914 FI and turbo

- dstar5000

- Posts: 4555

- Joined: Tue Feb 12, 2002 12:01 am

Re: 914 FI and turbo

What are you doing for a turbo?

I have a Subaru WRX STi, TD04L available that would

probably put you in the 250-280HP range, on a totally stock 2.0L.

Look at Wally's thread....

Don

I have a Subaru WRX STi, TD04L available that would

probably put you in the 250-280HP range, on a totally stock 2.0L.

Look at Wally's thread....

Don

-

romandian

- Posts: 5

- Joined: Thu Nov 19, 2009 10:09 am

Re: 914 FI and turbo

hi

throtle body with secondary shaft sounds interesting. how does this work. do you know any other tbs like that, that are bigger?

roman

throtle body with secondary shaft sounds interesting. how does this work. do you know any other tbs like that, that are bigger?

roman

- tango

- Posts: 49

- Joined: Tue Mar 31, 2009 12:45 pm

Re: 914 FI and turbo

Some news!

After illness, snow and ice I have ventured out to the still cold garage intent on getting running this summer.

Dstar, Thanks for the offer - I have a GT28R and GT2556 on the shelf at the moment, the GT28R is the plan but there may be some swapping around later.

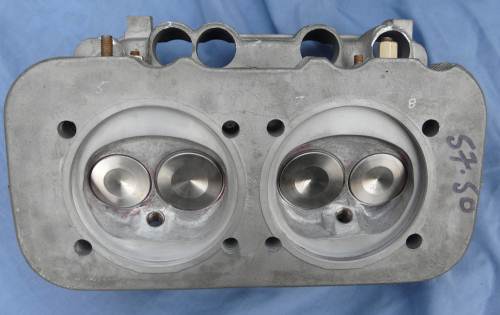

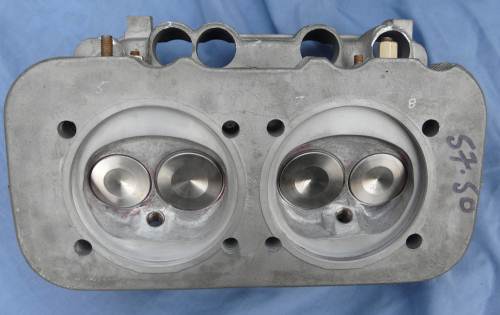

Heads have come and gone and finally arrived again, here they are, 75 2.0 heads, 12mm plugs, 44x40, dual springs, Ti retainers.

I ended up with the tool steel Thorsten Piper lifters and it turned out one of the flat topped 94mm pistons was cracked. So I put in a newer set of dished 94s with no gaskets and 0.9mm deck - should squeeze out I think 7.5:1 static CR which is lower than I would have liked, I was aiming around 8:1. Keeping an eye out for something but I aim to get running with the dished 94s, they actually look stronger. I almost went for some Oettinger 98 cyls but I discovered they are way too thin for boost.

Header and stubs not quite finished, gas tight but I want to do the final fit and set up on the final engine which I can now.

Here are some pics of the stubs bolted up with the header placed on.

I now think I will need a 228mm flywheel (I think its WasserB for forged, not sure) and PP - not sure on the PP and disk - I would like to retain street drivability.

Also I need some of the better retaining studs for the rockers, any ideas on vendors?

Also intercooling.. Volvo IC sounds simpler and potentially effective but inconvenient possibly (fixed over the engine bay somehow I guess? with the lid closing down on perhaps a foam seal to the IC? - perhaps some sort of quick release clamps to remove the IC would work).

Chargecooling - Then where to place the cooling rad - I have been thinking around the small 125cc motorcycle rads mounted in the front arches, with fans and shields..

Some progress, I now have to do some other work for a few weeks.

After illness, snow and ice I have ventured out to the still cold garage intent on getting running this summer.

Dstar, Thanks for the offer - I have a GT28R and GT2556 on the shelf at the moment, the GT28R is the plan but there may be some swapping around later.

Heads have come and gone and finally arrived again, here they are, 75 2.0 heads, 12mm plugs, 44x40, dual springs, Ti retainers.

