Above: Two things to fix, the crank pulley and the oil pump cover plate

UpFixing the CB Performance Dry Sump Oil Pump Kit

The CB Performance Dry Sump Oil Pump kit is simple and easy to install, but our experience with them over the years in several engines has revealed two issues that need fixing, one critical, one more of a refinement.

We had recurring problems from the beginning with the press-in oil seal spinning with the crank pulley and leaking oil. Press-in seals are more commonly know as sand seals, and not most engine builder's favorite type of part. "Real" sand seals are machined into the engine case.

On the subject of sand seals, an interesting bit of trivia is the VW engine actually intakes air around the stock crank pulley hub. It has no oil seal. While most VW guys know about the factory design of threads on the pulley hub to "screw" oil back inside the engine that escapes the oil slinger, they are not aware why VW designed the case without a crank pulley oil seal. The air intake around the stock pulley hub normalizes crankcase pressure and helps the venting of vapor and pressure up and out the alternator stand vent tube.

Dune buggy builders soon discovered that the case ingested sand around the pulley hub and the machined-in sand seal was invented. The Porsche 356, once the factory adopted the 3-piece case, has an oil seal behind the crank pulley. To compensate for lack of ventilation breathing, a series of valve cover vent designs were tried. The winner was a vent tube directly in the top of the head (not the valve cover) with a hose feeding to the carb's air filter housing.

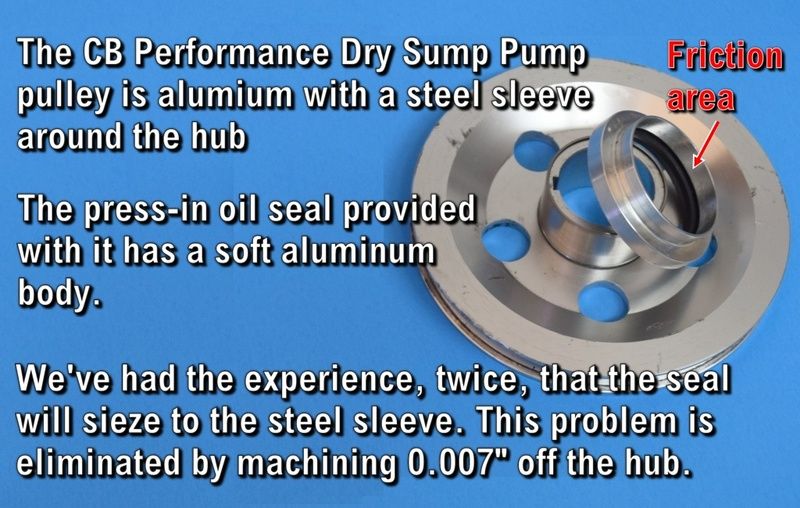

Above: Fixing the crank Pulley

Once during a 14-Hour LeMons enduro, we had seal after seal seize to the pulley hub, spinning the seals, and causing big oil leaks. In desperation, we jammed the pulley down on the nose of a drill motor and with a flat file turned down the hub just enough to clear the seal.

But on two other occasions, with newer but unmodified parts, with the seals firmly JB-Welded in place, we had the seal absolutely weld itself to the hub, ruining the seal and holding on so tight the engine would either not spin over or hold the crank so tightly it felt as if the engine was locked up. And we have a high-torque geared starter.

That is serious friction. And a testimonial to JB Weld!

The permanane fix was to machine 0.007" off all our new pulley hubs. With that clearance, the oil seal still seals and the engine turns easily. Problem solved.

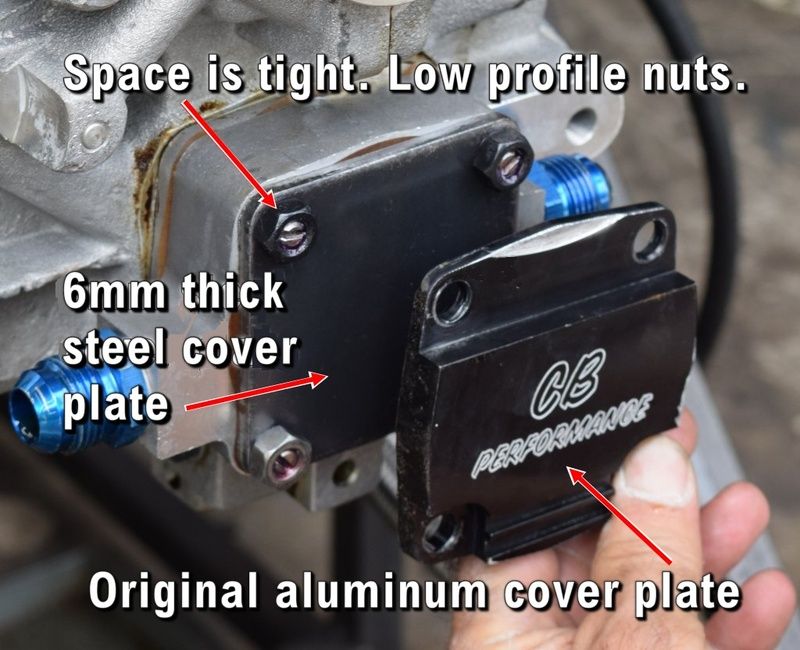

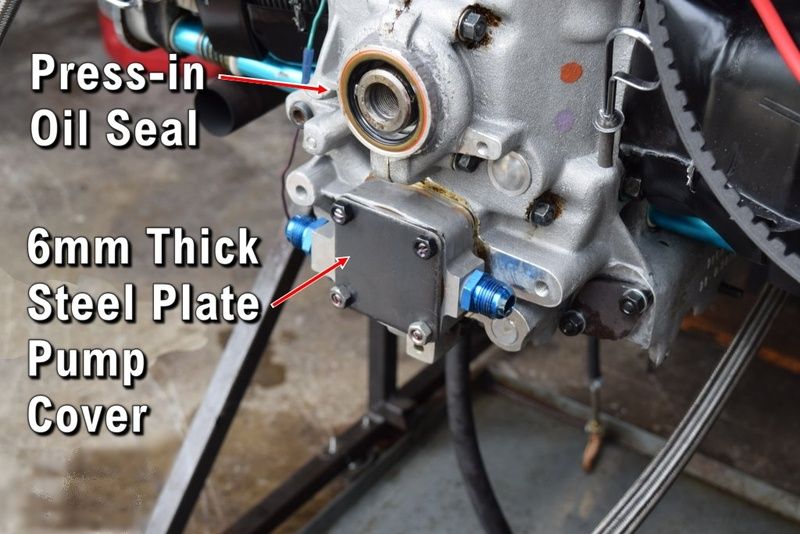

Above: Replacing the pump cover plate

Aluminum is not a good material for oil pump cover plates. The steel pump gears eat into the softer aluminum, and at some point, the headspace becomes wide enough for oil pressure to bleed around the gears, and you slowly loose oil pressure.

VW and Porsche always used steel pump covers to reduce wear, and even then it was a good idea to flat face the steel pump covers from time to time.

EMPI sells a simple unpainted steel pump cover (part number 9148-7) just 6mm slim, that if used with low-profile valve adjuster nuts on the top two studs, fits under the installed pulley like it was made for it.

FJC