Hand Packed bearings and slick shift

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Hand Packed bearings and slick shift

Thanks for the clarification, Henry. Wheel hop on the track with sticky tires will usually damage trans internals .. and serious off-road jumps are without a doubt far worse. We used to see the Gem 8620 synchro teeth strip, as well as VW 113, which typically had only 9 drive teeth.

But .. I'm hoping fastback's trans will get 100 passes before requiring inspection/rebuild.

But .. I'm hoping fastback's trans will get 100 passes before requiring inspection/rebuild.

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Hand Packed bearings and slick shift

Have you seen the 113 gears that used 2 sets of 5 teeth? Most have 3 sets of 3 that only get used but some had 2 sets of 5. I have "knocked off" the 3 sets of 3 and that leaves 3 sets of 7 I think? But I have never tried knocking off the 2 sets of 5.. have you?

VW really did some strange things and a couple stand out that I have never really understood.

One is why did they use straight or square teeth on the inside of their sliders and have the synchro cone teeth wedged or tapered..why not taper/wedge both? ( I know they did change them in later years). It is strange to me that it even works, but it does/did. Also, on their 1st/2nd sliders, why are the engagement teeth recessed back into the slider? Shouldn't they be even with the slider? I mean the dog teeth on the cones are barely long enough anyway. Sometimes I wonder what their engineers were thinking, lol.

VW really did some strange things and a couple stand out that I have never really understood.

One is why did they use straight or square teeth on the inside of their sliders and have the synchro cone teeth wedged or tapered..why not taper/wedge both? ( I know they did change them in later years). It is strange to me that it even works, but it does/did. Also, on their 1st/2nd sliders, why are the engagement teeth recessed back into the slider? Shouldn't they be even with the slider? I mean the dog teeth on the cones are barely long enough anyway. Sometimes I wonder what their engineers were thinking, lol.

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Hand Packed bearings and slick shift

Oh yes .. I've seen some head-scratching changes over the years. If you go back and look at the split-case transaxle synchro tooth geometry, you'll find some synchro cones in which groups of teeth contact on drive, but not on coast. But, all in all, the VW engineers were ahead of their Porsche counterparts in the area of synchro tooth geometry, synchros, and associated parts.

I do believe in deepening the engagement whenever possible (and of course the corresponding mods to the shift detent positions).

.. and out of the cobwebs comes one more mod fastback must perform. This concerns the 1st/2nd shift rail, as the convoluted shifting mechanism in the Type II nosecone was never meant to be speed-shifted. A "pathway" sloping back toward neutral detent groove should be ground starting at the 2nd gear detent groove, which assures that this shift rail ends up in neutral when speed-shifting from 2nd to 3rd. Otherwise, the shifter will (at some time or another .. Murphy's law says your most important race) end up stuck in neutral position, while the trans remains in 2nd gear.

I do believe in deepening the engagement whenever possible (and of course the corresponding mods to the shift detent positions).

.. and out of the cobwebs comes one more mod fastback must perform. This concerns the 1st/2nd shift rail, as the convoluted shifting mechanism in the Type II nosecone was never meant to be speed-shifted. A "pathway" sloping back toward neutral detent groove should be ground starting at the 2nd gear detent groove, which assures that this shift rail ends up in neutral when speed-shifting from 2nd to 3rd. Otherwise, the shifter will (at some time or another .. Murphy's law says your most important race) end up stuck in neutral position, while the trans remains in 2nd gear.

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: Hand Packed bearings and slick shift

oops i did not read this last post.

now the tranny is almost finished.

do you mean a deeper groove for the rails in neutral or a sort of grove between the detents in tha rails?

pictures tell more than thousand words. especially for us foreigners

good tip which i can do next time i open the box,(could e in a short time )

)

now the tranny is almost finished.

do you mean a deeper groove for the rails in neutral or a sort of grove between the detents in tha rails?

pictures tell more than thousand words. especially for us foreigners

good tip which i can do next time i open the box,(could e in a short time

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: Hand Packed bearings and slick shift

