Grooved Oil Piston: Threat or Menace?

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Grooved Oil Piston: Threat or Menace?

Old VW literature tells us the grooved oil piston was for single oil pressure relief cases and the shorter, solid (nongrooved pistons) for dual-relief cases.

As I read it, the grooved piston bled oil off to the cooler all of the time, to reduce engine oil temps.

I am aware because of the high-pressure oil pressure relief valve kits (springs and pistons), that lots of grooved pistons have been used in dual relief cases.

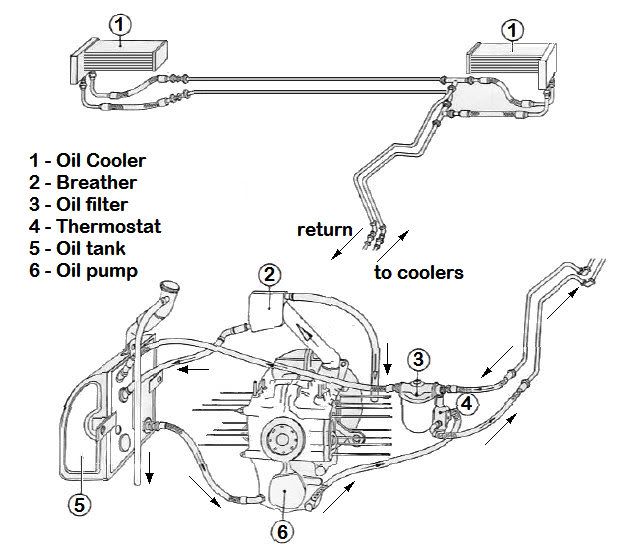

Now, on our mid-1970's IMSA Super Bug, we ran a front mounted oil cooler in the nose, fed by 1/2" ID hydraulic hoses from a common oil cooler adapter on top of the engine. I also had an oil filter plumbed into the oil OUT line, something I wouldn't do again, but I swear worked. The oil filter was behind the driver's seat, down low.

With a 26mm oil pump, we always had good oil pressure and great cooling.

Now, here's the question.

I need to mount an oil cooler (old school eight pass) in the nose of our Pan Am Ghia, and I want to feed it just like our IMSA Super Bug, off the oil cooler adapter.

So, the engine being a dual relief, would using a grooved piston help, in that it has the constant bleed to cooler and will fill the cooler lines on startup?

I am reasonably sure I used a grooved piston in the IMSA car. I remember how nervous I was about those long oil lines filling.

Thanks,

FJC

As I read it, the grooved piston bled oil off to the cooler all of the time, to reduce engine oil temps.

I am aware because of the high-pressure oil pressure relief valve kits (springs and pistons), that lots of grooved pistons have been used in dual relief cases.

Now, on our mid-1970's IMSA Super Bug, we ran a front mounted oil cooler in the nose, fed by 1/2" ID hydraulic hoses from a common oil cooler adapter on top of the engine. I also had an oil filter plumbed into the oil OUT line, something I wouldn't do again, but I swear worked. The oil filter was behind the driver's seat, down low.

With a 26mm oil pump, we always had good oil pressure and great cooling.

Now, here's the question.

I need to mount an oil cooler (old school eight pass) in the nose of our Pan Am Ghia, and I want to feed it just like our IMSA Super Bug, off the oil cooler adapter.

So, the engine being a dual relief, would using a grooved piston help, in that it has the constant bleed to cooler and will fill the cooler lines on startup?

I am reasonably sure I used a grooved piston in the IMSA car. I remember how nervous I was about those long oil lines filling.

Thanks,

FJC

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Grooved Oil Piston: Threat or Menace?

I cannot visualize the constant bleed to the oil cooler actually happening as described.

Need properly scaled graphics of the internals, would help everyone.

Any flow through the ~30 feet of line and cooler would be purely due to good intentions at high RPM unless force fed.

The 1500S pistons are TALLER IIRC, so I can see some benefit there from increased relief opening forcing oil to the cooler at lower temps.

I could see a constant bleed to the mains if you invert the piston and drill some holes in the now top/cup side of the piston for oil to pass into the mains.

