Engine/Oil Help

-

cvbug

- Posts: 14

- Joined: Wed Sep 12, 2012 12:14 pm

Engine/Oil Help

So I'll start off by saying I have made use of the search feature here and other sites and I just can't get the answer I am looking for.

I have just completed about 90% of my build on a 68 bug and can now drive the car while I complete the rest. The problem is when the engine gets hot, I have what seems to be no oil pressure either on the gauge or idiot light. I'm using 10/40 oil with the zinc adititive for now. The engine was rebuild new by a reputable engine builder about 10 yrs ago and stored in a bag in the garage. It's a dual relief 1600 with single port heads, straight cut time gears and I'm told a 110 cam. It has a pict 31 carb and a 009 distributor. Also I used an electric fuel pump under the tank to supply the gas. And even though it drives great and has lots of power, after a long drive it will make a grawl sound when I turn it off and theres the smell of gas.

It has a dog house style oil cooler with a home built hoover mod. And all the engine cooling tins are in place and are new along with all the engine seals.

1. Would using 20/50 instead of 10/40 make a differance with the oil issue.

2. Would a higher pressure oil pump and the 10/40 be a better choice.

The plan for this car is to be a daily driver and right now it scares me a little that I could be damaging the new engine. Like I stated first I have read every thing I could find about oil types, pressure issues and coolers and I just cant find the answer. I hope that this post will answer my question and fix my problem and possibly help many other people with similar issues.

I have just completed about 90% of my build on a 68 bug and can now drive the car while I complete the rest. The problem is when the engine gets hot, I have what seems to be no oil pressure either on the gauge or idiot light. I'm using 10/40 oil with the zinc adititive for now. The engine was rebuild new by a reputable engine builder about 10 yrs ago and stored in a bag in the garage. It's a dual relief 1600 with single port heads, straight cut time gears and I'm told a 110 cam. It has a pict 31 carb and a 009 distributor. Also I used an electric fuel pump under the tank to supply the gas. And even though it drives great and has lots of power, after a long drive it will make a grawl sound when I turn it off and theres the smell of gas.

It has a dog house style oil cooler with a home built hoover mod. And all the engine cooling tins are in place and are new along with all the engine seals.

1. Would using 20/50 instead of 10/40 make a differance with the oil issue.

2. Would a higher pressure oil pump and the 10/40 be a better choice.

The plan for this car is to be a daily driver and right now it scares me a little that I could be damaging the new engine. Like I stated first I have read every thing I could find about oil types, pressure issues and coolers and I just cant find the answer. I hope that this post will answer my question and fix my problem and possibly help many other people with similar issues.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Engine/Oil Help

Dunno what the "grawl" might be...can you elaborate? Does it change if the clutch pedal's depressed, for example?

As for the smell, the most likely cause would be a little leak downstream of the electric pump. A small one won't leave any puddles. First thing I'd do is crawl under and check at both ends for a damp hose. It could also be that the carb float valve isn't up to the task of controlling the pressure...which electric pump, exactly, is it? Any regulator installed?

I'll assume that you're aware of the importance of sealing up the engine compartment so that no hot air is recirculating from below - the fact that you know what a Hoover Bit is leads me to believe you're pretty savvy on that subject.

The average person's hands can tolerate holding onto something that's at 140°F or below indefinitely. As it happens, if the handle of your Type 1 engine's dipstick tube is below that temperature it's a fairly reliable indication that there's no overheating issue. If you grab the dipstick after you've been driving a while and can't hang on for more than a few seconds, you're running too hot for some reason.

