Thanks again, as always, Paul.

Nobody ever did a 915 build here, and when you started your detailed answering, I just ran with it.

Figured it's good to have this all here for posterity..

A lot of time my words aren't exactly thought through before I post, though..

Funny,

Spent an evening digging for that bushing,

And it's amazing how many sources there are for Porsche parts and info.

You can even go to the Manufacturer's website and download the parts catalog!

Coming from VW world, especially doing a type 3, I just automatically assume everything is NLA!

Found the bushing at the Sierra Madre Collection - a place with a VERY expensive-sounding name.

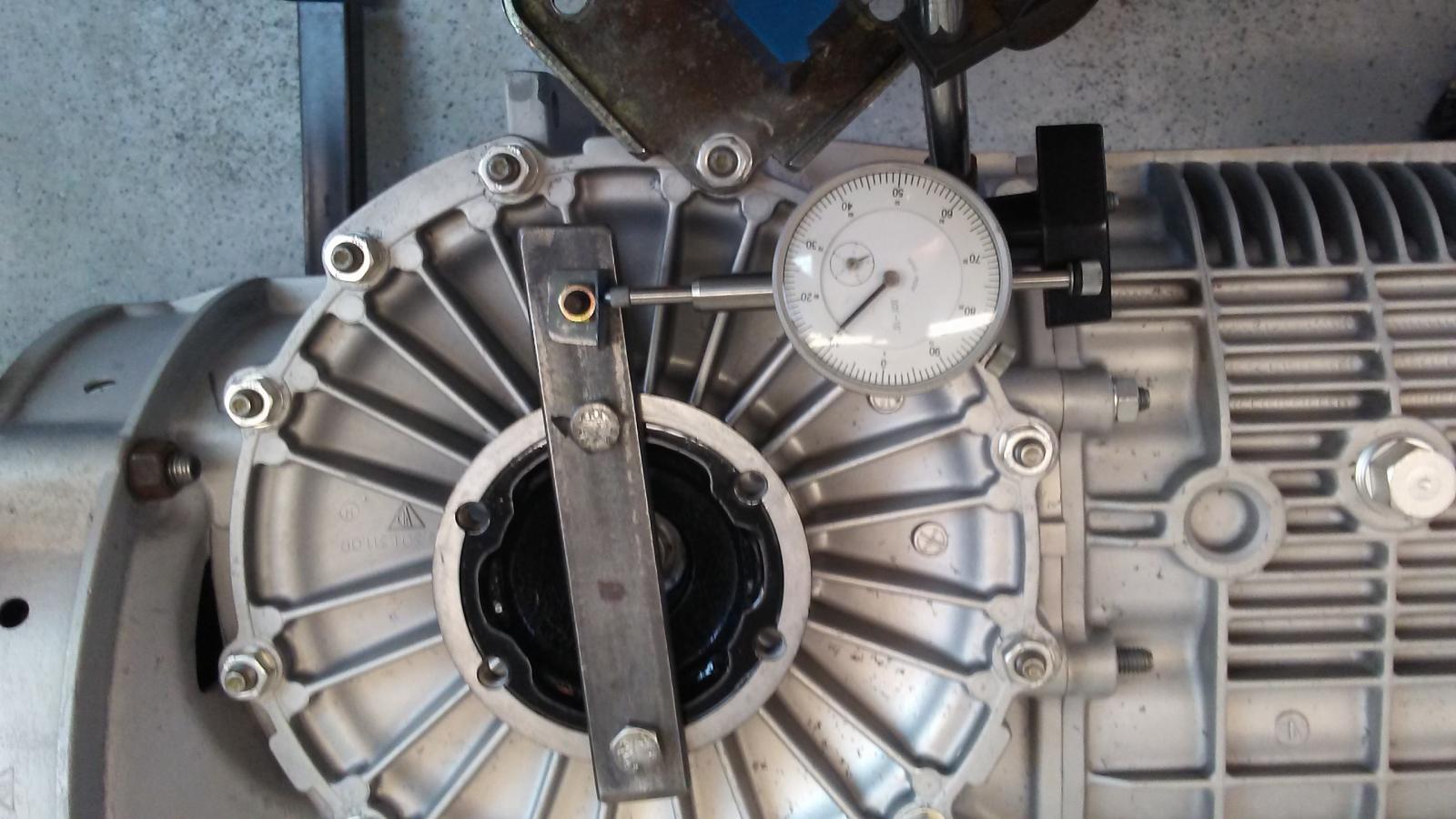

Double-checked my distance from center, where the R&P backlash gets measured;

76.5mm, or 3.0118" inches.

Got some SKF diff bearings on the way from Pelican, along with a gallon of Swepco 201 and some throwout shaft bushings.

But,

Having reservations about installing them diff bearings.