(some SBC pump reliefs are set up this way)

This renders the oil cooler "control" into a simple pressure relief, and you could then hook your system up properly as a full flow with a real thermostat.

Running a long, restrictive loop just means most of the oil is going to skip the oil cooler unless the pressure relief piston is fully seated at the top.

When both passages are open, (probably all the time @ high RPM) oil will take the path of least resistance straight to the main gallery.

Need properly scaled graphics of the internals, would help everyone.

Any flow through the ~30 feet of line and cooler would be purely due to good intentions at high RPM unless force fed.

The 1500S pistons are TALLER IIRC, so I can see some benefit there from increased relief opening forcing oil to the cooler at lower temps.

I could see a constant bleed to the mains if you invert the piston and drill some holes in the now top/cup side of the piston for oil to pass into the mains.

(some SBC pump reliefs are set up this way)

This renders the oil cooler "control" into a simple pressure relief, and you could then hook your system up properly as a full flow with a real thermostat.

Running a long, restrictive loop just means most of the oil is going to skip the oil cooler unless the pressure relief piston is fully seated at the top.

When both passages are open, (probably all the time @ high RPM) oil will take the path of least resistance straight to the main gallery.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Grooved Oil Piston: Threat or Menace?

Keep the cooler lines short (and large) and duct the air instead.

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Grooved Oil Piston: Threat or Menace?

Hi Marc, Piledriver;

I absolutely agree on shorter lines. The cooler and fan on our Chump/LeMons SuperBug is fed off an oil cooler adapter, but the cooler and fan is inches ahead of the fan housing, blowing downward through a hole in the ex-luggage compartment area floor. Works great.

My need for the Historic Sportscar Racing crowd on the PanAm Ghia is to replicate the nose-mounted cooler as used by Porsche on the dry-sump 4-cam Spyders. The 4-cam actually had two coolers, both slightly larger than the doghouse coolers we have now, one under each headlight. The plumbing to these was mostly hardline and under half-inch ID.

I can get by with a single cooler. We are racing HSR again at Sebring (4th-7th Dec) and have been invited to show at Amelia Island in March. https://www.ameliaconcours.org

Blame this on "period correctness." At the moment, my decision is to use a grooved piston and a 32mm oil pump to push the oil on it's 24-foot round trip. The Sebring race will tell the tale, so here we go.

Thanks,

FJC

-

buildabiggerboxer

- Posts: 621

- Joined: Wed Mar 25, 2009 12:50 pm

Re: Grooved Oil Piston: Threat or Menace?

http://www.coolairvw.co.uk/Images/uploa ... dapter.pdf

I used this idea to good effect on my customer cup cars, albeit, the Bugpack version, we were not allowed to front mount coolers by the regs, but I did convert my own and other cars to front cooler after the series went more open regs, the series oil pump was retained, Melling, with a take off cover and the ' up port' plugged together with the pump body, both pump and cover were blue printed, prime, pressure, and cooling were all very good on only 1/2" , good quality braided line run through the car mounted on the tunnel passenger side, oil filter was mounted up front too.

I used this idea to good effect on my customer cup cars, albeit, the Bugpack version, we were not allowed to front mount coolers by the regs, but I did convert my own and other cars to front cooler after the series went more open regs, the series oil pump was retained, Melling, with a take off cover and the ' up port' plugged together with the pump body, both pump and cover were blue printed, prime, pressure, and cooling were all very good on only 1/2" , good quality braided line run through the car mounted on the tunnel passenger side, oil filter was mounted up front too.

- ONEBADBUG

- Posts: 213

- Joined: Wed Dec 02, 2009 9:25 pm

Re: Grooved Oil Piston: Threat or Menace?

My only input is that I have never been a fan of the full flow system that is commonly used. The reason is I don't like oil hoses, they leak, they can be damaged, and you have the dry start problem.

With that much hose, I would suggest using a carter fuel pump to fill the lines. Also, I recently found an oil filter that has a very positive check valve inside. I was having a problem with a Vanagon converted to a 2.0 ABA Golf engine that would dry start if it sat a few weeks.