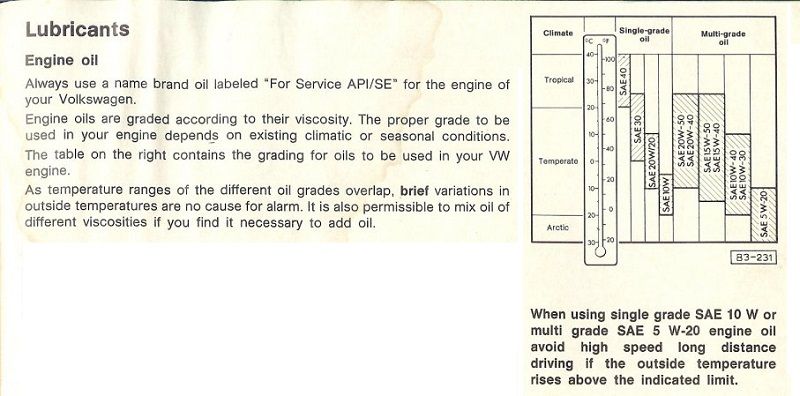

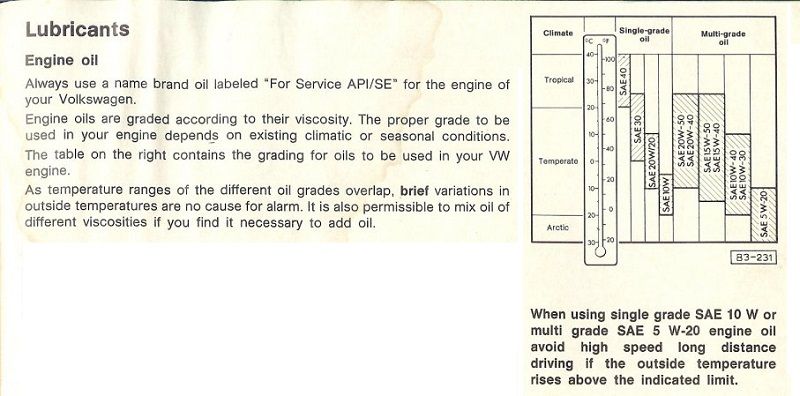

What oil pump's in it now? A 26mm should be adequate unless there are excessive internal clearances, most of the time all that a larger pump will do for you is waste power heating up the oil. 10W-40 should be thick enough for a fresh engine unless it's very hot outside.

Dual-relief cases have larger oil passages, so while a pre`70 311 115 107AK pump will fit & function its ports are smaller - you should have a 111 115 107AK (since you have straight-cut gears, the cam is a 3-rivet, "flat-faced" unit so the mid`71-up 111 115 107BK pump would not work) Not a likely cause of this particular symptom, but if you'll be pulling the pump it's something you should verify.

One common cause of low pressure at hot-idle is the incorrect pump cover gasket - the right one for the job is the tissue-thin one, if it's thicker the gears will have excessive endplay and bleed off pressure when the oil is thin. One would hope that a professional builder would know to use the thin one (and NOT use excessive sealant on it - if you can see goop exuding between the cover and the pump housing his qualifications become quite suspect).

Another possibility is that the builder used an aftermarket "pressure booster" kit. Except in extremely rare instances (with modified oil plumbing) these things are a complete waste of money, you're far better off with the stock, factory springs and non-slotted plungers.

Exactly what case do you have? If it's OEM, what's the ID letters/numbers? If there's no stamped-in ID, what's cast into the sides of the sump? Pictures may be helpful.

Note that when the engine displacement was increased to 1600cc in 1970 the factory engineers felt that a louvered engine lid was needed to ensure enough cooling air getting in...when the higher-output dualport heads were adopted, a wider fan that pumps more CFM was incorporated, and the louver area was increased over the years. You probably have the wide fan, so you should definitely have a louvered lid. If not, prop it open a bit with a tennis ball or Coke can and see if the symptom changes any. If you have an alternator, you should be running the wider 11.2x912La belt..and NO slippery chrome-plated pulleys in any case.

As for the smell, the most likely cause would be a little leak downstream of the electric pump. A small one won't leave any puddles. First thing I'd do is crawl under and check at both ends for a damp hose. It could also be that the carb float valve isn't up to the task of controlling the pressure...which electric pump, exactly, is it? Any regulator installed?

I'll assume that you're aware of the importance of sealing up the engine compartment so that no hot air is recirculating from below - the fact that you know what a Hoover Bit is leads me to believe you're pretty savvy on that subject.