I ended up with the tool steel Thorsten Piper lifters and it turned out one of the flat topped 94mm pistons was cracked. So I put in a newer set of dished 94s with no gaskets and 0.9mm deck - should squeeze out I think 7.5:1 static CR which is lower than I would have liked, I was aiming around 8:1. Keeping an eye out for something but I aim to get running with the dished 94s, they actually look stronger. I almost went for some Oettinger 98 cyls but I discovered they are way too thin for boost.

Header and stubs not quite finished, gas tight but I want to do the final fit and set up on the final engine which I can now.

Here are some pics of the stubs bolted up with the header placed on.

I now think I will need a 228mm flywheel (I think its WasserB for forged, not sure) and PP - not sure on the PP and disk - I would like to retain street drivability.

Also I need some of the better retaining studs for the rockers, any ideas on vendors?

Also intercooling.. Volvo IC sounds simpler and potentially effective but inconvenient possibly (fixed over the engine bay somehow I guess? with the lid closing down on perhaps a foam seal to the IC? - perhaps some sort of quick release clamps to remove the IC would work).

Chargecooling - Then where to place the cooling rad - I have been thinking around the small 125cc motorcycle rads mounted in the front arches, with fans and shields..

Some progress, I now have to do some other work for a few weeks.

_________________________

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

- tango

- Posts: 49

- Joined: Tue Mar 31, 2009 12:45 pm

Re: 914 FI and turbo

Little update.

Engine now together with heads and valve geo done. Added a 228mm flywheel and stock clutch to get going.

The header and stubs are gas tight and I have a muffler and mount onto the gearbox.

Thinking about intake plumbing and wiring. I have a huge chargecooler from ebay I could modify, maybe another that might be better sized. Probably putting chargecooler rad in the front where the oil cooler goes on a GT.

Need to get it running!

Engine now together with heads and valve geo done. Added a 228mm flywheel and stock clutch to get going.

The header and stubs are gas tight and I have a muffler and mount onto the gearbox.

Thinking about intake plumbing and wiring. I have a huge chargecooler from ebay I could modify, maybe another that might be better sized. Probably putting chargecooler rad in the front where the oil cooler goes on a GT.

Need to get it running!

_________________________

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: 914 FI and turbo

Droolworthy!!!

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- tango

- Posts: 49

- Joined: Tue Mar 31, 2009 12:45 pm

Re: 914 FI and turbo

Now running!

With basic tune in MS. Being careful with boost, AF and timing. Innovate LC1 just died completely so I cant tune till I get that replaced. I am thinking of other options since it let me down after only a little use although I have had it for a couple of years.

The set of injectors I was planning to use were no good, one stuck partly open so I am running on some very small, I think 200cc/19.5lb that I had. I need much bigger I think. Idle currently is 5.3ms and ~90% duty at 4000rpm with ~7psi at ~12AFR.

Here is a snapshot of a log, third and fourth up to the overboost protection cutting in at 7.5psi

With basic tune in MS. Being careful with boost, AF and timing. Innovate LC1 just died completely so I cant tune till I get that replaced. I am thinking of other options since it let me down after only a little use although I have had it for a couple of years.

The set of injectors I was planning to use were no good, one stuck partly open so I am running on some very small, I think 200cc/19.5lb that I had. I need much bigger I think. Idle currently is 5.3ms and ~90% duty at 4000rpm with ~7psi at ~12AFR.

Here is a snapshot of a log, third and fourth up to the overboost protection cutting in at 7.5psi

- Chip Birks

- Posts: 4006

- Joined: Wed Mar 12, 2008 5:59 pm

Re: 914 FI and turbo

I noticed in your signature that you are running sequential. How are you triggering off of the cam in order to get that signal for the sequential? Your setup looks AWESOME! My little bro has a 914 and is building a new motor for it, with the potential to go turbo in the future. I need to direct him to this thread. Get some way bigger injectors in there. Don't want to blow it up. Also, regarding the LC-1, they can cause some major headaches for sure. I know that Innovate has done some redesigning of the LC-1 within the last 3 years or so. Might be worth it to give them another chance. Unless of course someone knows of a better system out there.

