The following is a bunch of pictures and discussion on why I am probably going one way although I am only luke warm about it. I talked to several people about it including one machinist and a couple of other VW guys. I did get one suggestion to convert to a Geo Metro rack and pinion which is pretty much a bolt in job according to the the VW guy who has done it. Maybe later on.

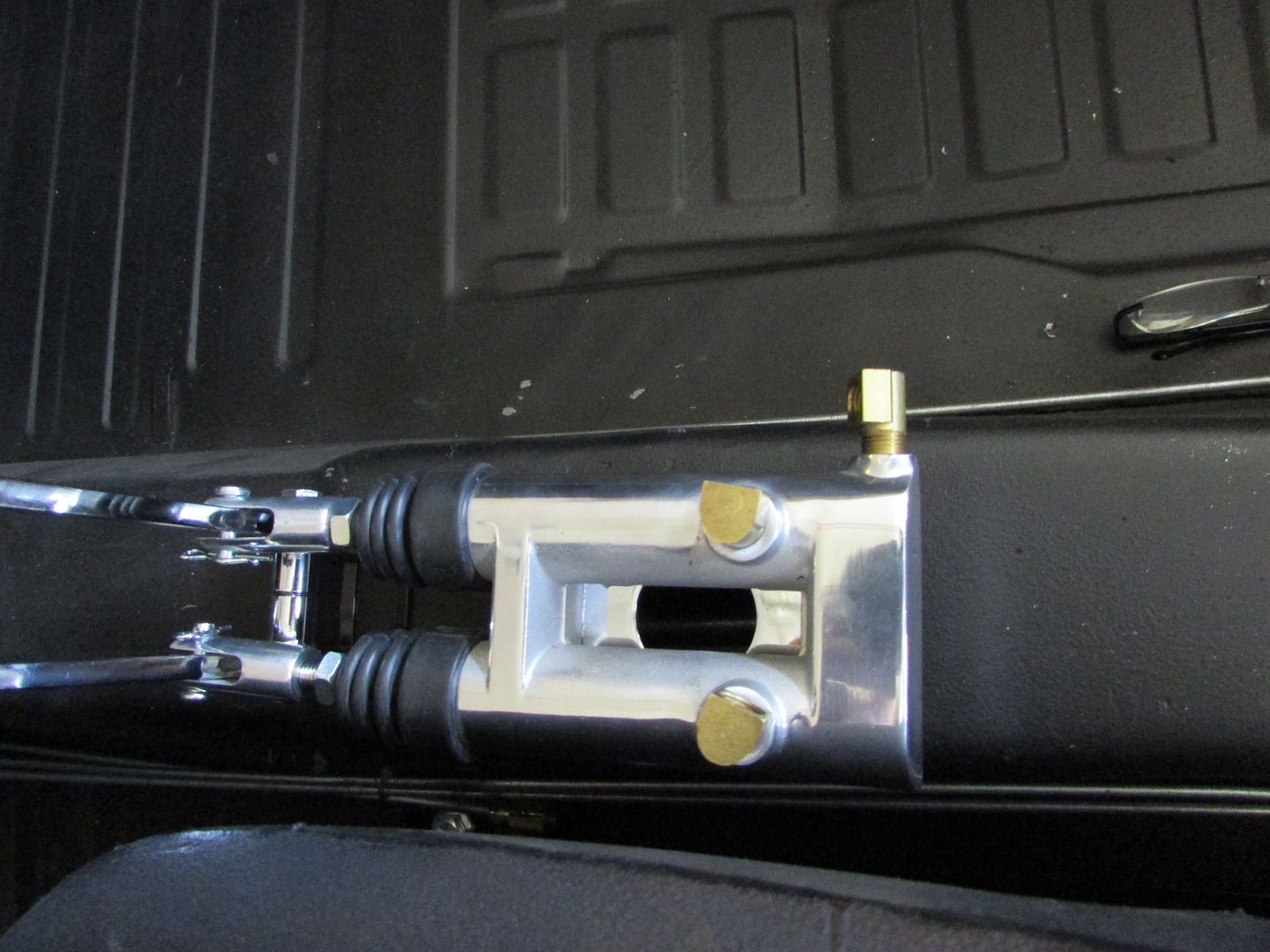

This is the steering box I am using. It seems to be in good shape and the worm and selectors seem to be nice and tight. By the part number it is a type 3 steering box and yes I do have the matching Pittman Arm. After a lot of counting… by several different people the spline count seems to be 48 splines.

The first suggestion I was given was to use the stock VW rag join but because of the angle tightness of the situation the stock rag joint would not fit the situation. Rough dimensions that I am dealing with here are: From the beam to the fire wall is ~10” to 12”. The rough dimension from the inside of the fire wall to the bottom of the dash is~25”. The bottom of the dash to the floor is 22”. When sitting in the driver’s seat the distance from the dash to the front of the seat back ranges from 28 ½” to 34 ½”.