The average person's hands can tolerate holding onto something that's at 140°F or below indefinitely. As it happens, if the handle of your Type 1 engine's dipstick tube is below that temperature it's a fairly reliable indication that there's no overheating issue. If you grab the dipstick after you've been driving a while and can't hang on for more than a few seconds, you're running too hot for some reason.

What oil pump's in it now? A 26mm should be adequate unless there are excessive internal clearances, most of the time all that a larger pump will do for you is waste power heating up the oil. 10W-40 should be thick enough for a fresh engine unless it's very hot outside.

Dual-relief cases have larger oil passages, so while a pre`70 311 115 107AK pump will fit & function its ports are smaller - you should have a 111 115 107AK (since you have straight-cut gears, the cam is a 3-rivet, "flat-faced" unit so the mid`71-up 111 115 107BK pump would not work) Not a likely cause of this particular symptom, but if you'll be pulling the pump it's something you should verify.

One common cause of low pressure at hot-idle is the incorrect pump cover gasket - the right one for the job is the tissue-thin one, if it's thicker the gears will have excessive endplay and bleed off pressure when the oil is thin. One would hope that a professional builder would know to use the thin one (and NOT use excessive sealant on it - if you can see goop exuding between the cover and the pump housing his qualifications become quite suspect).

Another possibility is that the builder used an aftermarket "pressure booster" kit. Except in extremely rare instances (with modified oil plumbing) these things are a complete waste of money, you're far better off with the stock, factory springs and non-slotted plungers.

Exactly what case do you have? If it's OEM, what's the ID letters/numbers? If there's no stamped-in ID, what's cast into the sides of the sump? Pictures may be helpful.

Note that when the engine displacement was increased to 1600cc in 1970 the factory engineers felt that a louvered engine lid was needed to ensure enough cooling air getting in...when the higher-output dualport heads were adopted, a wider fan that pumps more CFM was incorporated, and the louver area was increased over the years. You probably have the wide fan, so you should definitely have a louvered lid. If not, prop it open a bit with a tennis ball or Coke can and see if the symptom changes any. If you have an alternator, you should be running the wider 11.2x912La belt..and NO slippery chrome-plated pulleys in any case.

-

cvbug

- Posts: 14

- Joined: Wed Sep 12, 2012 12:14 pm

Re: Engine/Oil Help

I don't know how else to describe the sound except it's a growl. Kinda a dry metal moving part cry or a squeaky door hinge sound.

Here are some pictures.....

Engine Cover with Stand Offs to help with cooling.

Engine Number on case.....

Oil Pump Cover.....

Oil extra sump.....

Engine.....

Does any of these pictures help?

There is no leaking gas from the lines. So i'm going to look into a fuel regulator to help with the gas smell.

Here are some pictures.....

Engine Cover with Stand Offs to help with cooling.

Engine Number on case.....

Oil Pump Cover.....

Oil extra sump.....

Engine.....

Does any of these pictures help?

There is no leaking gas from the lines. So i'm going to look into a fuel regulator to help with the gas smell.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Engine/Oil Help

Clean looking motor, not a fan of gauze air filters, but to each his own.

(The stock late paper filter setup is (arguably) the best filter you could use for performance and filtration on that carb)

Could the noise possibly a bit of dieseling? (run-on as you lack the cutoff idle fuel jet)

The low oil pressure could be due to many things as already mentioned, but a hot engine is more likely to diesel a bit at shutoff.

RTV is not considered good form, as it is too easy to goop on, and it can get places it shouldn't.

Hmmm.... Get a std mechanical pressure guage on there temporarily, many people freak out over inaccurate VDO gauges/idiot light issues. VDO is generally dash filler quality "instrumentation". The one I had triggered the idiot light at 15 PSI and read zero below ~10 PSI. I threw it away, the std idiot light tells you all you really need to worry about.

Consider heating it up THEN swap a 0-30 gauge in for the hot idle test for better resolution. Don't rev it or you might bork it.

You may want to consider carrying a spare std Bosch distributor cap and rotor.

(The stock late paper filter setup is (arguably) the best filter you could use for performance and filtration on that carb)

Could the noise possibly a bit of dieseling? (run-on as you lack the cutoff idle fuel jet)

The low oil pressure could be due to many things as already mentioned, but a hot engine is more likely to diesel a bit at shutoff.

