A few months back I posted a question on TB size, and I got some great advice.

In the meantime, my engine plans have changed slightly, and I need advice as to whether I am heading in the right direction...

My current engine is an 1835cc with 69mm counterwighted crank, a w110 cam, heads with 37x42 valves, and generally overhauled and blueprinted.

It currently has a pair of Dellorto 40mm on it, but looking at the state of the car it will go into, it will probably not be runnig this side of Easter (07)...

So, since I am assembling a MS II V3.0 kit during the long, cold nights up here in Norway, I may convert this 1835 engine to FI before I put it into the car in time for summer (My original plan was to use the engine as is, and build a new 2174 engine where the FI would go).

For the HW for the FI system, I plan as follows:

- MS II v3.0, also controlling ignition

- single TB

- CB or similar end castings

- plenum located under/behind original/modified generator stand

- VW wbx distributor incl. hall sensor

- various TPS and temp sensors

- narrow band O2 sensor

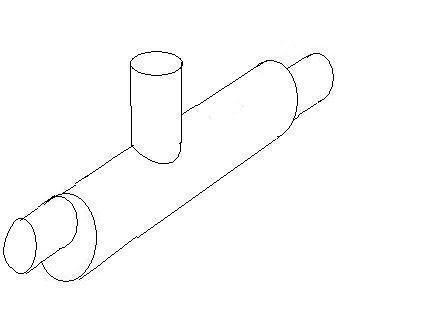

I am planning a plenum design along the line of this:

(Forgive me for borrowing your drawing, Mabbo)

My targets for the project are:

- To understand and get to know the MS system

- To learn how to tune the MS properly before letting myslef loose on a REALLY expensive engine

- Equal or better performance than the dell's

- Better driveability than the dell's

Now to my questions:

1

What guidelines exist for designing plenum and runner lengths

2

What TB size would suit (I have a 45mm from a wbx lying around)

3

Will I achieve my targets?

Any feedback is highly appreciated on this matter