- tango

- Posts: 49

- Joined: Tue Mar 31, 2009 12:45 pm

Re: 914 FI and turbo

It is a LOAD of fun so far, the 914 is meant for this kind of performance! It still needs a lot of sorting and tidying but now running smooth and leak free, loving MS tuning. I feel a growing need for knock sensing.. just how far can I go with 7.5 static, prob only 6.5 dynamic? Thinking about fixing up some headphones to listen for knock until a J and S or something comes my way.

Siemens Deka injectors should be here soon, they should be better, certainly a lot bigger at 600cc. Quality injectors get expensive but I think worth it.

My LC1 was around 18months old and only run for perhaps 30 hours, perhaps I was just unfortunate. I have just got a Tech Edge 2J2 to replace it from Trigger-wheels.com. Its their new model to replace the 2J1, it has built in cal button and LED and terminals and connectors rather than potted in cables.

I started out trying to get it going with batch fire but in the end it was easier to go straight to sequential since I could tell which plug and injector should fire and when.

I looked at fitting a Hall sensor into the case to pickup from a bolt on the cam as I have seen done on a T1 case (not sure if that is on this forum) but using a Pertronix with only one magnet in the dizzy was much simpler.. but I fried that (this was preferable to frying the MS..) and ended up grinding 3 lobes off the dizzy and using points! I connected that via the opto CCT on the MS and used the VR CCT for crank. You can just see the dizzy in this pic.

Siemens Deka injectors should be here soon, they should be better, certainly a lot bigger at 600cc. Quality injectors get expensive but I think worth it.

My LC1 was around 18months old and only run for perhaps 30 hours, perhaps I was just unfortunate. I have just got a Tech Edge 2J2 to replace it from Trigger-wheels.com. Its their new model to replace the 2J1, it has built in cal button and LED and terminals and connectors rather than potted in cables.

I started out trying to get it going with batch fire but in the end it was easier to go straight to sequential since I could tell which plug and injector should fire and when.

I looked at fitting a Hall sensor into the case to pickup from a bolt on the cam as I have seen done on a T1 case (not sure if that is on this forum) but using a Pertronix with only one magnet in the dizzy was much simpler.. but I fried that (this was preferable to frying the MS..) and ended up grinding 3 lobes off the dizzy and using points! I connected that via the opto CCT on the MS and used the VR CCT for crank. You can just see the dizzy in this pic.

_________________________

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

- CobraJet

- Posts: 430

- Joined: Sun Oct 31, 2010 11:12 pm

Re: 914 FI and turbo

How is it running now, did you get a good tune on it with the new injectors?

- tango

- Posts: 49

- Joined: Tue Mar 31, 2009 12:45 pm

Re: 914 FI and turbo

Update!

Not a lot really.

Got hold of some Boxster wheels, 16x6 and 16x7, 225 55 to help with traction. Much better. Also new rear shocks - relief to my spine compared to the KYBs!

Managed to mess up the maps when I switched the injectors and spent a while getting it back.

Really not liking the low CR rpm characteristic before boost but I have a solution, got some JE forged pistons to go in :-

Also fitted the MS electronic boost control solenoid great! closed loop, RPM/TPS/boost map! instant boost!.. but .. whilst I was debugging that the motor started to make some unwelcome noises so I have not had any real driving on it. The noise is an intermittent clacking, it comes and goes and got worse until I decided to leave it, maybe cam bolts backing out? Drained the oil an it is silvery, maybe a cam bearing/cam thrust? Dunno.

So I am going to strip it down and see, maybe next week, good to check up and catch anything before catastrophic disaster. Then reassemble with the new pistons and maybe new barrels if they are bad (EMW probly?) thought about cutting sealing rings into the heads/barrels but I am not sure it is necessary until above 15psi, especially with 94mm.

Clutch has slipped a little occasionally so I think a Kennedy stage 2 I think with a stock disc should do? (as much as the 901 will handle). There is a Sachs HD 228mm but I am not sure what holding torque that would give, I think only another 30% at best?

