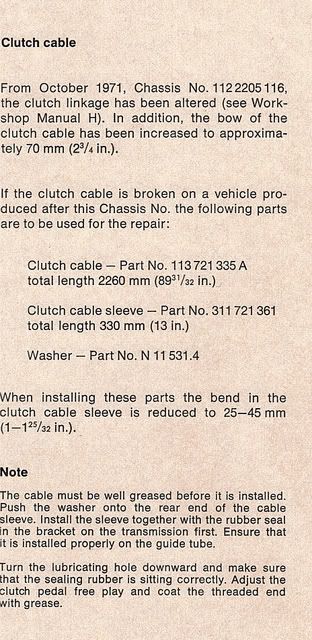

perrib wrote:Ever wonder why that CC seem just a bit short or long.

It is because VW had a sick sense of humor and the person who labeled your CC took advantage of it.

113 721 335 A 2250 mm up to 61

117 721 335 A 2260 mm 62-71

There are vin split years I will see if I can find it.

117 721 335 C 2281mm 72-74

111 721 335E 2268mm 74-79

Would the mods make this a sticky.

Marc wrote:I think if you'll take a good look at the two pans you'll see a subtle difference in the length of the clutch tube that protrudes out of the back of the tunnel. There are three bowden tube lengths and six different cables, and the changeover dates for the cables and tubes do not always correspond (another factor in cable selection is the length of the release arm on the cross-shaft and the length of the "hook" on the pedal - both got longer as years passed). Why did they go back & forth in the `70s? I dunno, possibly in an attempt to unify the Type I and II bowden tube lengths and/or to work better with the more compliant `73-up trans mounts. The rubber sheath is there to protect the tube and the trans case from chafing where they rub together - it was pretty stationary on OEM Bowden tubes, on the cheap-ass replacement ones available today you need to position it and secure it with tape or Ty-raps.

Bowden tubes:

311 721 361...-`71 T1, -`67 T2, & T3 and some `74 T1 (From 1x42398011 to 1x42663259) 13-1/8", long at bracket

211 721 361D (or A)...`72-early`74 (thru 1x42398010) T1 and `68-`79 T2 14-1/4"

111 721 361E...late`74 (From 1x42663260) -up T1 13-1/4", short at bracket

Cables:

111 721 335 thru 1960 and 1962 - 1963½ (ch#5 261 829)

111 721 335A 1961 only 2250mm

113 721 335 1963½ (ch# 5 261 830) - 1966

113 721 335A 1967 - 1971 2260mm

111 721 335C 1972 - 1974 (to 1x42663259) 2281mm

111 721 335E 1974 (from 1x42663260) - 1979 2268mm

113 721 335 was 2258mm (virtually the same as the 113 721 335A) and

111 721 335 was the same length as the 111 721 335E so those part numbers aren't stocked much anymore.

The earlier cables had a shorter shank on the eye at the front so when substituting a late cable in an early chassis you need to watch out for interference with the front of the clutch tube.

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

dan macmillan wrote:The forks are different. Early ones have a semicircle cutout for the bearing. No centering tube.

61-70 17mm shaft

Later ones are flater with a reverse curve where the bearing sits.

Used with centering tube.

71-10/72 17mm shaft

Centering tube 71-79

After 10/72 the shaft gets bigger.

11/72-79 20mm shaft

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

Re: Exploded Views of Clutch Components

Clutch Throw-Out Bearings and Shafts Exploded Diagram

#1 Throw-Out Bearing

#2 Retaining Spring

#3 Right Bushing

#4 Clutch Operating Shaft

#5 Snap Ring

#6 Washer

#7 Rubber Bushing

#8 Left Bushing

#9 Rubber Bushing

#10 Seat for Spring

#11 Clutch Return Spring

#12 Clutch Operating Lever

#13 Retaining Ring

#14 Locking Screw

#15 Retaining Ring

#16 Clutch Operating Lever

#17 Spring on Clutch Return Lever

#18 Seat for Spring

#19 Bushing

#20 Washer

#21 Snap Ring

#22 Clutch Fork

#23 Retaining Spring Clips

#24 Release Bearing

#25 Special 3-hole Washer Plate

#26 Hex Head Bolt (M7-15mm)

#27 M7 Hex Nut

#28 Locking Washer

#29 Throw-Out Bearing Guide Sleeve

#30 Snap Ring

#31 Washer

#32 Rubber Washer

#33 Bushing

#34 Rubber Washer

#35 Clutch Operating Shaft (Autostick)

#36 Release Bearing (Autostick)

#37 Bushing (Autostick)

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

Re: Exploded Views of Clutch Components

This is the type of clutch fork and throwout bearing I have.

