Spot welder

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Spot welder

Does anyone know of a url for how to spot weld; e.g., how long to hold it based on material size?

Lee

Lee

-

5.0 Chero

- Posts: 74

- Joined: Sat Jun 20, 2015 7:47 am

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

Thank you sir. I will certainly look at them. My tablet won't let me open it but it will get opened and looked at. I had found another one but the sound was so scratchy that the important things were not understandable.

Thanks again, they well be looked at. I have plans that may or maynot work.

Lee

Thanks again, they well be looked at. I have plans that may or maynot work.

Lee

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

I have looked at both of them and they are what I needed. Thank you very much! Still need to learn a lot

Lee

- SCOTTRODS

- Posts: 626

- Joined: Sun Nov 07, 2010 7:15 am

Re: Spot welder

Hold it til it Splatters, Lee... LOL

It actually works on non-critical items in most cases. especially thinner metals. When the electrodes Connect, it doesn't do much until the Substrate gets hot enough to splatter. I spot welded for about 7 years with no formal training... Mostly on 16 and 18 gauge Galvanized. ON occasion we had some stubborn material we had to do more time on. That was usually on VERY thick stuff. Generally speaking, the metal will go red hot for more than a second, and with pressure on the "spot" it fuses together. I know you've welded, so use your welding knowledge to know when it fuses too.

You buy a Spot welder?

It actually works on non-critical items in most cases. especially thinner metals. When the electrodes Connect, it doesn't do much until the Substrate gets hot enough to splatter. I spot welded for about 7 years with no formal training... Mostly on 16 and 18 gauge Galvanized. ON occasion we had some stubborn material we had to do more time on. That was usually on VERY thick stuff. Generally speaking, the metal will go red hot for more than a second, and with pressure on the "spot" it fuses together. I know you've welded, so use your welding knowledge to know when it fuses too.

You buy a Spot welder?

I have found them completely missing more than once. - PILEDRIVER

Some pics of My Powder Coating work

http://s244.photobucket.com/albums/gg6/terrellster/

My Facebook Page for Powder Coating

http://www.facebook.com/profile.php?id=100001788886297

Some pics of My Powder Coating work

http://s244.photobucket.com/albums/gg6/terrellster/

My Facebook Page for Powder Coating

http://www.facebook.com/profile.php?id=100001788886297

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

I've welded before.... Pshaw... I weld so infrequent that it is like starting over everytime.SCOTTRODS wrote:Hold it til it Splatters, Lee... LOL

I know you've welded, so use your welding knowledge to know when it fuses too.

You buy a Spot welder?

Actually, I bought a 120v unit. I have made things that I didn't have enough hands, arms, legs, clamps and whatever to hold pieces in place much tack it... so... why not try to spot weld then do the finish welding. The 120v units (besides being on sale) are supposedly good for up to 1/8" combined stock so... what the hey.

I remember seeing someone spot weld on the very edge of the material to be joined, kind of like a tack weld but (maybe) easier to accomplish. I figured it was worth it to me to try it.

I am thinking about making a cover on my blue buggy to cover the shift rod on top of the tunnel (091 and above tunner conversion) making it less prone to be pressed on when climbing out of the buggy. It might even come in handy on the black buggy.

Lee

-

5.0 Chero

- Posts: 74

- Joined: Sat Jun 20, 2015 7:47 am

Re: Spot welder

Glad to be of some help I do fake spot welding with both a MIG and TIG welder and a drillOl'fogasaurus wrote:I have looked at both of them and they are what I needed. Thank you very much! Still need to learn a lot

Lee

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

Yeah. I have done that myself with mixed results... which is part of the reason for getting the spot welder. I was loaned a spot welder many years ago but I couldn't get it to work right (I'm sure it was something I was doing wrong) so I gave it up. I had even gone so far as to make up a long 220/240 extension cord with a 20 amp end on it. It was a very nice unit and even was mounted on a stand. Both he and my middle stepson have since passed away so I don't have access to it now. I am still debating if I should have gone for the 240 unit or not (same price).

Lee

Lee

-

5.0 Chero

- Posts: 74

- Joined: Sat Jun 20, 2015 7:47 am

Re: Spot welder

generally speaking higher input voltage on the welder means longer duty cycle and better welds

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

Thanks, it goes back today for a swap!

Lee

I think I am going to hold off taking it back for now. It's use is not intended for major work but light duty work. Also, the 120v allows me to be able to use it in more locations. I do have the cord I built for the 240v which I could change ends on... assuming it takes more than a 20 amp connector. The 120c unit only draws 13.5 amps which, for the size stock I will be using, is probably going to be enough. Time will tell!

Lee

Lee

I think I am going to hold off taking it back for now. It's use is not intended for major work but light duty work. Also, the 120v allows me to be able to use it in more locations. I do have the cord I built for the 240v which I could change ends on... assuming it takes more than a 20 amp connector. The 120c unit only draws 13.5 amps which, for the size stock I will be using, is probably going to be enough. Time will tell!

Lee

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

Just got off the phone with an old friend who works at a business that sells spot welders (he used to work in a welding shop and repaired welders while there). He thinks that I made the right choice for the 120v unit (even where I got it) and to keep it. He said that most welding shops don't carry spot welders and call their business when one is needed (use specific usually). I think he said that the welding shops kind of look down at spot welders probably because they work with thin sheet metal.

I told him what my plan of use was and he agreed with me (he doesn't always and is quick to give reasons why).