RTV is not considered good form, as it is too easy to goop on, and it can get places it shouldn't.

Hmmm.... Get a std mechanical pressure guage on there temporarily, many people freak out over inaccurate VDO gauges/idiot light issues. VDO is generally dash filler quality "instrumentation". The one I had triggered the idiot light at 15 PSI and read zero below ~10 PSI. I threw it away, the std idiot light tells you all you really need to worry about.

Consider heating it up THEN swap a 0-30 gauge in for the hot idle test for better resolution. Don't rev it or you might bork it.

You may want to consider carrying a spare std Bosch distributor cap and rotor.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Engine/Oil Help

Biggest problem I have with the aftermarket aircleaners is that most (like this one) sit too low and disrupt the fuel standoff fog that exists over the VW carb at speed - putting in a spacer tube to raise the aircleaner up a few inches will address that problem.

One reason for the bad rep of electric oil pressure gauges is that the senders can develop an air pocket. The big senders like this dual-function VDO unit are especially sensitive to the problem. The solution is to use an angled fitting so the sender can be oriented with its terminals pointed down, that way any air that gets into it has a chance of self-purging.

I'm a little leery of the "36HP" aftermarket shrouds but presumably when they designed this doghouse-style one they incorporated internal vanes which approximate those of an OEM DP shroud.

Oil pump installation looks legit. Hood standoffs eliminate the concern about louvers. I like the modified sled tins.

Did you or the builder put on the deep sump? Concern is that the pickup tube extension is installed right and not allowing air to suck in where it meets the stock pickup. Since the pickup is held down in place by one of the m6 strainer-plate studs and those are replaced with longer ones when installing most deep sumps, if that job's not done right the pickup tube can come loose where it plugs into the case near the pump - above the level of the oil. A suction-side leak, even if it's not bad enough to cause a complete loss of pump prime, will aerate the oil making it compressible and reducing its lubrication effectiveness (an ill-fitting pump that lets air in between it and the case can cause the same problem).

I share Piledriver's distrust of the sexy translucent distributor caps. When routing ignition cables one should avoid having them run closely together and parallel - that can cause inductive coupling between them, neat & tidy looking is not necessarily the best arrangement. You should be aware that inline fuel filters on the carb inlet have been implicated in more than a few engine fires (the inlet pipe is merely press-fit into the carb top and presumably the added mass of the filter can make it work loose)...so don't make things worse when you put in the regulator, you'll probably want to mount it to the firewall. Check that the fuel line is protected from being cut through where it passes through the front tin. Why on earth do you still have a `68/`69 diaphragm throttle positioner?

One reason for the bad rep of electric oil pressure gauges is that the senders can develop an air pocket. The big senders like this dual-function VDO unit are especially sensitive to the problem. The solution is to use an angled fitting so the sender can be oriented with its terminals pointed down, that way any air that gets into it has a chance of self-purging.

I'm a little leery of the "36HP" aftermarket shrouds but presumably when they designed this doghouse-style one they incorporated internal vanes which approximate those of an OEM DP shroud.

Oil pump installation looks legit. Hood standoffs eliminate the concern about louvers. I like the modified sled tins.

Did you or the builder put on the deep sump? Concern is that the pickup tube extension is installed right and not allowing air to suck in where it meets the stock pickup. Since the pickup is held down in place by one of the m6 strainer-plate studs and those are replaced with longer ones when installing most deep sumps, if that job's not done right the pickup tube can come loose where it plugs into the case near the pump - above the level of the oil. A suction-side leak, even if it's not bad enough to cause a complete loss of pump prime, will aerate the oil making it compressible and reducing its lubrication effectiveness (an ill-fitting pump that lets air in between it and the case can cause the same problem).