With that much hose, I would suggest using a carter fuel pump to fill the lines. Also, I recently found an oil filter that has a very positive check valve inside. I was having a problem with a Vanagon converted to a 2.0 ABA Golf engine that would dry start if it sat a few weeks.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Grooved Oil Piston: Threat or Menace?

IIRC the Porsche used a dry sump. the cooler was in the scavenge circuit per typical practice?

I think the logic is that it will still flow fine with ~zero backpressure, just dumping back to the drysump tank, rather than feeding bearings.

I'd suggest the same with the CB drysump pump, but I'm not sure the 26mm scavenge stage would be enough unless one plugged the body (due to typically horrible fit/seal to case) and used an external inlet and outlet... Doable on both stages with some effort.

"Period" is cool and all, but the stock muffler and big bore peashooters that cost you time last round was "period".

I'm sure no one would say a peep about a 96 plate cooler w/Maradyne fan beside the transmission.

Put the 2L in it too.

I think the logic is that it will still flow fine with ~zero backpressure, just dumping back to the drysump tank, rather than feeding bearings.

I'd suggest the same with the CB drysump pump, but I'm not sure the 26mm scavenge stage would be enough unless one plugged the body (due to typically horrible fit/seal to case) and used an external inlet and outlet... Doable on both stages with some effort.

"Period" is cool and all, but the stock muffler and big bore peashooters that cost you time last round was "period".

I'm sure no one would say a peep about a 96 plate cooler w/Maradyne fan beside the transmission.

Put the 2L in it too.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

shepherd

- Posts: 101

- Joined: Wed Nov 28, 2012 4:30 am

Re: Grooved Oil Piston: Threat or Menace?

I have not noticed a difference in warmup or operating temperature trying both the plain, and grooved pistons. I did find that many of the grooved pistons out there are aftermarket, and measure smaller than OEM parts. With an aftermarket grooved piston, my oil was running over 225º. Simply switching to a stock grooved piston dropped my operating temp to 210-15º. I run full flow AN-10 stainless lines to a cooler and thermostatic controlled Mocal cooler, fed by a blueprinted 26mm pump. I see instant pressure on start up, even when sitting for weeks.

-

shepherd

- Posts: 101

- Joined: Wed Nov 28, 2012 4:30 am

Re: Grooved Oil Piston: Threat or Menace?

A few bits of info I found on the other site, is it OK to link to it? Hope so..

http://www.thesamba.com/vw/forum/album_ ... id=1133881

The second pic suggests that the grooved piston wasn't just fitted to all single relief cases, right?

http://www.thesamba.com/vw/forum/album_ ... id=1133881

The second pic suggests that the grooved piston wasn't just fitted to all single relief cases, right?

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Grooved Oil Piston: Threat or Menace?

The slotted plunger was first adopted in the dual-carb 1500cc Type III engine, and is therefore commonly referred to as the "1500S" plunger. It was only used in single-relief cases, and not all of them.

In the "Blue" Bentley manual (`66-`69 Beetle/`Ghia) it is stated "In the 1500 engine, from chassis 117 054 916 and engine H0 225 117, piston (plunger) of oil pressure relief valve is modified. This version of piston has annular groove, which allows oil to pass directly to the sump, relieving pressure and lowering engine oil temperature."

The photo on the same page (copyright date 1972) showing the assembly order features the earlier, non-slotted plunger; a few pages prior there's a picture showing a 1500 engine case which does feature the slotted plunger.

In the Orange manual (`70-`79 Beetle/'Ghia) which should only be covering dual-relief engine cases, Bentley used a similar picture to show the assembly order, but this one (with a later 1974 copyright date) features the slotted plunger - it would've been appropriate in the Blue manual, but has no business being in the Orange one. The picture does not show the flywheel end of the case so you can't easily tell that it's a single-relief, but if you'll look closely you'll see the small-diameter oil pickup tube characteristic of pre`70 engines. On the same page there's another picture which clearly shows a dual-relief case, with non-slotted plungers in both positions. The inclusion of the inappropriate assembly-order picture has unfortunately left many folks with the impression that a slotted plunger is a valid configuration for a dual-relief case...IT IS NOT!