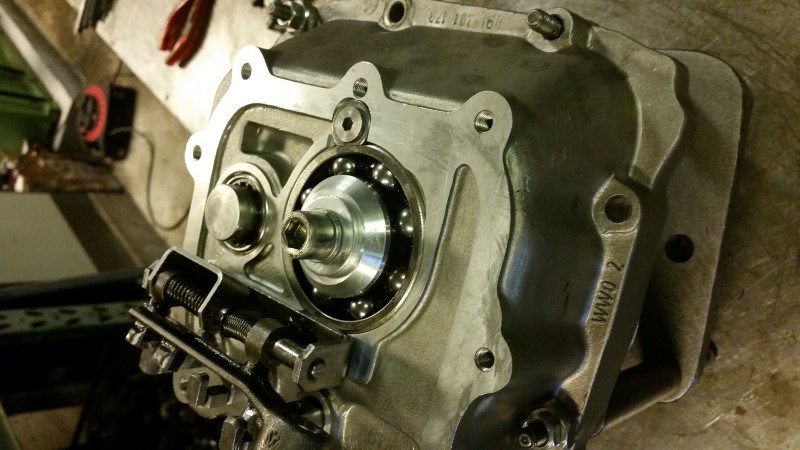

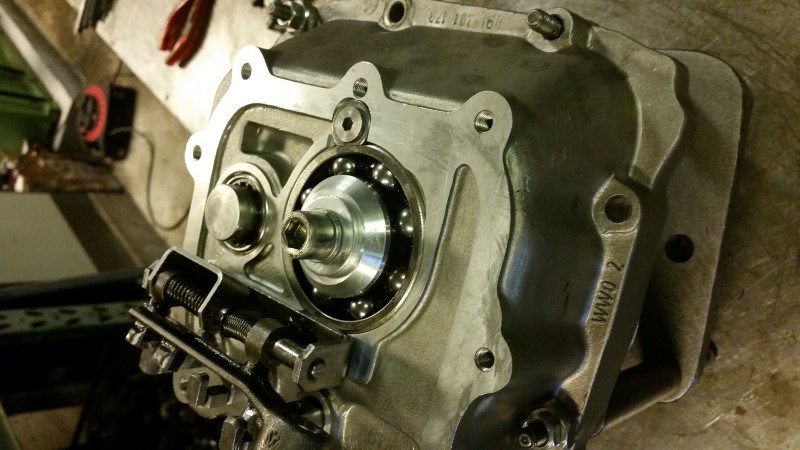

the weddele hub has to be returned for a new better one.

so i found another late hub and got the 3/4 gear play within "spec" but still on the high side.

as i will race the weekend 16/17 aug.

playing with the gear calc i made a last minute change to get a lower ratio

i had a very good 5,43 R/P so i take a chance on this

teoretically ,i will hit very close to max power/rev limit on 4.th at 1/4 based on earlier top speed passes.

made a alu "washer" for the bolt that holds the mainshaft in the bearing

some grinding needed inside the nosecone to accpet the bolt that sticks out

adjusted the forks in the jig

also checked the "r" numbers (50)from the ring gear and was within 2/100.

so tomorrow the ring gear goes on the ZF and the tranny is ready to go into the car after i set backlash

~0.12 for a dragrace ok??

so i found another late hub and got the 3/4 gear play within "spec" but still on the high side.

as i will race the weekend 16/17 aug.

playing with the gear calc i made a last minute change to get a lower ratio

i had a very good 5,43 R/P so i take a chance on this

teoretically ,i will hit very close to max power/rev limit on 4.th at 1/4 based on earlier top speed passes.

made a alu "washer" for the bolt that holds the mainshaft in the bearing

some grinding needed inside the nosecone to accpet the bolt that sticks out

adjusted the forks in the jig

also checked the "r" numbers (50)from the ring gear and was within 2/100.

so tomorrow the ring gear goes on the ZF and the tranny is ready to go into the car after i set backlash

~0.12 for a dragrace ok??

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: Hand Packed bearings and slick shift

a note to the strenght discussion here , looking into parts in the drive train there is several parts that look very fragile that keeps up with the torque/inertia of the engine

the small splines on the input shaft and the small diameter that has

and looking at a clutch disc , the puny small "sheet metal " that connects the outer part to the center part

the hold up pretty good.

so compare this to the engagement teeth on the gears , 15 teeht should hold up good.??

the small splines on the input shaft and the small diameter that has

and looking at a clutch disc , the puny small "sheet metal " that connects the outer part to the center part

the hold up pretty good.

so compare this to the engagement teeth on the gears , 15 teeht should hold up good.??

