type 4 turbo 2.0L

- turbobaja

- Posts: 2826

- Joined: Fri Sep 14, 2007 4:56 pm

Re: type 4 turbo 2.0L

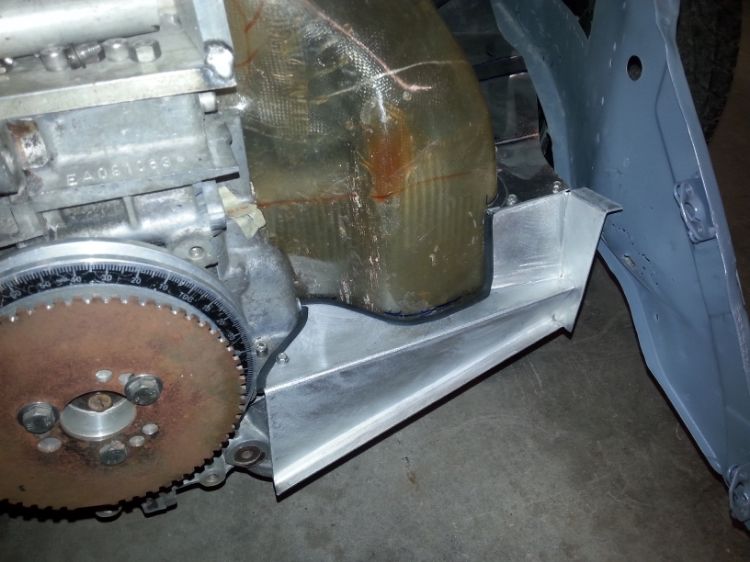

WOW! That's a tight fit in there! Looking really good though. Lots of progress, must feel good. Is there going to be a cover over that filter element? Looks like it's gonna breath in the hot air from the shroud down there, but probably won't be a big deal with E85  . Gonna be slick with the deck lid shut, what a sleeper!

. Gonna be slick with the deck lid shut, what a sleeper!

Karl

DON'T QUIT

DON'T QUIT

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

Re: type 4 turbo 2.0L

It does doesn't it

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

Re: type 4 turbo 2.0L

turbobaja wrote:WOW! That's a tight fit in there! Looking really good though. Lots of progress, must feel good. Is there going to be a cover over that filter element? Looks like it's gonna breath in the hot air from the shroud down there, but probably won't be a big deal with E85. Gonna be slick with the deck lid shut, what a sleeper!

Yes it does feel nice. I needed a brake from the body work

If I need to do a head retorquing or something of the sort all I need to do is pop off the intake, shroud, and aluminum tin and there is tons of access with no need to drop the block, exhaust, oil lines, etc

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: type 4 turbo 2.0L

interesting, i just fitted an early type beetle seal to my beetle and its bettwe then the late ones, in terms of custom use, but the foam seems better again!

Looking great!!

Looking great!!

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: type 4 turbo 2.0L

The bay bus "H" seals are a t4 swaps best friend.

They can cover a multitude of sins.

I have tried making similar with a stripe of glue down the middle of some large neoprene foam pipe insulation, sliced down each side, but it never came out quite right.

They can cover a multitude of sins.

I have tried making similar with a stripe of glue down the middle of some large neoprene foam pipe insulation, sliced down each side, but it never came out quite right.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

Re: type 4 turbo 2.0L

The foam seal allows a ton of flexibility as well as the simplicity of not needing a accommodate a channel to hold the rubber split seal. Also helps with the "factory" look I'm ultimately going for.

Close to having this half of the breast plate sealed off, have another side piece to fab and weld on and pop rivet everything together. Sheet metal screws are temp . Only cold air allowed

. Only cold air allowed

Close to having this half of the breast plate sealed off, have another side piece to fab and weld on and pop rivet everything together. Sheet metal screws are temp

You do not have the required permissions to view the files attached to this post.

Last edited by sweetlokin66 on Fri Jan 10, 2020 8:08 pm, edited 1 time in total.

- turbobaja

- Posts: 2826

- Joined: Fri Sep 14, 2007 4:56 pm

Re: type 4 turbo 2.0L

Oh, sweet! That makes way more sense. My eyes were playing tricks on me  . Neat how your shroud covers the cylinders and all in one smooth piece rather than the multi-piece skirts of a T-1 shroud...no pesky exhaust pipes in the way...cheater

. Neat how your shroud covers the cylinders and all in one smooth piece rather than the multi-piece skirts of a T-1 shroud...no pesky exhaust pipes in the way...cheater

Karl

DON'T QUIT

DON'T QUIT

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

Re: type 4 turbo 2.0L

McMaster has been my best friend. They have a ton of rubber sealing options available. I may have even found a bulb seal that may work out for the doors. Gunna buy a test piece and see if it works. I'm just trying to wrap up this engine tin ATM.Piledriver wrote:The bay bus "H" seals are a t4 swaps best friend.

They can cover a multitude of sins.

I have tried making similar with a stripe of glue down the middle of some large neoprene foam pipe insulation, sliced down each side, but it never came out quite right.

- ToRy 70

- Posts: 1338

- Joined: Tue Jun 08, 2004 1:00 pm

Re: type 4 turbo 2.0L

Is that the airbox on your apron? Looks great!

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

Re: type 4 turbo 2.0L

Yeah  The only way to fit the size filter I needed and be able to keep it on the clean air side was to run this kind of a setup. Worked out really well. Super easy to take the apron and filter on and off in one sweep.

The only way to fit the size filter I needed and be able to keep it on the clean air side was to run this kind of a setup. Worked out really well. Super easy to take the apron and filter on and off in one sweep.

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

- sweetlokin66

- Posts: 280

- Joined: Thu Jun 05, 2008 10:02 pm

-

GARRICK.CLARK

- Posts: 620

- Joined: Fri Aug 26, 2011 10:01 am

Re: type 4 turbo 2.0L

Looking good.

Just something to watch for, On my type 4 turbo (blow through) I had a large intercooler like yours. What I experienced was that the boost/air speed would drop off as it entered the big volume cooler, The turbo had to work harder to put the PSI into the heads. Removed the cooler and the lag was considerably reduced.

Good luck.

Just something to watch for, On my type 4 turbo (blow through) I had a large intercooler like yours. What I experienced was that the boost/air speed would drop off as it entered the big volume cooler, The turbo had to work harder to put the PSI into the heads. Removed the cooler and the lag was considerably reduced.

Good luck.