Also thinking about moving the oil cooler up front 914/6 GT style, with a chargecooler rad mounted in front, oil pipes one side of the car, water pipes the other. Probably some better/track brake pads too.

Could do with some heat too..

Not a lot really.

Got hold of some Boxster wheels, 16x6 and 16x7, 225 55 to help with traction. Much better. Also new rear shocks - relief to my spine compared to the KYBs!

Managed to mess up the maps when I switched the injectors and spent a while getting it back.

Really not liking the low CR rpm characteristic before boost but I have a solution, got some JE forged pistons to go in :-

Also fitted the MS electronic boost control solenoid great! closed loop, RPM/TPS/boost map! instant boost!.. but .. whilst I was debugging that the motor started to make some unwelcome noises so I have not had any real driving on it. The noise is an intermittent clacking, it comes and goes and got worse until I decided to leave it, maybe cam bolts backing out? Drained the oil an it is silvery, maybe a cam bearing/cam thrust? Dunno.

So I am going to strip it down and see, maybe next week, good to check up and catch anything before catastrophic disaster. Then reassemble with the new pistons and maybe new barrels if they are bad (EMW probly?) thought about cutting sealing rings into the heads/barrels but I am not sure it is necessary until above 15psi, especially with 94mm.

Clutch has slipped a little occasionally so I think a Kennedy stage 2 I think with a stock disc should do? (as much as the 901 will handle). There is a Sachs HD 228mm but I am not sure what holding torque that would give, I think only another 30% at best?

Also thinking about moving the oil cooler up front 914/6 GT style, with a chargecooler rad mounted in front, oil pipes one side of the car, water pipes the other. Probably some better/track brake pads too.

Could do with some heat too..

_________________________

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

- mlauzon

- Posts: 74

- Joined: Tue Sep 21, 2010 6:31 pm

Re: 914 FI and turbo

Tango,

VERY nice engine and I like your trick fuel rail and CNP brackets. Would you post some close up of these? I have a friend that may be able to fabricate them for me. Keep posting with your progress.

Some of my links

http://www.shoptalkforums.com/viewtopic ... 3&t=135228

http://www.shoptalkforums.com/viewtopic ... 3&t=134615

Thanks

VERY nice engine and I like your trick fuel rail and CNP brackets. Would you post some close up of these? I have a friend that may be able to fabricate them for me. Keep posting with your progress.

Some of my links

http://www.shoptalkforums.com/viewtopic ... 3&t=135228

http://www.shoptalkforums.com/viewtopic ... 3&t=134615

Thanks

Michel Lauzon

Working on a Type 4 Megasquirt Project

Working on a Type 4 Megasquirt Project

- tango

- Posts: 49

- Joined: Tue Mar 31, 2009 12:45 pm

Re: 914 FI and turbo

Hi,

The fuel rails were from an Audi 4 cyl, cut in half, welded and pressure tested, it was cheap and easy at the time. I think £5 off ebay. If I did it again I would would be very tempted to get some of the expensive extruded ali fuel rail, especially since I can now weld aluminium.

By the time I made the coil brackets I had got hold of AC TIG so they were one of my first attempts at welding ali, I would definitely use thicker ali if I did them again. I also had to weld nuts to the tinware to mount the brackets to.. That TIG welder - Thermal Dynamics 300GTSW AC TIG will soon be for sale once the service is complete since I no longer have access to 3 phase, excellent machine, 300A 3 phase. The good news is I now have a Thermal Dynamics 180 which works well.

I stripped the engine and all looks reasonably OK to me except I think some of the lifters have not been rotating properly in the bores so I need to look at the clearances but the cam seems OK. The cam end play is .1mm which I believe is a lot for a few thousand miles so I think new thrust bearings, it possibly started out a bit loose and the thrust surface is not too smooth, I will polish it a little. I thought I may be able to get the barrels honed to suit the new forged pistons since they require a looser fit but they are a bit scored so I am looking to get some new barrels honed to spec once I find somebody to supply them and do the honing properly.

Any events near Tampa in the next couple of weeks? I should be over for a few days.