I share Piledriver's distrust of the sexy translucent distributor caps. When routing ignition cables one should avoid having them run closely together and parallel - that can cause inductive coupling between them, neat & tidy looking is not necessarily the best arrangement. You should be aware that inline fuel filters on the carb inlet have been implicated in more than a few engine fires (the inlet pipe is merely press-fit into the carb top and presumably the added mass of the filter can make it work loose)...so don't make things worse when you put in the regulator, you'll probably want to mount it to the firewall. Check that the fuel line is protected from being cut through where it passes through the front tin. Why on earth do you still have a `68/`69 diaphragm throttle positioner?

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Engine/Oil Help

darn, I missed the firestarter... gettin old.

As Marc noted, the little press-in fuel inlet fitting on the OG carbs tends to fall out...

There exist screw in fittings, and other solutions.

Put the filter up at the fuel pump, and replace all the hoses with something like Gates multi-fuel SAE30R7.

It wont fall apart after 6-8 months running E10 like the "oe german braided" or generic fuel line, and costs little more.

Also, make sure the coil/backup lights wire is fused. Its usually easy to identify, it's the black, krispy one.

There is a dedicated thread on "how not to burn down your VW" or some such, probably in the stickies that is good reading.

As Marc noted, the little press-in fuel inlet fitting on the OG carbs tends to fall out...

There exist screw in fittings, and other solutions.

Put the filter up at the fuel pump, and replace all the hoses with something like Gates multi-fuel SAE30R7.

It wont fall apart after 6-8 months running E10 like the "oe german braided" or generic fuel line, and costs little more.

Also, make sure the coil/backup lights wire is fused. Its usually easy to identify, it's the black, krispy one.

There is a dedicated thread on "how not to burn down your VW" or some such, probably in the stickies that is good reading.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Ol'fogasaurus

- Posts: 17756

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Engine/Oil Help

" ...Its usually easy to identify, it's the black, krispy [sic] one ..." Ya, you betcha! So funny an so correct.

-

cvbug

- Posts: 14

- Joined: Wed Sep 12, 2012 12:14 pm

Re: Engine/Oil Help

It will take me a few times to read and digest what has been said. The hole car was rewired with a StreetWorks wiring kit. I don't think the usual fire hazards will be present with old crispy wires.

I was unaware of the issue with the distributor cap and wires running together. I guess i'll take a look at some pictures and get some ideas. I'll also change the fuel fitter as recommended. Is there a good after market air cleaner?

So my gauges may not be telling me the truth? I really wanted to monitor the engine the best I can. This car is a big investment and I don't want to throw my money away.

Is there any way of nowing the oil pick up tube is correct with out opening the sump? I will be changing the oil soon since it was the break in oil, so when the covers off what should I look for? Should I still use 10/40?

I was unaware of the issue with the distributor cap and wires running together. I guess i'll take a look at some pictures and get some ideas. I'll also change the fuel fitter as recommended. Is there a good after market air cleaner?

So my gauges may not be telling me the truth? I really wanted to monitor the engine the best I can. This car is a big investment and I don't want to throw my money away.

Is there any way of nowing the oil pick up tube is correct with out opening the sump? I will be changing the oil soon since it was the break in oil, so when the covers off what should I look for? Should I still use 10/40?

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Engine/Oil Help

The oil level check is sort of self checking, when you do the oil change, put in 2.5l of oil.

See where the dipstick reads.... Wait, you will have to allow for the deep sump volume, but you get the idea.

One thing to look at when you change the oil is how the pickup tube extension is attached... IIRC they come with a hose clamp and duct tape

(Marc sort of mentioned this above)

Make sure it's attached and sealed properly, rubber gets old sitting around, might want to pull it and check it out, as if it has a crack/pinhole, the rest of the issues you have would logically follow. Some folks weld those on, but then you can't yank a cracked sump and still drive the car...

(I have never installed one of those as I have been running T4s for ages, but I have seen some done, badly)

See where the dipstick reads.... Wait, you will have to allow for the deep sump volume, but you get the idea.

One thing to look at when you change the oil is how the pickup tube extension is attached... IIRC they come with a hose clamp and duct tape

(Marc sort of mentioned this above)

Make sure it's attached and sealed properly, rubber gets old sitting around, might want to pull it and check it out, as if it has a crack/pinhole, the rest of the issues you have would logically follow. Some folks weld those on, but then you can't yank a cracked sump and still drive the car...

