Camshaft grinds for turbo

-

shag55

- Posts: 1245

- Joined: Mon Nov 19, 2007 11:04 am

Re: Camshaft grinds for turbo

You can order from Pauter. That's a good cam.

------------------------------------

Shag Leone, SL-1 Racing

325WHP and 290TQ @17# on 91oct

383WHP and 324TQ @23psi on 50/50 mix

What's next?

Need a turbo or parts!

[email protected]

Facebook at SL 1 racing

Shag Leone, SL-1 Racing

325WHP and 290TQ @17# on 91oct

383WHP and 324TQ @23psi on 50/50 mix

What's next?

Need a turbo or parts!

[email protected]

Facebook at SL 1 racing

-

shag55

- Posts: 1245

- Joined: Mon Nov 19, 2007 11:04 am

Re: Camshaft grinds for turbo

What's your EVO on your new cam vs your old one. Going to the smaller turbine Would like less overlap and earlier opening for better spool yet keep exhaust pressure in check.

------------------------------------

Shag Leone, SL-1 Racing

325WHP and 290TQ @17# on 91oct

383WHP and 324TQ @23psi on 50/50 mix

What's next?

Need a turbo or parts!

[email protected]

Facebook at SL 1 racing

Shag Leone, SL-1 Racing

325WHP and 290TQ @17# on 91oct

383WHP and 324TQ @23psi on 50/50 mix

What's next?

Need a turbo or parts!

[email protected]

Facebook at SL 1 racing

- Wally

- Posts: 4563

- Joined: Mon Oct 28, 2002 12:01 am

Re: Camshaft grinds for turbo

Total valve overlap is 28 degrees for the FK7 and should be 40 with the Pauter cam

I don't think exhaust back pressure has much to do with the cam and much more with the turbine wheel size and shape and A/R of the turbine housing.

Remember, this is still on only 1208cc of an engine...

I don't think exhaust back pressure has much to do with the cam and much more with the turbine wheel size and shape and A/R of the turbine housing.

Remember, this is still on only 1208cc of an engine...

T4T: 2,4ltr Type 4 Turbo engine, 10.58 1/4 mi

www.apfelbeck.nl

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

www.apfelbeck.nl

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

-

Steve Arndt

- Posts: 7404

- Joined: Sat Mar 10, 2001 12:01 am

Re: Camshaft grinds for turbo

Are you going by the card data, or actual valve events? The three web cams I have degreed in haven't been close to what the cards depict. I'm currently using an 86A ground 115LC and retarded 2 degrees in my n/a engine. It feels like it would be a good street turbo cam. Very minimal overlap compared to the "B" I ran before, but still pulls quickly to 6500.

Steve

My Baja Build

My Baja Build

- Wally

- Posts: 4563

- Joined: Mon Oct 28, 2002 12:01 am

Re: Camshaft grinds for turbo

Bit difficult to go by the actual valve events if I haven't even got that cam yet huh?

Besides, it is beyond me tbh why anyone would want a 115LC cam in a N/A engine? You probably miss out a lot of torque mid range, but I am sure you had your reasons.

Besides, it is beyond me tbh why anyone would want a 115LC cam in a N/A engine? You probably miss out a lot of torque mid range, but I am sure you had your reasons.

-

SamT

- Posts: 28

- Joined: Sun Sep 23, 2012 9:57 am

Re: Camshaft grinds for turbo

I'm going with a FK44 in my 2332 blow through motor. Just a regular FK44, on 108 LSA.

Some where miniman said to "pick a cam you like N/a and you will love it turbo" So I added that to the add 1000RPM to the cam advertised RPM if you turbo.

SO I hope to get great bottom end, huge midrange, and still rev to 8000 MAX

Some where miniman said to "pick a cam you like N/a and you will love it turbo" So I added that to the add 1000RPM to the cam advertised RPM if you turbo.

SO I hope to get great bottom end, huge midrange, and still rev to 8000 MAX

-

Steve Arndt

- Posts: 7404

- Joined: Sat Mar 10, 2001 12:01 am

Re: Camshaft grinds for turbo

Lets see. I have an almost zero emission engine that puts out a ton of power and runs 12.2:1 compression on 91 pump gas. That is why I chose that cam timing.