The fuel rails were from an Audi 4 cyl, cut in half, welded and pressure tested, it was cheap and easy at the time. I think £5 off ebay. If I did it again I would would be very tempted to get some of the expensive extruded ali fuel rail, especially since I can now weld aluminium.

By the time I made the coil brackets I had got hold of AC TIG so they were one of my first attempts at welding ali, I would definitely use thicker ali if I did them again. I also had to weld nuts to the tinware to mount the brackets to.. That TIG welder - Thermal Dynamics 300GTSW AC TIG will soon be for sale once the service is complete since I no longer have access to 3 phase, excellent machine, 300A 3 phase. The good news is I now have a Thermal Dynamics 180 which works well.

I stripped the engine and all looks reasonably OK to me except I think some of the lifters have not been rotating properly in the bores so I need to look at the clearances but the cam seems OK. The cam end play is .1mm which I believe is a lot for a few thousand miles so I think new thrust bearings, it possibly started out a bit loose and the thrust surface is not too smooth, I will polish it a little. I thought I may be able to get the barrels honed to suit the new forged pistons since they require a looser fit but they are a bit scored so I am looking to get some new barrels honed to spec once I find somebody to supply them and do the honing properly.

Any events near Tampa in the next couple of weeks? I should be over for a few days.

_________________________

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: 914 FI and turbo

The cam/lifters look fine from what can be seen in the pics.

1mm cam play will make funny noises... that's what finally made me tear the Piles 1700 down after 400K++ miles.

.003-.004" is about right.

I have had to cut and polish new Webcams thrusts, as Web apparently forgets occasionally.

(OTOH I have a handy lathe)

Cast iron cam cores will probably have some porosity... don't make it too big trying to fix it, a few coats of 3M Moly-kote, dry/low temp bake, then polish...

Make sure that thrust is flat, correct dimensions, and highly polished as possible.

also make sure to use the dual thrust or Jakes HD cam thrust bearings.

I'm not sure if Jake in the only source for the T4 cam dual thrust bearings, IIRC ACN sells them, or you can make them yourself for the price of 2 sets of std cam bearings.

Jake has the HD thrust bearings made for his roller cam setups, thy are lap to fit, make sure the cam is the right size...(or a little bigger)

1mm cam play will make funny noises... that's what finally made me tear the Piles 1700 down after 400K++ miles.

.003-.004" is about right.

I have had to cut and polish new Webcams thrusts, as Web apparently forgets occasionally.

(OTOH I have a handy lathe)

Cast iron cam cores will probably have some porosity... don't make it too big trying to fix it, a few coats of 3M Moly-kote, dry/low temp bake, then polish...

Make sure that thrust is flat, correct dimensions, and highly polished as possible.

also make sure to use the dual thrust or Jakes HD cam thrust bearings.

I'm not sure if Jake in the only source for the T4 cam dual thrust bearings, IIRC ACN sells them, or you can make them yourself for the price of 2 sets of std cam bearings.

Jake has the HD thrust bearings made for his roller cam setups, thy are lap to fit, make sure the cam is the right size...(or a little bigger)

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- tango

- Posts: 49

- Joined: Tue Mar 31, 2009 12:45 pm

Re: 914 FI and turbo

Update!! It's off the stands again!