(I have never installed one of those as I have been running T4s for ages, but I have seen some done, badly)

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

cvbug

- Posts: 14

- Joined: Wed Sep 12, 2012 12:14 pm

Re: Engine/Oil Help

I took the car for a good drive today and then checked the oil dipstick. It wasn't that hot I could hold on to it no problem. So that kind of says there isn't an over heating problem....correct?

On my way back home though I stopped at a light and smoke started belowing from under the car and I had notice the car wasn't getting up to speed. Well turns out after I pulled to the side of the road that I had left the emergancy brake on for the last 2 miles and the rear brakes were burning paint off the drums. WHOOOPS!!!

I still have the oil light/pressure issue. So I am going to try 20/50 this weekend and see how the car likes it.

On my way back home though I stopped at a light and smoke started belowing from under the car and I had notice the car wasn't getting up to speed. Well turns out after I pulled to the side of the road that I had left the emergancy brake on for the last 2 miles and the rear brakes were burning paint off the drums. WHOOOPS!!!

I still have the oil light/pressure issue. So I am going to try 20/50 this weekend and see how the car likes it.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Engine/Oil Help

You may take some flack for that, but IMO there's nothing wrong with running 20W-50 in a Type I during warm weather - this is an ancient, low-pressure design - far removed from current engineering that uses high pressure to get away with thin-n-n-n oil to pull better fuel economy numbers on the federal dyno tests. Come the first morning frost in the fall you should switch to a lower viscosity. Revving a cold engine with 20W-50 can overpower the capacity of the pressure control valve relief drilling and damage your cooler or cooler seals, so avoid that in the event of an unexpected cold snap when you're still running "summer" oil.

As far as the gauge accuracy goes, it's wise to always be a little skeptical of any electric gauge until you've verified its accuracy by comparing to a mechanical gauge but generally VDOs are pretty good (barring the air-bubble syndrome I mentioned above). While the dual-function sender makes for a clean-looking installation, it is putting all your eggs in one basket...I'd rather use a tee fitting so I can have an independent sender for the warning light. The stock 021 919 081B sender triggers at .15 to .45 Bar (2.2 to 6.6 PSI); at a normal idle speed of around 875 RPM, oil pressure should be slightly higher than that (~7 PSI)...just after a hard highway run, the first few times you come to a stop the lamp may flicker at idle - that's normal, give it a little gas to increase the fan speed until the residual heat has dissipated.

As far as the gauge accuracy goes, it's wise to always be a little skeptical of any electric gauge until you've verified its accuracy by comparing to a mechanical gauge but generally VDOs are pretty good (barring the air-bubble syndrome I mentioned above). While the dual-function sender makes for a clean-looking installation, it is putting all your eggs in one basket...I'd rather use a tee fitting so I can have an independent sender for the warning light. The stock 021 919 081B sender triggers at .15 to .45 Bar (2.2 to 6.6 PSI); at a normal idle speed of around 875 RPM, oil pressure should be slightly higher than that (~7 PSI)...just after a hard highway run, the first few times you come to a stop the lamp may flicker at idle - that's normal, give it a little gas to increase the fan speed until the residual heat has dissipated.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Engine/Oil Help

Do verify the hot oil pressure before anything---there is a better than even chance you are chasing ghosts.

If you do go 20W50 on a new engine, do NOT use Castrol GTX.

Do a little research on oils, most off the shelf oils are not flat tappet lifter compatible.

There are looooong threads on the subject here and most other places where gearheads gather.

(might be fine on a stocker, might not, why risk it?)

There are excellent, common oils that are OK you can buy pretty much anywhere, but using the wrong ones (most of them) could be fatal to your engine. Shell Rotella SAE30 or SAE40 have plenty of ZDDP and will still probably be SAE30 or 40 when you go to change them, rather than ~SAE20 after a couple Kmiles like cheaper multigrade oils tend to do.

Wally World sells Shell Rotella oils...Strangely, many Shell stations do not, which I find... weird.

There are many other good choices, but far outnumbered by bad ones.