Based on the two people sitting at the farthest distance and very close to the foremost seating position holding on to the steering wheel at a comfortable location ranges from 3” to 3 ½” and the height of the steering shaft at the dash is 20 ½” to 22 ½”.

With the steering box in its normal position mounted on the beam the angle of the worm gear shaft is very steep and the rag joint would not allow the steep angle. It was suggested that the steering box be rotated some as on the sand the slippage is enough not to bother things too much but I do have some pavement to transverse so that suggestion was nixed pretty quick.

This is the chrome aftermarket version of the rag joint connector. It and the piece that goes into the steering column cost ~$20. Their spline count is again 48 splines. The part shown in the picture shows about where the fitting sits after some pushing and shoving; it should go clear to the end of the mount. The splines stop close to where the end of the split is (this is probably important).

This is the same fitting as the chrome one but came off one of the beams that Daron gave me. I do not feel as bad farting around with it as I would with the $$$ units.

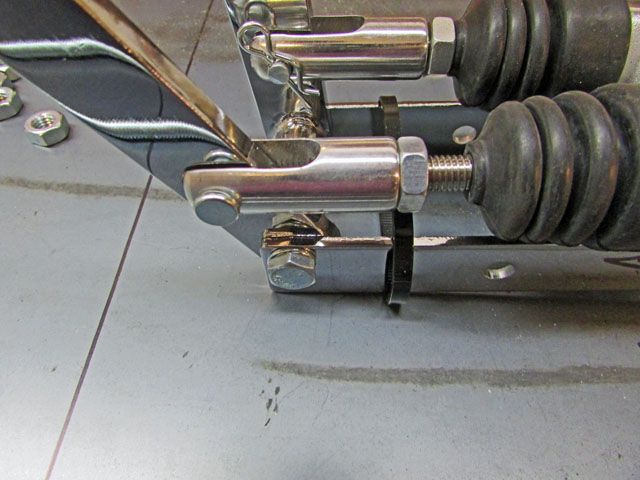

This is the second option we worked with. It is a universal that is splined on one end and a slip-in fit on the other end which is where the steering shaft attaches. It was available in 36 or 48 splines but the 48 spline is for a ¾” dia splined input (it is also available in smooth in some universals. The 36 spline unit does not match up to not only the spline count of the steering box but the shaft dia I will be using also.

Shaft diameter was based on the quick disconnect I got many years ago. Not knowing the difference back then I got the 7/8” rather than the ¾” or the 5/8” so everything must match up with the 7/8” steering coupler.

This shows the input splined area of the universal.

This is the adapter you can order that fits in the universal. This is the 2” version and I think there was a 6” or 8” version of it with the longer version not usable again because of the steering angle. Notice the grove around the splined area for the universal’s lock setup to slip into.

This is how it fits in the universal; it is a nice smooth fit.

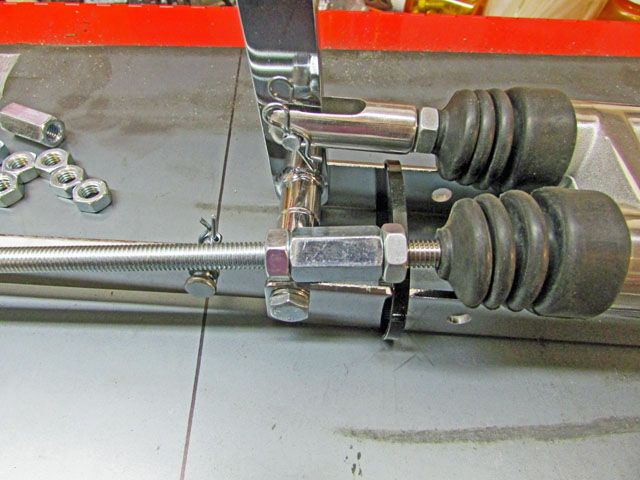

Now we are getting down to the tight jaw area for me. The suggested solution here was to machined off the splined area, bevel both the worm gear shaft and the adapter shaft then have the shafts welded together. One problem would be with the heat and the second problem(s) would be that there would need to be a sleeve over the joint and the worm shaft dia was slightly larger than the adapter shaft. The machinist would not do it for me mostly for liability reasons.

He did suggest that a machinist in the next town north of me spline the shaft but it would be expensive assuming they would even do it.

This is the last suggestion and while I don’t like it, it isn’t really much, if any, worse than VW used.

The rag joint end would have the adapter welded into the flanged end of the adapter (the flanges would be removed) after a thin adapter was made as the shaft diameter of the adapter and the mount are slightly different.

The splines of the worm gear shaft would have to be shortened so the hole in the adapter for the locking bolt would fit into the relief on the worm gear shaft. Doable… yes as long as I don’t do the welding. I think it need to be TIG welded to get penetration, not to get the heat up and to capture the adapter all in the one weld. I am also not sure that at least one plug weld would need to be done.

Lee