Steve

My Baja Build

My Baja Build

-

shag55

- Posts: 1245

- Joined: Mon Nov 19, 2007 11:04 am

Re: Camshaft grinds for turbo

Sorry Wally, was referring to your 2 liter when you swapped cams.Wally wrote:Total valve overlap is 28 degrees for the FK7 and should be 40 with the Pauter cam

I don't think exhaust back pressure has much to do with the cam and much more with the turbine wheel size and shape and A/R of the turbine housing.

Remember, this is still on only 1208cc of an engine...

No the cam doesn't change the pressure much unless you close the valve early and hold back the charge which would not be good.

------------------------------------

Shag Leone, SL-1 Racing

325WHP and 290TQ @17# on 91oct

383WHP and 324TQ @23psi on 50/50 mix

What's next?

Need a turbo or parts!

[email protected]

Facebook at SL 1 racing

Shag Leone, SL-1 Racing

325WHP and 290TQ @17# on 91oct

383WHP and 324TQ @23psi on 50/50 mix

What's next?

Need a turbo or parts!

[email protected]

Facebook at SL 1 racing

- Wally

- Posts: 4563

- Joined: Mon Oct 28, 2002 12:01 am

Re: Camshaft grinds for turbo

I thought so Shag and I agree

- Type 4 Unleashed

- Moderator

- Posts: 2202

- Joined: Tue Nov 08, 2005 10:43 pm

Re: Camshaft grinds for turbo

Hi Wally, so how are you doing ?

You know this how ? Or are you just making an assumption ?Wally wrote: Besides, it is beyond me tbh why anyone would want a 115LC cam in a N/A engine? You probably miss out a lot of torque mid range, but I am sure you had your reasons.