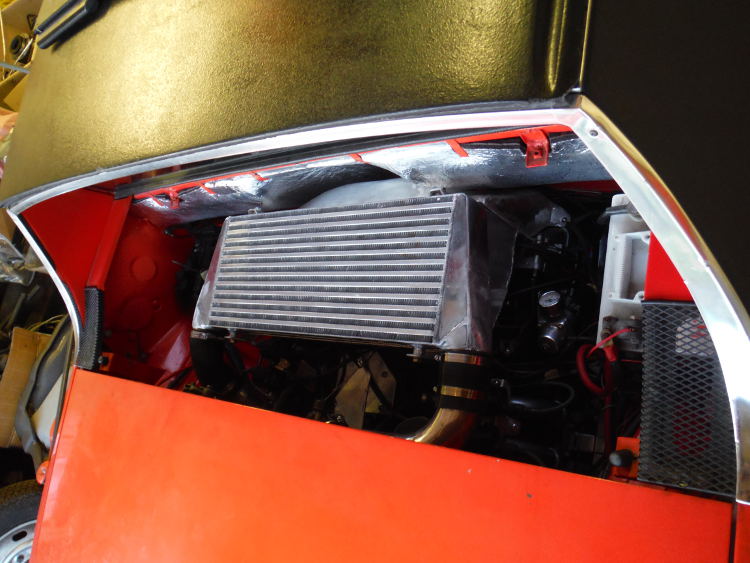

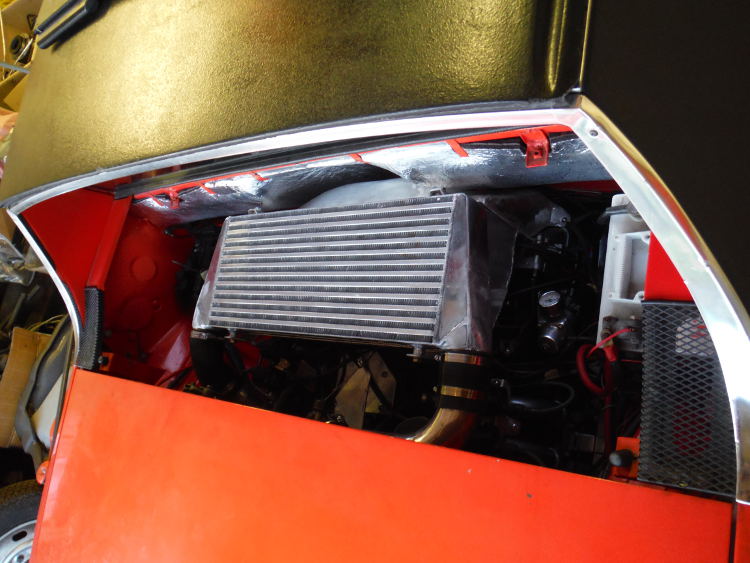

A few years on and a bit of a refresh. I never hooked up the water IC, couldn't be fussed with the water/pipes/potential hacking of the car so I am trying out an air-air IC. Still not switched to the MS3 yet, I wanted to use the known running tune of the old MS2 to break in the engine refresh.

Milder cam (C25), slightly lower CR, but mostly refresh the heads that were a bit toasted and causing bad leak down figs. Lots of corrections of on the job temporary fixes. And a large IC on top of the engine ducted to the cooling fan(Piledriver mentioned something like this and I looked at 911 turbos), and relocated the TB. see pics.

Not much running so far, tunerstudio seems to like it on autotune, definitely better though boost seems to be out of control at the moment, hitting the safety cut. Idle is a disappointing 80ish KPA although reliable. Tuning to be done.

Anyone experience of the c25/MS etc. I'll try to post some Logs etc.

A few years on and a bit of a refresh. I never hooked up the water IC, couldn't be fussed with the water/pipes/potential hacking of the car so I am trying out an air-air IC. Still not switched to the MS3 yet, I wanted to use the known running tune of the old MS2 to break in the engine refresh.

Milder cam (C25), slightly lower CR, but mostly refresh the heads that were a bit toasted and causing bad leak down figs. Lots of corrections of on the job temporary fixes. And a large IC on top of the engine ducted to the cooling fan(Piledriver mentioned something like this and I looked at 911 turbos), and relocated the TB. see pics.

Not much running so far, tunerstudio seems to like it on autotune, definitely better though boost seems to be out of control at the moment, hitting the safety cut. Idle is a disappointing 80ish KPA although reliable. Tuning to be done.

Anyone experience of the c25/MS etc. I'll try to post some Logs etc.

_________________________

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

1973 914 2.0 turbo undergoing a bit of a mech refresh (Running!)

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: 914 FI and turbo

Have only used a C25 NA but it seems to me it would be a perfect turbo cam.

Those popup JEs provide what compression ratio?

Did you machine flat?

Looks like an excellent setup, how many miles did you manage?

Those popup JEs provide what compression ratio?

Did you machine flat?

Looks like an excellent setup, how many miles did you manage?

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.