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: Hand Packed bearings and slick shift

also looked at the weddle hub and gears compared to stock

my supplier says the weddle hub is compatible with both stock and (of course) weddle gears

but the weddle gears has the axial thrust going to the outer diameter on the hub

when stock vw has it in the center

would'nt it make more stress om the hub having the thrust "out there" making it more voulnarable to flexing??

my supplier says the weddle hub is compatible with both stock and (of course) weddle gears

but the weddle gears has the axial thrust going to the outer diameter on the hub

when stock vw has it in the center

would'nt it make more stress om the hub having the thrust "out there" making it more voulnarable to flexing??

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Hand Packed bearings and slick shift

I would not think there should be near enough thrust against the hub to flex it. Maybe I am wrong but I think it would surely gall the gear and/or hub before it even got close to enough pressure to flex/ bend it. Also, since Weddle uses chromoly, it should be stronger as well.

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Hand Packed bearings and slick shift

Also, you will break 1st and 2nd gear before the input splines strip....as for the clutch discs, breakage is somewhat rare unless it was a spring type.

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Hand Packed bearings and slick shift

Hopefully Pablo has a pic of this, but he is correct, bus boxes do not speed shift well.There used to be an intermediate housing that one buy that converted it to a type one shift configuration.fastback wrote:oops i did not read this last post.

now the tranny is almost finished.

do you mean a deeper groove for the rails in neutral or a sort of grove between the detents in tha rails?

pictures tell more than thousand words. especially for us foreigners

good tip which i can do next time i open the box,(could e in a short time)

-

Bruce2

- Posts: 7087

- Joined: Sat Oct 13, 2001 1:01 am

Re: Hand Packed bearings and slick shift

The ZF will not survive. In the first few passes you will blow up the tiny spider gears. The only help I can think of is to add more discs so the discs take more of the load than the spiders.fastback wrote: the ring gear goes on the ZF and the

Also, you should drill big holes in the side of the housing to let oil in.

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Hand Packed bearings and slick shift

So which will break first? Just ribbing you fastback! Will it be 1st gear ? ZF? Ring and pinion? Lol.

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: Hand Packed bearings and slick shift

well something may/will break! sooner or later

i hear some are negative to this ZF but i only have good experience with it.

the spiders are small yes , but they rest in a housing that seem to be very good quality steel

which maybe adds up for the spiders beiing smaller??

i'd rather use the ZF than a china super diff.

the 094 4 spider diff , i belive is not that strong either

i have run a 094 ZF in my bus for 6 years now , had more discs in it and drilled holes

my intensions with the extra discs was to get more lockup

this is in a 2380LBS bus + driver , with semislicks running turbo engines up to 571 whp .dragrace and circletrack. even had puny "wheels up" with it

i have broken 2 axles on dragrace and one CV joint on in circltrack on those 6 years.

but no clutch sidestep and dragslicks though..

now i have bought a set of Hoosiers DOT drag radials, so grip will be better.

i took the ZF apart yesterday and internals look ok. minor wear.

but the other ZF i have which goes into this tranny is a stock setup.

i can do the oil mod to this also, but i do not have more discs to tighten it up

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: Hand Packed bearings and slick shift

some stock hubs and gears have galling on them yes.Henryhoehandle wrote:I would not think there should be near enough thrust against the hub to flex it. Maybe I am wrong but I think it would surely gall the gear and/or hub before it even got close to enough pressure to flex/ bend it. Also, since Weddle uses chromoly, it should be stronger as well.

most likely to oil starvation?

there must be a cignificant force to the hub's since the stock ones break , even with the thrust is in the center on the stock hubs.

then adding axial forces to the "weaker" part of the hub may look like adding more stress to that area.??

but as you state a better steel quality maybe does the trick.

and hopefully weddle know what they're doing

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: Hand Packed bearings and slick shift

yes i have Berg bus 600 converison in my squarback,fastback wrote:Henryhoehandle wrote:Hopefully Pablo has a pic of this, but he is correct, bus boxes do not speed shift well.There used to be an intermediate housing that one buy that converted it to a type one shift configuration.fastback wrote:oops i did not read this last post.

now the tranny is almost finished.

do you mean a deeper groove for the rails in neutral or a sort of grove between the detents in tha rails?

pictures tell more than thousand words. especially for us foreigners

good tip which i can do next time i open the box,(could e in a short time)

but its a 002 5 rib case with shorte gears

Land products had this type 1 shifter conversion available for the 091 some time ago

much better shifting on this one than a stock 002/091 style .

but i will not convert to that style , due to much work with gear mechanism in this car

only small mod i have done is to try smooth out the edges on the rails/shift mechanism and added a steel ball for the hockey stick

i'm not trying to make the best 091 ever