To be honest, I don't fully understand the function of the slot...evidently it's supposed to promote the reduction of pressure, which would result in the "uncooled" passage to the oil galleys closing off sooner so that oil is required to go through the cooler sooner - yet the increased length would seem to have the opposite effect. All I know is that the factory engineers thought it to be a worthwhile running change in the SINGLE relief engines, other than the misleading photo in the Orange Bentley I have never found any documentation to indicate that it should be used in a dual-relief case.

In the "Blue" Bentley manual (`66-`69 Beetle/`Ghia) it is stated "In the 1500 engine, from chassis 117 054 916 and engine H0 225 117, piston (plunger) of oil pressure relief valve is modified. This version of piston has annular groove, which allows oil to pass directly to the sump, relieving pressure and lowering engine oil temperature."

The photo on the same page (copyright date 1972) showing the assembly order features the earlier, non-slotted plunger; a few pages prior there's a picture showing a 1500 engine case which does feature the slotted plunger.

In the Orange manual (`70-`79 Beetle/'Ghia) which should only be covering dual-relief engine cases, Bentley used a similar picture to show the assembly order, but this one (with a later 1974 copyright date) features the slotted plunger - it would've been appropriate in the Blue manual, but has no business being in the Orange one. The picture does not show the flywheel end of the case so you can't easily tell that it's a single-relief, but if you'll look closely you'll see the small-diameter oil pickup tube characteristic of pre`70 engines. On the same page there's another picture which clearly shows a dual-relief case, with non-slotted plungers in both positions. The inclusion of the inappropriate assembly-order picture has unfortunately left many folks with the impression that a slotted plunger is a valid configuration for a dual-relief case...IT IS NOT!

To be honest, I don't fully understand the function of the slot...evidently it's supposed to promote the reduction of pressure, which would result in the "uncooled" passage to the oil galleys closing off sooner so that oil is required to go through the cooler sooner - yet the increased length would seem to have the opposite effect. All I know is that the factory engineers thought it to be a worthwhile running change in the SINGLE relief engines, other than the misleading photo in the Orange Bentley I have never found any documentation to indicate that it should be used in a dual-relief case.

- turbobaja

- Posts: 2826

- Joined: Fri Sep 14, 2007 4:56 pm

Re: Grooved Oil Piston: Threat or Menace?

After running the slotted plunger in a couple engines for years I've switched to running only NON-slotted plungers (Dual relief cases only here). My goal was to help oil temperature reach operating temps sooner, and a shorter plunger seems ~ the same as less spring tension overall which would allow the plunger to unseat easier, without needing more pressure. The plunger needs to be seated in the bore (as with low pressure at idle, etc.) to direct flow to the cooler rather than the main bearings directly. I run a 21mm pressure pump and therefore don't have crazy high oil pressures hot or cold. I've noticed my oil temps DO pick up faster since installing only NON-slotted plungers in both positions with OE springs. Once someone installs a hi-volume pump or stiffer springs in EITHER plunger bore, all bets are off, regardless of plunger design in my opinion. But, to be honest, I don't fully understand the reason for the slot eitherMarc wrote:To be honest, I don't fully understand the function of the slot...evidently it's supposed to promote the reduction of pressure, which would result in the "uncooled" passage to the oil galleys closing off sooner so that oil is required to go through the cooler sooner - yet the increased length would seem to have the opposite effect. All I know is that the factory engineers thought it to be a worthwhile running change in the SINGLE relief engines, other than the misleading photo in the Orange Bentley I have never found any documentation to indicate that it should be used in a dual-relief case.

Karl

DON'T QUIT

DON'T QUIT

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Grooved Oil Piston: Threat or Menace?

Hi,

This is as much fun as quantum mechanics.

I can understand how the grooved piston promotes confusion. The solid piston is an on-or-off device, and each phase makes sense.

Think of the on-off as yes-no. The grooved piston adds maybe to the yes-no! And the "maybe" phase is what's confusing. Oil is flowing to the cooler and to the bearings at the same time ... how can that be? Why?

Eigenstate! Something that is two conditions at the same time.