You also might consider remote mounting that dual sender (if you keep it) on a rubber grease fitting flex hose or similar.

The weight of the dual sender tends to beat out the threads in a mag block pretty quickly.

If you do go 20W50 on a new engine, do NOT use Castrol GTX.

Do a little research on oils, most off the shelf oils are not flat tappet lifter compatible.

There are looooong threads on the subject here and most other places where gearheads gather.

(might be fine on a stocker, might not, why risk it?)

There are excellent, common oils that are OK you can buy pretty much anywhere, but using the wrong ones (most of them) could be fatal to your engine. Shell Rotella SAE30 or SAE40 have plenty of ZDDP and will still probably be SAE30 or 40 when you go to change them, rather than ~SAE20 after a couple Kmiles like cheaper multigrade oils tend to do.

Wally World sells Shell Rotella oils...Strangely, many Shell stations do not, which I find... weird.

There are many other good choices, but far outnumbered by bad ones.

You also might consider remote mounting that dual sender (if you keep it) on a rubber grease fitting flex hose or similar.

The weight of the dual sender tends to beat out the threads in a mag block pretty quickly.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

cvbug

- Posts: 14

- Joined: Wed Sep 12, 2012 12:14 pm

Re: Engine/Oil Help

I haven't done the oil change yet. I will continue to look and types and viscosities. But today i did take it again for a nice long drive on the freeway and around town and it started to every once in awhile do a little burp of blue smoke and it would start to stutter a bit and then clear right up and run fine. I got it home and did the dipstick test again and still cool to the touch, infact the intake just below the carb was ice cold with condinsation running down it. Is the normal? I have never expierienced that. Like mention above there are ghost or gremlins at work here.

Does any one know a a good bug mechanic in chula vista orsan diego ca i could take it too?

Does any one know a a good bug mechanic in chula vista orsan diego ca i could take it too?

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Engine/Oil Help

It's normal for the intake manifold to be cool - in cold/damp weather it may even be covered with frost. It's due to the "latent heat of vaporization", the same principle that refrigerators and air conditioners rely upon and the reason those compressed-air cans you use to blow off your computer keyboard get cold to the touch in use.

In order to keep the manifold's interior walls warm enough to prevent fuel from condensing on them, some exhaust is piped up along the bottom of the manifold to heat it. Stock mufflers are designed so the "heat riser" is plumbed in between two points with a pressure differential between them so there's a positive flow of exhaust through it. With almost no exceptions, aftermarket mufflers and header systems just have flanges on #2 & 4 exhaust, two points with nearly identical average pressure, so there's no real flow; the heat riser pipe still gets warm, but more through convection and sometimes it's just not enough to keep up with the chilling going on in the intake. Many headers don't even have the passages drilled out (makes them ready to go with dual carbs, no need to cap the flanges off) or the passages may be very small - you need to drill them out as big as you can go without hitting daylight.

And then there's the very real possibility that your manifold's heat riser passage is all coked up with years' accumulation of carbon, which can be a real bear to clear. There are a few methods that may clear it, the one most often used is to "Roto-Rooter" it out with a length of old clutch cable in a drill. viewtopic.php?f=18&t=121186

The problem gets worse when the intake manifold is bigger - larger tubes mean less velocity for a given RPM/displacement, putting conditions inside the manifold closer to the "dew point" where fuel will condense on the walls leaving you with a lean condition (plus big droplets dribbling into the chambers which are too large to burn properly). I used to have a baja with a big Holley BugSpray 2-bbl on it and the preheat system was a hopelessly inadequate - on cool/damp Seattle days I could only make it a few miles on the freeway before so much ice would form in the carb venturii that I'd lose all power and have to coast to the side of the road and wait for it to thaw (I carried a propane torch and a fire extinguisher for use when I didn't have time to wait). Ended up cutting the preheat pipe apart and welding sheetmetal pieces all around the center of the intake manifold to form a big chamber for the exhaust to collect so it could warm the manifold better.