I'm kinda skeered, TBPO.

They already feel plenty tight from all of my years' experience doing other things like this.

Here's a diatribe/tangent that will be long and nonsensical, but I'll put it up here anyways:

A few years' experience as a machinist haunts me in another way;

The theory of 'work hardening' a.k.a. breaking in.

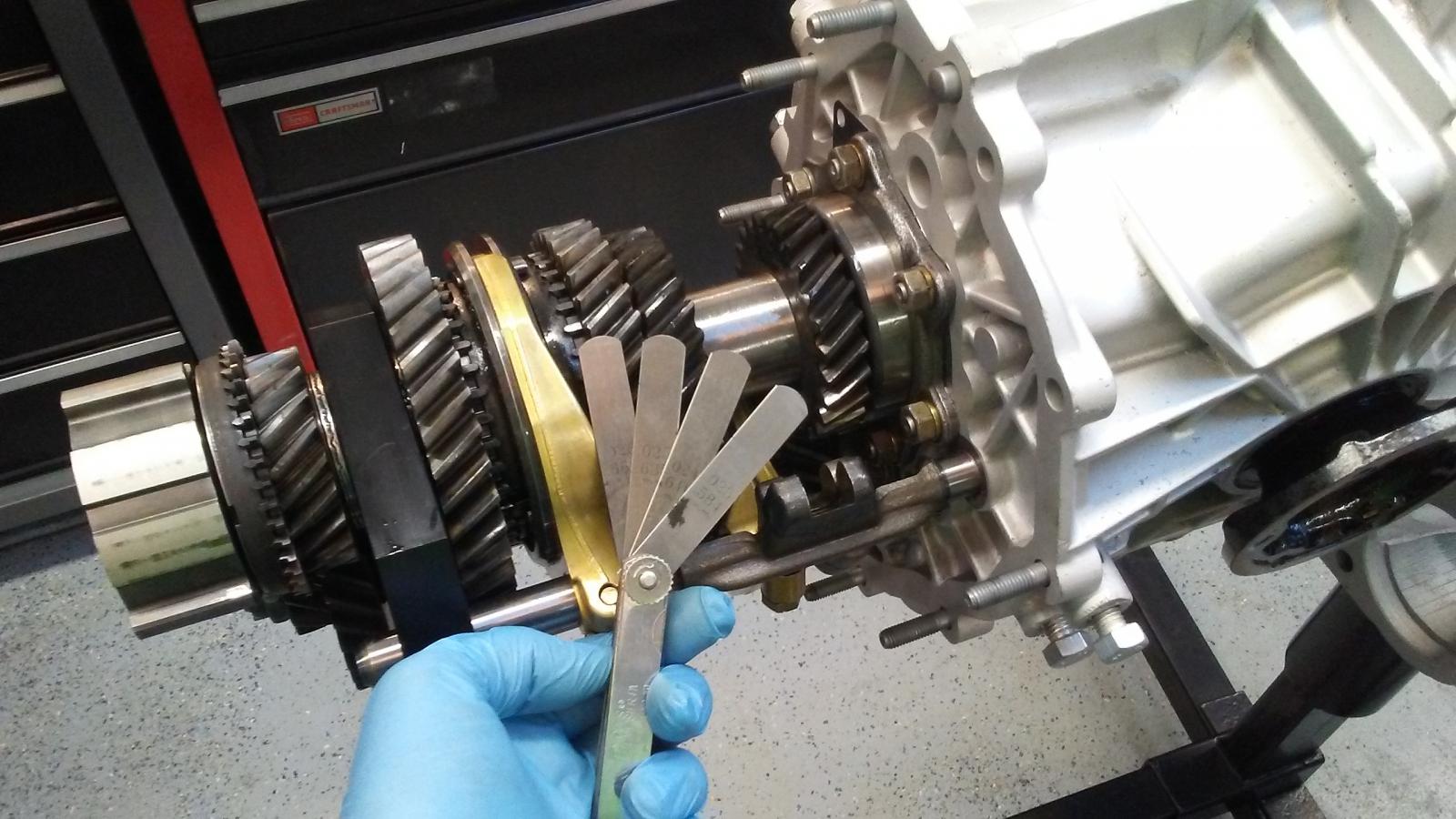

Those diff bearings get 'pounded in', 'bedded in', through use.

I see the rollers getting made smaller and harder, and the races made thinner.

The wear parts of the bearing get compacted, they don't wear away.

Pressure is at work on them, not abrasion.

They might have less pre-load on them now,

But they are worn in perfectly to each other, and shaped in exactly the correct way to work in harmony.

They are hard in exactly the right spots where they are subject to the most pressure during use.

They are likely to last a good while longer, as long as everything goes back together with no changes.