Actually, had a VW hot rodder invented the grooved piston, it would have been hailed a great speed part. Cut a groove, reduce oil temp. VW had higher oil temps with the dual carb pancake engines (before fuel injection) and the grooved piston diverted some oil to the cooler on startup, beginning cooling early. Then, as operating temp was reached and the piston was pushed all the way up by the spring diverting (almost) all of the oil to the cooler, the goove is just wide enough so that when engine RPM's peak and for a moment, oil pressure slightly depresses the piston, and oil is again sent both to the cooler and bearings at the same time rather than just one or the other.

But, the cooling advantage is only temporary. As in quantum science, observation changes the object's value. Once above 200 degrees F., and the load continues, the oil just gets hotter. Piston design is moot.

All I care about for our front mounted oil cooler is the grooved piston will start filling the oil lines while cold.

FJC

This is as much fun as quantum mechanics.

I can understand how the grooved piston promotes confusion. The solid piston is an on-or-off device, and each phase makes sense.

Think of the on-off as yes-no. The grooved piston adds maybe to the yes-no! And the "maybe" phase is what's confusing. Oil is flowing to the cooler and to the bearings at the same time ... how can that be? Why?

Eigenstate! Something that is two conditions at the same time.

Actually, had a VW hot rodder invented the grooved piston, it would have been hailed a great speed part. Cut a groove, reduce oil temp. VW had higher oil temps with the dual carb pancake engines (before fuel injection) and the grooved piston diverted some oil to the cooler on startup, beginning cooling early. Then, as operating temp was reached and the piston was pushed all the way up by the spring diverting (almost) all of the oil to the cooler, the goove is just wide enough so that when engine RPM's peak and for a moment, oil pressure slightly depresses the piston, and oil is again sent both to the cooler and bearings at the same time rather than just one or the other.

But, the cooling advantage is only temporary. As in quantum science, observation changes the object's value. Once above 200 degrees F., and the load continues, the oil just gets hotter. Piston design is moot.

All I care about for our front mounted oil cooler is the grooved piston will start filling the oil lines while cold.

FJC

- amskeptic

- Posts: 666

- Joined: Thu Oct 24, 2002 1:01 am

Re: Grooved Oil Piston: Threat or Menace?

Here is your definitive answer to exactly how the grooved piston gives better oil cooling.

Note: the groove only works at operating temperature.

http://www.itinerant-air-cooled.com/vie ... 46&t=12422

Note: the groove only works at operating temperature.

http://www.itinerant-air-cooled.com/vie ... 46&t=12422

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Grooved Oil Piston: Threat or Menace?

Hi AmSkeptic,

I think the illustrated example of the grooved piston you pointed out is excellent.

The statement on that site that more oil flows to the cooler because of the groove should be enough for 90% of the VW aficionados. In one sentence, that wraps it up.

I was being a bit tongue-in-cheek comparing the action of the groove to the eigenstate in Quantum mechanics, actually poking fun at the perceived mystery of the groove. If I were explaining to one of our younger RetroRacing apprentice mechanics how the groove works, I'd say:

"The groove converts what was a simple on-off function where cold oil flowing to the bearings was diverted to the cooler then to the bearings as the oil got hot, to a bleed-by situation that feeds both the bearings and the cooler most of the time."

Then I would tell the apprentice we don't use the grooved piston because we only use dual oil pressure relief cases. And we only use stock oil pressure relief springs. The high-pressure spring kits with the grooved pistons are for the old single-relief cases.

FJC

I think the illustrated example of the grooved piston you pointed out is excellent.

The statement on that site that more oil flows to the cooler because of the groove should be enough for 90% of the VW aficionados. In one sentence, that wraps it up.

I was being a bit tongue-in-cheek comparing the action of the groove to the eigenstate in Quantum mechanics, actually poking fun at the perceived mystery of the groove. If I were explaining to one of our younger RetroRacing apprentice mechanics how the groove works, I'd say:

"The groove converts what was a simple on-off function where cold oil flowing to the bearings was diverted to the cooler then to the bearings as the oil got hot, to a bleed-by situation that feeds both the bearings and the cooler most of the time."

Then I would tell the apprentice we don't use the grooved piston because we only use dual oil pressure relief cases. And we only use stock oil pressure relief springs. The high-pressure spring kits with the grooved pistons are for the old single-relief cases.

FJC