Anyway, for what it is worth.

Lee

I told him what my plan of use was and he agreed with me (he doesn't always and is quick to give reasons why).

Anyway, for what it is worth.

Lee

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

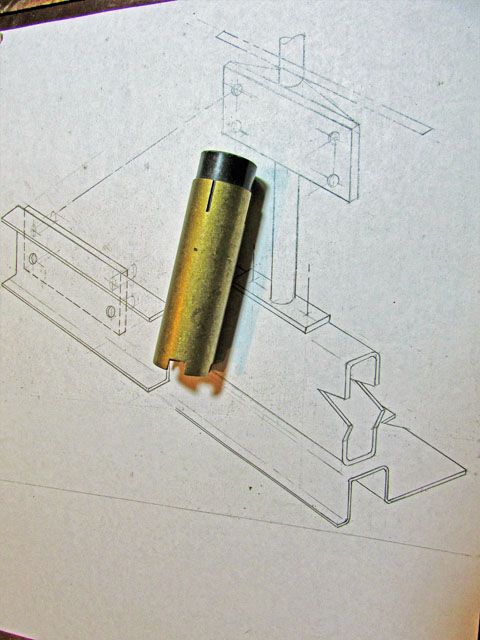

I got the arms aligned and everything adjusted. The arms are only 6" long; I asked my friend if the arms were standard and interchangeable and the answer is no! I did find out that the max length of the arms is ~18" and after that there is a big drop in working ability. Most of the stuff I want to do is going to be short/compact so not to worry so if you think you are going to need the longer reach find a maker that carries the longer arms you think you would need.

My first (and only) try. The dimple in the middle means that I held the switch on too long but I am sure that will take time to learn just how long. The 2 pieces of material ended up being close to 1/8th inch (visual measurement). Once the red started it spread quicker than I anticipated. So kool!

Lee

- raygreenwood

- Posts: 11895

- Joined: Wed Jan 22, 2003 12:01 am

Re: Spot welder

You can also get a spot weld kit for a mig welder from Eastwood. It has a pair of forked vise grips to clamp the parts and allow welding between the forks. It has a special nozzle with a leg on each side to gjve an exact standoff distance. The nozzle fits on the pliers whicj holds it still and at the exact distance. After you set voltage abd wire feed....its pretty simple and works well. I have used one I borrowed with my mig welder. Its about $75 for the whole kit. Ray

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Spot welder

Common feature in larger TIG units as well.

My Synchro 250 has a knockout/label for a spot weld timer.

I have done it just lighting up an arc until it sticks...

But I imagine it would work better with the proper gear.

Olde school welders were named//rated current at 100% duty cycle.

I don't think the marketing numbers mean much with newer units.

...More like "current output if it takes a direct lightning strike while welding"

Here's a slick little TIG spot weld setup from Eastwood, although you could do same just as easily with std tooling:

https://www.youtube.com/watch?v=3-LSuFsqoWc

My Synchro 250 has a knockout/label for a spot weld timer.

I have done it just lighting up an arc until it sticks...

But I imagine it would work better with the proper gear.

Olde school welders were named//rated current at 100% duty cycle.

I don't think the marketing numbers mean much with newer units.

...More like "current output if it takes a direct lightning strike while welding"

Here's a slick little TIG spot weld setup from Eastwood, although you could do same just as easily with std tooling:

https://www.youtube.com/watch?v=3-LSuFsqoWc

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Spot welder

I looked at that video before I went out and bought what I now have. For what I think I want to do with the spot welder, I don't think the MIG will do what I want as well plus I think I would need more hands and feet to do it. I am jealous of the pilers though; gimmie, gimmie, gimmie!raygreenwood wrote:You can also get a spot weld kit for a mig welder from Eastwood. It has a pair of forked vise grips to clamp the parts and allow welding between the forks. It has a special nozzle with a leg on each side to gjve an exact standoff distance. The nozzle fits on the pliers whicj holds it still and at the exact distance. After you set voltage abd wire feed....its pretty simple and works well. I have used one I borrowed with my mig welder. Its about $75 for the whole kit. Ray

I do have a special nozzle somewhere for doing the spot/plug/rosette welding but it is too large of diameter for my Hobart 120. I have also thought of buying another back up nozzle and modifying it like is shown in the video.

When doing my pans I tried to do the plug/rosette welds like that but because I had too small of holes and the problems of the pollution of the steel, the lack of room for the nozzle against the tunnel and the warped tunnel flange I had it was a bust.

I also looked at another video of a guy making a string of the nicest tack welds I have ever seen... I wish that I could do that. I took extreme notice on how he did it but there are times where using the method he did there isn't room to do it. Pretty though; Hmmm!

As I told someone (it may have been here long day]) the longes tongs are 18", after that there is a big drop in working ability. The diameter of the tongs is not a standard so if you want to get something with the ability to have several different lengths of tongs then you have to consider that when purchasing your spot welder.

On one of the "how to do it" car shows today they showed putting a new top on a car (first Gen Bronco). Instead of using rosette/plug welds they used an overhead drop down spot welder with flat tongs. No room in the drip rail for a rosette weld (MIG of TIG) to be done plus the drip rail would not be flat so the water would collect not flow.

My guy I talked to locally works for a company that caters to selling tools to sheet metal workers. He said that many, if not all, of the welding shops don't normally stock spot welders as they deal with working with thin stock not honking thick chunks of metal. When the need comes up they come to them for what ever they need.