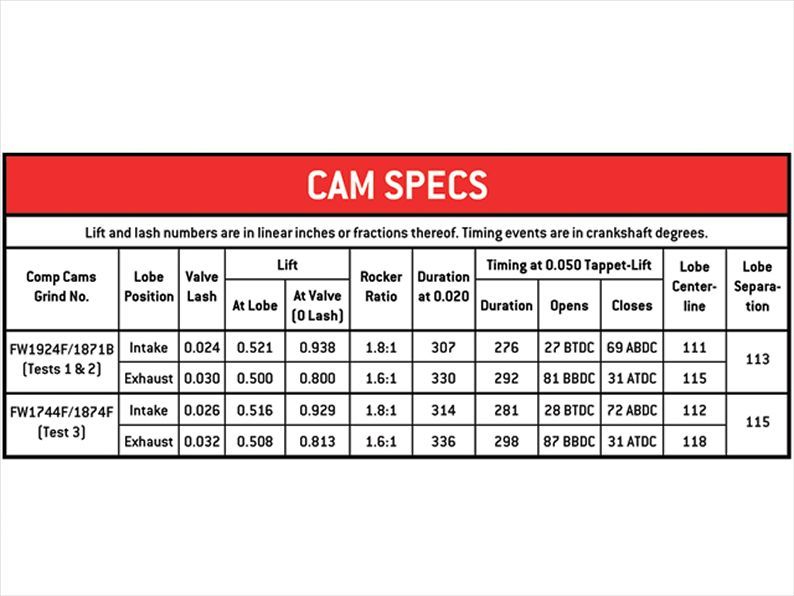

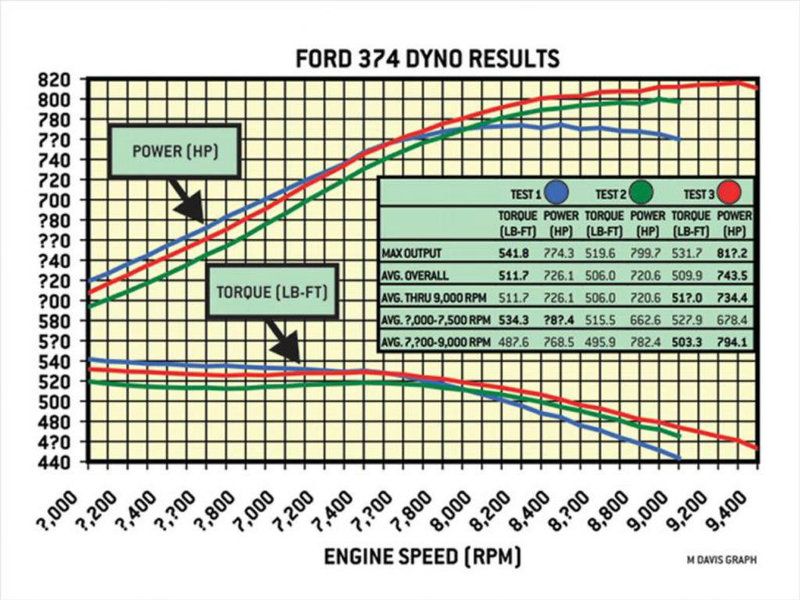

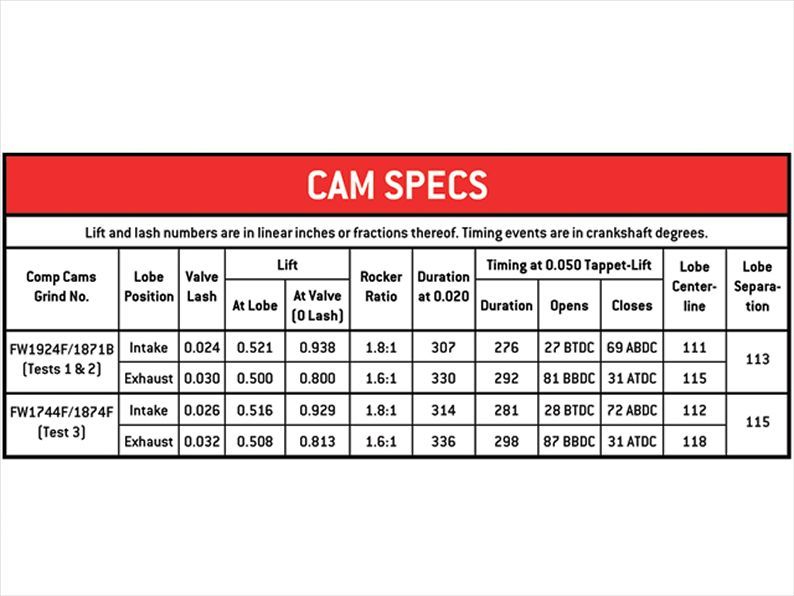

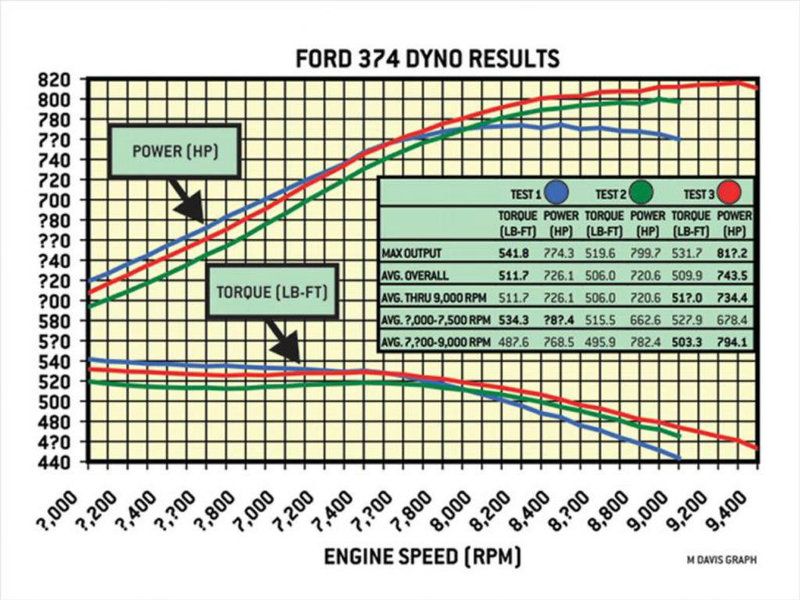

The cams durtation was increased, and normaly the overlap would increase and you loose Dynamic C/R for one but not if you spread the lobe centers. There is more to it then just the overlap & lobe seperation. So I thought I would point out why some one would and does use a 115LC on a N/A engine...In theory, Godbold says, "This engine is almost like a restrictor-plate engine, but it's restricted at the port instead of at the top of the intake plenum. We're making a lot of power per cfm, so we need to be more miserly with the air that does come in." In other words, the smaller the heads are in terms of flow and port volume compared with the engine's displacement, the more cam you need. But after a certain point, simply adding overlap doesn't necessarily improve airflow into the engine, especially at the extreme high rpm this engine must turn to generate the big power numbers. Instead, Comp spread the lobe separation, which allows more duration without correspondingly increasing the overlap

