Current configuration if anyone cares:

78mm crank

90.5mm bore

Gene Berg 309 camshaft

Steve Tims Stage 1 heads

Dual Weber 42 DCNF

Bosch 019 centrifugal advance distributor

Here's the stuff from the junkyard.

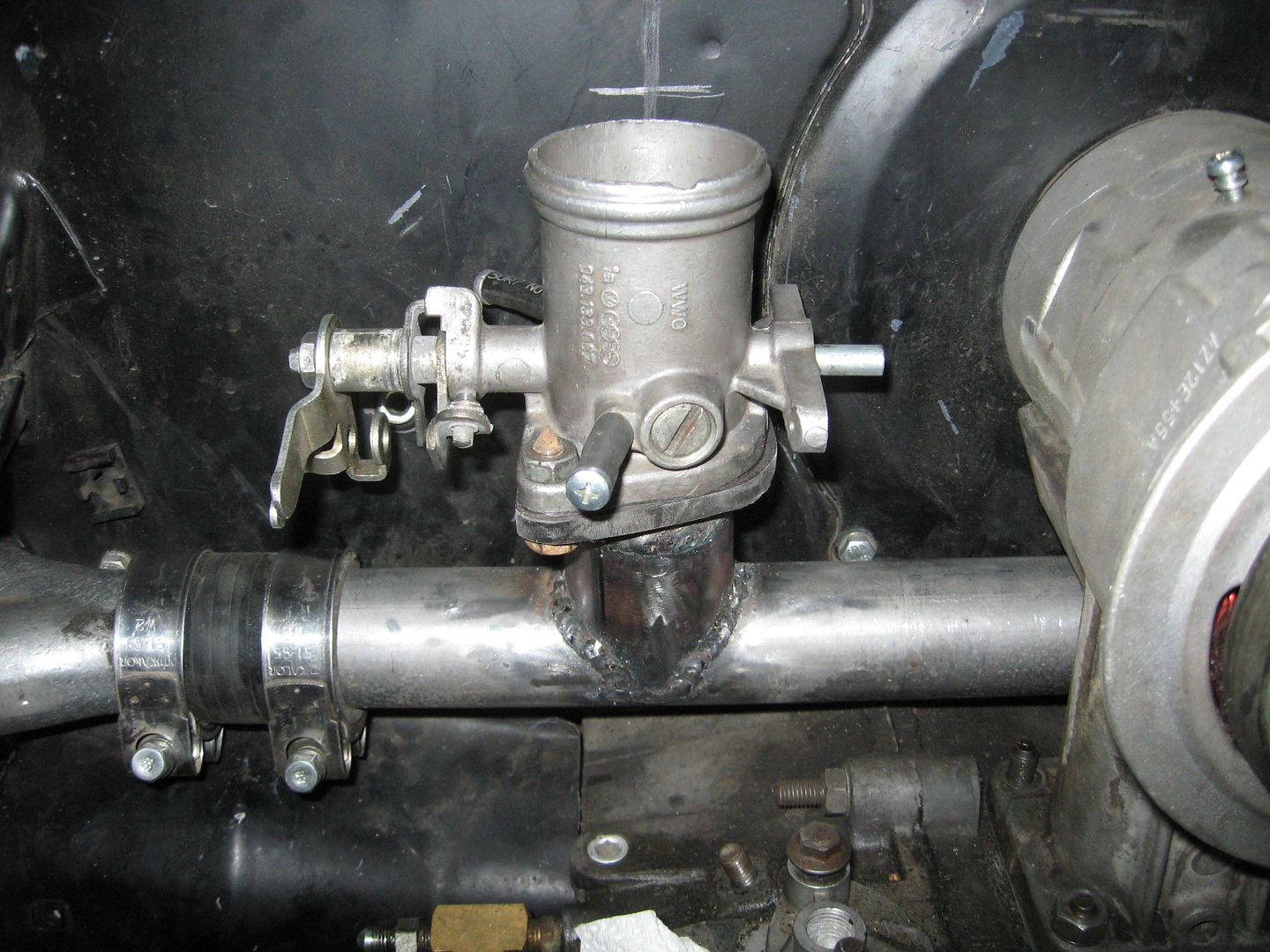

Throttle body from Mercury Mystique, I measured the throttle plate at 58mm. Fuel injectors from a Ford Festiva. MAP sensor from a 3.8L GM sedan and ignition coils from a Chevrolet pickup truck. I forgot to get an IAT sensor, coolant sensor, and fuel pump. Oops.

The injectors are probably the only regret here, looking up the part number they are only 15 lb/hour. I estimate my junk to make 100HP at most, that may be generous. From the online calculators I've used they should be just enough.

I'm going to go with thedubshop's hidden trigger wheel/sensor and a Megasquirt of some type. I'm leaning toward microsquirt at this time but the MS3 doesn't cost too much more...

I having been trying to learn some CAD and drew the intake.

I'm sure the dimensions are not correct. For example the lower tubes that couple to the end castings, I don't have any end castings so I don't know what diameter those should be. I am hoping to mount the throttle body in a similar location to a stock carburetor. As such the offset from the alternator hasn't been taken into account.

Progress will be slow. It took me forever to build the motor and get it running reasonably, so maybe I'll be done before 2020.

Questions? Comments? Criticisms? Suggestions?