I need a centering ring collar that goes on the pressure plate. This one in the next two pics is non removable.

I need one like the one below.

Does anyone know the part number on the collar? Or PM me if you have one that you don't need.

I need a centering ring collar that goes on the pressure plate. This one in the next two pics is non removable.

I need one like the one below.

This is the clutch I have Sachs part # 311 141 025EBR 2oomm on the box it has a sticker that says with collar. But it doesn't have the collar.Leatherneck wrote:To install or remove this you carefully grab hold of the center spiral spring lift it up over the finger and twist it in the off direction, to install it start the other end and slowly turn it till it threads itself on. Easy to do, ever take one off just save it you might need it in the future.

Does anyone know the part number on the collar? Or PM me if you have one that you don't need.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- Lotrat

- Posts: 4975

- Joined: Sat Mar 29, 2008 11:43 pm

Re:

Does the size of the clutch arm need to taken into account here?david58 wrote:perrib wrote:Ever wonder why that CC seem just a bit short or long.

It is because VW had a sick sense of humor and the person who labeled your CC took advantage of it.

113 721 335 A 2250 mm up to 61

117 721 335 A 2260 mm 62-71

There are vin split years I will see if I can find it.

117 721 335 C 2281mm 72-74

111 721 335E 2268mm 74-79

Would the mods make this a sticky.Marc wrote:I think if you'll take a good look at the two pans you'll see a subtle difference in the length of the clutch tube that protrudes out of the back of the tunnel. There are three bowden tube lengths and six different cables, and the changeover dates for the cables and tubes do not always correspond (another factor in cable selection is the length of the release arm on the cross-shaft and the length of the "hook" on the pedal - both got longer as years passed). Why did they go back & forth in the `70s? I dunno, possibly in an attempt to unify the Type I and II bowden tube lengths and/or to work better with the more compliant `73-up trans mounts. The rubber sheath is there to protect the tube and the trans case from chafing where they rub together - it was pretty stationary on OEM Bowden tubes, on the cheap-ass replacement ones available today you need to position it and secure it with tape or Ty-raps.

Bowden tubes:

311 721 361...-`71 T1, -`67 T2, & T3 and some `74 T1 (From 1x42398011 to 1x42663259) 13-1/8", long at bracket

211 721 361D (or A)...`72-early`74 (thru 1x42398010) T1 and `68-`79 T2 14-1/4"

111 721 361E...late`74 (From 1x42663260) -up T1 13-1/4", short at bracket

Cables:

111 721 335 thru 1960 and 1962 - 1963½ (ch#5 261 829)

111 721 335A 1961 only 2250mm

113 721 335 1963½ (ch# 5 261 830) - 1966

113 721 335A 1967 - 1971 2260mm

111 721 335C 1972 - 1974 (to 1x42663259) 2281mm

111 721 335E 1974 (from 1x42663260) - 1979 2268mm

113 721 335 was 2258mm (virtually the same as the 113 721 335A) and

111 721 335 was the same length as the 111 721 335E so those part numbers aren't stocked much anymore.

The earlier cables had a shorter shank on the eye at the front so when substituting a late cable in an early chassis you need to watch out for interference with the front of the clutch tube.

I have a 1972 Bug (2/72 VIN 1122505xxx) which should use the 2281mm cable. The cable I removed from the bug was 25mm shorter than the new one. The wingnut was in the middle of the threads, so it must be correct. The "correct" cable had the wingnut bottomed out on the threads. The 67-71 cable at 2260mm is a closer fit. At some point the transaxle must have been changed which has the shorter arm on it or am I crazy? No need to answer that last question.

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

Re: Re:

Yes a different length arm will change the length of the clutch cable you need for you car. So you are not crazy. I have the same problem with my 74 the cable is too long. I rednecked it and it works fine.Lotrat wrote:

Does the size of the clutch arm need to taken into account here?

I have a 1972 Bug (2/72 VIN 1122505xxx) which should use the 2281mm cable. The cable I removed from the bug was 25mm shorter than the new one. The wingnut was in the middle of the threads, so it must be correct. The "correct" cable had the wingnut bottomed out on the threads. The 67-71 cable at 2260mm is a closer fit. At some point the transaxle must have been changed which has the shorter arm on it or am I crazy? No need to answer that last question.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.