Richard

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

- Wally

- Posts: 4563

- Joined: Mon Oct 28, 2002 12:01 am

Re: Camshaft grinds for turbo

Nice V8 graphs Richard  but that doesn;t mean much to me unfortunately; I like to keep this complex subject a little closer to my chest: from my own personal experience with two similar cams on the same (mine) engine, the milder one but with the 114LC wasn't that impressive mid-range. For turbo (on topic) great to reduce mid-range torque so you save clutch and gearboxes and keep the torque longer up top (more max hp). But the really low dynamic CR had its negatives as well and those outshined the benefits for me.

but that doesn;t mean much to me unfortunately; I like to keep this complex subject a little closer to my chest: from my own personal experience with two similar cams on the same (mine) engine, the milder one but with the 114LC wasn't that impressive mid-range. For turbo (on topic) great to reduce mid-range torque so you save clutch and gearboxes and keep the torque longer up top (more max hp). But the really low dynamic CR had its negatives as well and those outshined the benefits for me.

In short:I liked the smaller LC with more duration better and I think with the 'assymetrical' valve timing (as I call it), I think you can regain some of the high end hp while still retaining high mid-range torque from a small LC cam. Thats what I expect the Pauter cam(s) to do.

Besides, all all N/A cams of JPM are now ground on even smaller LC's (106).

[edit]: Come to think of it, I can understand the use of larger LC's if you have a big dome on the intake side of the piston ie squishy pistons: larger LC retards the intake valve timing: later opening and later closing of the intake valve. Like you said correctly, later closing gives a lower dynamic CR (for me this usually means less max torque) while keeping duration. For me thats a huge negative, but for some who can use only shitty gas or other aspects that make engines knock easier, I can see lower dynamic CR being a benefit.

So, for squishy piston use, some turbo applications, less ideal knock-resistant engines or knock prone environments, I can see larger LC having benefits for some.

Its nice to test both and see for yourself what it does though. You all know my preference now and why.

I also won't go into another pissing contest over this with you Richard, but I am sure Johannes (JPM) will happily discuss this further with you

[/edit]

In short:I liked the smaller LC with more duration better and I think with the 'assymetrical' valve timing (as I call it), I think you can regain some of the high end hp while still retaining high mid-range torque from a small LC cam. Thats what I expect the Pauter cam(s) to do.

Besides, all all N/A cams of JPM are now ground on even smaller LC's (106).

[edit]: Come to think of it, I can understand the use of larger LC's if you have a big dome on the intake side of the piston ie squishy pistons: larger LC retards the intake valve timing: later opening and later closing of the intake valve. Like you said correctly, later closing gives a lower dynamic CR (for me this usually means less max torque) while keeping duration. For me thats a huge negative, but for some who can use only shitty gas or other aspects that make engines knock easier, I can see lower dynamic CR being a benefit.

So, for squishy piston use, some turbo applications, less ideal knock-resistant engines or knock prone environments, I can see larger LC having benefits for some.

Its nice to test both and see for yourself what it does though. You all know my preference now and why.

I also won't go into another pissing contest over this with you Richard, but I am sure Johannes (JPM) will happily discuss this further with you

[/edit]

T4T: 2,4ltr Type 4 Turbo engine, 10.58 1/4 mi

www.apfelbeck.nl

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

www.apfelbeck.nl

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

-

70dragbug

- Posts: 534

- Joined: Sun Oct 27, 2002 1:01 am

Re: Camshaft grinds for turbo

Without taking sides,what I am missing in this discussion is basically valve timing vs. displacement. LC here and there is fine and it affects dynamic compression immensly,but the displacement will dictate that.Cylinder pressure is dependant on the volume of the cylinder and how much air can be compressed during the compression event.You need to calculate your cylinder pressure and the "loss" of pressure during overlap or when the intake opens at BDC.Valve lift will also play a big role in that calculation also.