If you get rid of that pretty aftermarket aircleaner and go back to a stock one, it'll have a provision for drawing warmed air coming off of the cylinder head - that helps too. Over the years there've been several ways to control the inlet temperature. On your `68, there was originally an external lever coming off of the RH thermostat flaps in the shroud that connected to a flap in the aircleaner via a Bowden cable. That setup worked (provided you had a functional thermostat) until the first time some moron yanked the aircleaner off without disconnecting the cable...there are very few unstretched cables still in existence. Later cars used manifold vacuum to operate a servo linked to the flap - also a good setup when new, but more things can go wrong. The BEST solution is the c1971 aircleaner which has its own integrated wax-pill thermostat to operate the flap...try to find one of those. They're easy to identify, the thermostat and its mechanism are right there on the outside of the inlet snorkel.

In order to keep the manifold's interior walls warm enough to prevent fuel from condensing on them, some exhaust is piped up along the bottom of the manifold to heat it. Stock mufflers are designed so the "heat riser" is plumbed in between two points with a pressure differential between them so there's a positive flow of exhaust through it. With almost no exceptions, aftermarket mufflers and header systems just have flanges on #2 & 4 exhaust, two points with nearly identical average pressure, so there's no real flow; the heat riser pipe still gets warm, but more through convection and sometimes it's just not enough to keep up with the chilling going on in the intake. Many headers don't even have the passages drilled out (makes them ready to go with dual carbs, no need to cap the flanges off) or the passages may be very small - you need to drill them out as big as you can go without hitting daylight.

And then there's the very real possibility that your manifold's heat riser passage is all coked up with years' accumulation of carbon, which can be a real bear to clear. There are a few methods that may clear it, the one most often used is to "Roto-Rooter" it out with a length of old clutch cable in a drill. viewtopic.php?f=18&t=121186

The problem gets worse when the intake manifold is bigger - larger tubes mean less velocity for a given RPM/displacement, putting conditions inside the manifold closer to the "dew point" where fuel will condense on the walls leaving you with a lean condition (plus big droplets dribbling into the chambers which are too large to burn properly). I used to have a baja with a big Holley BugSpray 2-bbl on it and the preheat system was a hopelessly inadequate - on cool/damp Seattle days I could only make it a few miles on the freeway before so much ice would form in the carb venturii that I'd lose all power and have to coast to the side of the road and wait for it to thaw (I carried a propane torch and a fire extinguisher for use when I didn't have time to wait). Ended up cutting the preheat pipe apart and welding sheetmetal pieces all around the center of the intake manifold to form a big chamber for the exhaust to collect so it could warm the manifold better.

If you get rid of that pretty aftermarket aircleaner and go back to a stock one, it'll have a provision for drawing warmed air coming off of the cylinder head - that helps too. Over the years there've been several ways to control the inlet temperature. On your `68, there was originally an external lever coming off of the RH thermostat flaps in the shroud that connected to a flap in the aircleaner via a Bowden cable. That setup worked (provided you had a functional thermostat) until the first time some moron yanked the aircleaner off without disconnecting the cable...there are very few unstretched cables still in existence. Later cars used manifold vacuum to operate a servo linked to the flap - also a good setup when new, but more things can go wrong. The BEST solution is the c1971 aircleaner which has its own integrated wax-pill thermostat to operate the flap...try to find one of those. They're easy to identify, the thermostat and its mechanism are right there on the outside of the inlet snorkel.

-

cvbug

- Posts: 14

- Joined: Wed Sep 12, 2012 12:14 pm

Re: Engine/Oil Help

Marc

Thank you for a very informitive write up. I did the roto-rooter thing to the intake riser but did not know I needed to drill the exhaust header. Now my question is will the gaskets on the intake be good if I loosen them up to drill the headers and retighten or will I need new gaskets? I would like to have every thing reading when i do this. All these little things are what the car was designed with and obvious wants back so I'll start listning to the car more.

Thank you for a very informitive write up. I did the roto-rooter thing to the intake riser but did not know I needed to drill the exhaust header. Now my question is will the gaskets on the intake be good if I loosen them up to drill the headers and retighten or will I need new gaskets? I would like to have every thing reading when i do this. All these little things are what the car was designed with and obvious wants back so I'll start listning to the car more.