-

miniman82

- Posts: 3944

- Joined: Sun Apr 27, 2008 3:36 pm

Re: Camshaft grinds for turbo

IMO it doesn't matter about displacement either. Just because you build a huge engine, does that necessarily mean it won't be used for high RPM racing? Similarly, if you build a smaller engine, does that automatically mean it gets a small cam because it's going to be driven on the street? It's about application and RPM range. Granted larger engines can generally tolerate a larger cam than a smaller one with the same goals in mind, but that doesn't dictate which cam gets picked over another.

- turbobaja

- Posts: 2826

- Joined: Fri Sep 14, 2007 4:56 pm

Re: Camshaft grinds for turbo

My cam and engine combo is on the other end of the spectrum from what most of you horsepower junkies are looking for I'm sure  . This is in my 82x90.5 all CB Performance parts engine in a very heavy baja. When I sourced most of my parts from Pat @ CB, 7 or 8 years ago, he offered me this little camshaft to meet my low-revving, high torque goals. It has no part numbers on it, but is pretty close to an Engle 100.

. This is in my 82x90.5 all CB Performance parts engine in a very heavy baja. When I sourced most of my parts from Pat @ CB, 7 or 8 years ago, he offered me this little camshaft to meet my low-revving, high torque goals. It has no part numbers on it, but is pretty close to an Engle 100.

Eagle Racing Cam on 107° lobe centers. 1.4 rockers gives me .450" valve lift and 238° dur @ .050". 24° overlap @ TDC. Pretty non-'assymetrical' valve timing.

Intake Opens 16° BTDC

Intake Closes 42° ABDC

Exhaust Opens 50° BBDC

Exhaust Closes 8° ATDC

These are the results with 7.5psi boost and a marginal tune blowing through dual Dell 40s w/MSD ignition. Cima/Mahle P/Cs, .065" deck, 42x37.5 valves, 65cc chambers ~8.1:1 static CR. Turning 31" tires through an 091 Bus box.

This was at a local hot rod engine building shop that does mostly big V8 stuff. They warned me that they usually give the lowest #s around. It's not an "internet Dyno" as they put it...not going to get a big number that I can go brag to all my internet friends with , so it should be a very realistic # and something I can use as a reference for future changes

, so it should be a very realistic # and something I can use as a reference for future changes  .

.

Eagle Racing Cam on 107° lobe centers. 1.4 rockers gives me .450" valve lift and 238° dur @ .050". 24° overlap @ TDC. Pretty non-'assymetrical' valve timing.

Intake Opens 16° BTDC

Intake Closes 42° ABDC

Exhaust Opens 50° BBDC

Exhaust Closes 8° ATDC

These are the results with 7.5psi boost and a marginal tune blowing through dual Dell 40s w/MSD ignition. Cima/Mahle P/Cs, .065" deck, 42x37.5 valves, 65cc chambers ~8.1:1 static CR. Turning 31" tires through an 091 Bus box.

This was at a local hot rod engine building shop that does mostly big V8 stuff. They warned me that they usually give the lowest #s around. It's not an "internet Dyno" as they put it...not going to get a big number that I can go brag to all my internet friends with

Karl

DON'T QUIT

DON'T QUIT

- Wally

- Posts: 4563

- Joined: Mon Oct 28, 2002 12:01 am

Re: Camshaft grinds for turbo

I couldn't agree more! Its mostly about head flow relative to the displacement. If so, then engine size is not really an item anymore.miniman82 wrote:IMO it doesn't matter about displacement either. Just because you build a huge engine, does that necessarily mean it won't be used for high RPM racing? Similarly, if you build a smaller engine, does that automatically mean it gets a small cam because it's going to be driven on the street? It's about application and RPM range. Granted larger engines can generally tolerate a larger cam than a smaller one with the same goals in mind, but that doesn't dictate which cam gets picked over another.

Like I said, its a complicated subject because so much depends on other engine/environment specifics and you not always get to hear all details when examples are thrown about.

Tbh, I thought smaller engines needed smaller cams too at first. If the head flows enough, that is not the case though I noticed, hence I agree so much with the above and why I am looking for a more duration cam for the extremely small 1200cc competition engine.