Any changes in geometry here, or dirt intrusion, obviously will cause rapid wear,

But,

If it all gets cleaned and goes exactly back together..?

I'm really skeptical of what I might accomplish by installing new diff bearings and tightening the preload.

Some things like this I did in the past didn't end so well in the long run.

Pre-load will just open up as new parts wear in.

Changing the backlash might make the R&P 'sing' on the highway.

Because the rest of the parts of this trans were in pretty good shape,

I'm ready to believe the story about low mileage and the dentist.

I know for sure the 'fire' part of the story is true.

Paid a guy ($1000(!)

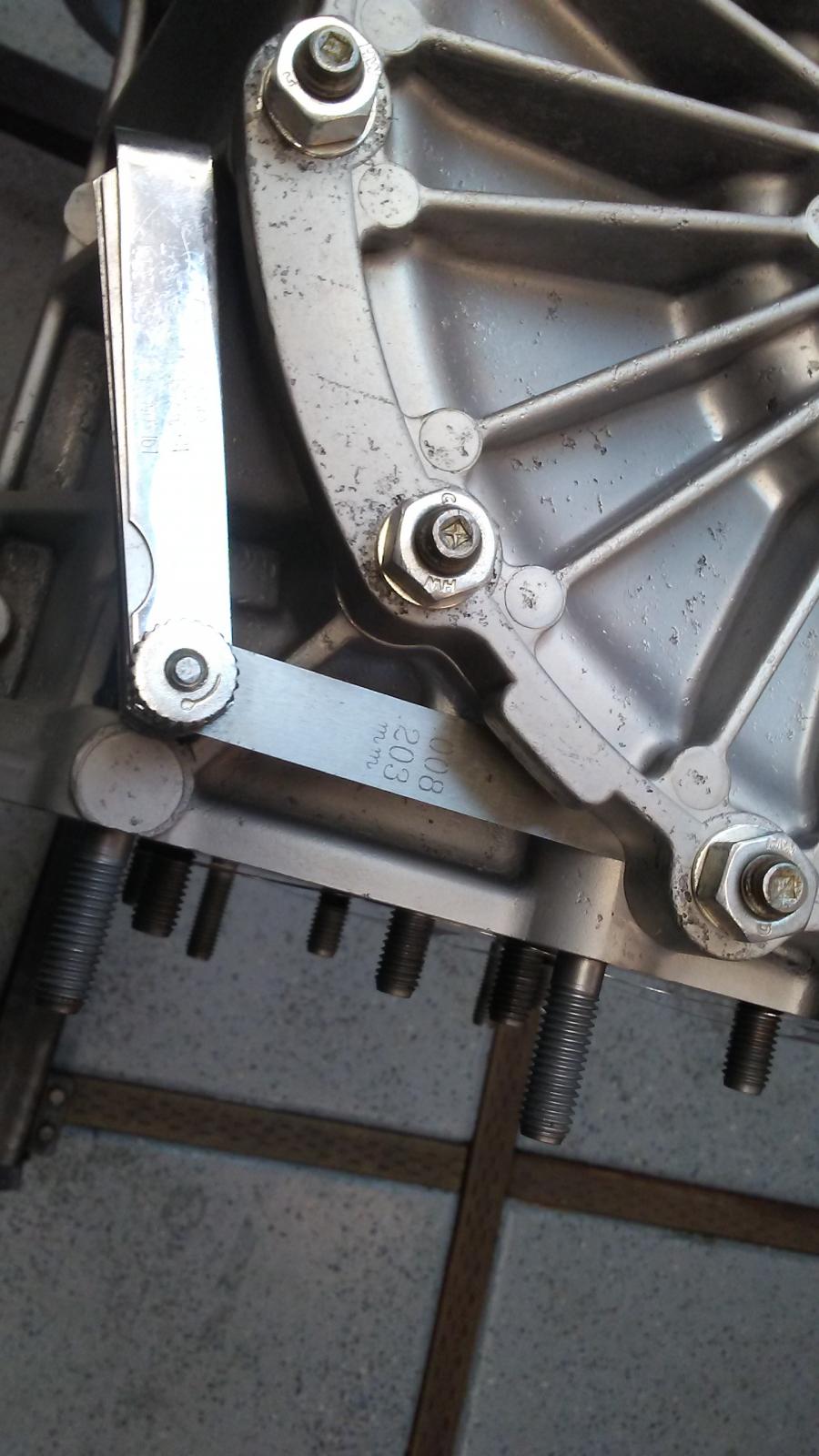

) to go in there and look at everything (and mangle my shim),

And he said it all looked like a low-mileage box that was never opened

(for whatever that is worth).

One of my main goals was to know what was going on in there, and to de-mystify these internals;

To check things out, and see with my own eyes what was in there.

Should there be any issues with this trans, I'm all set to go back in there and continue along.

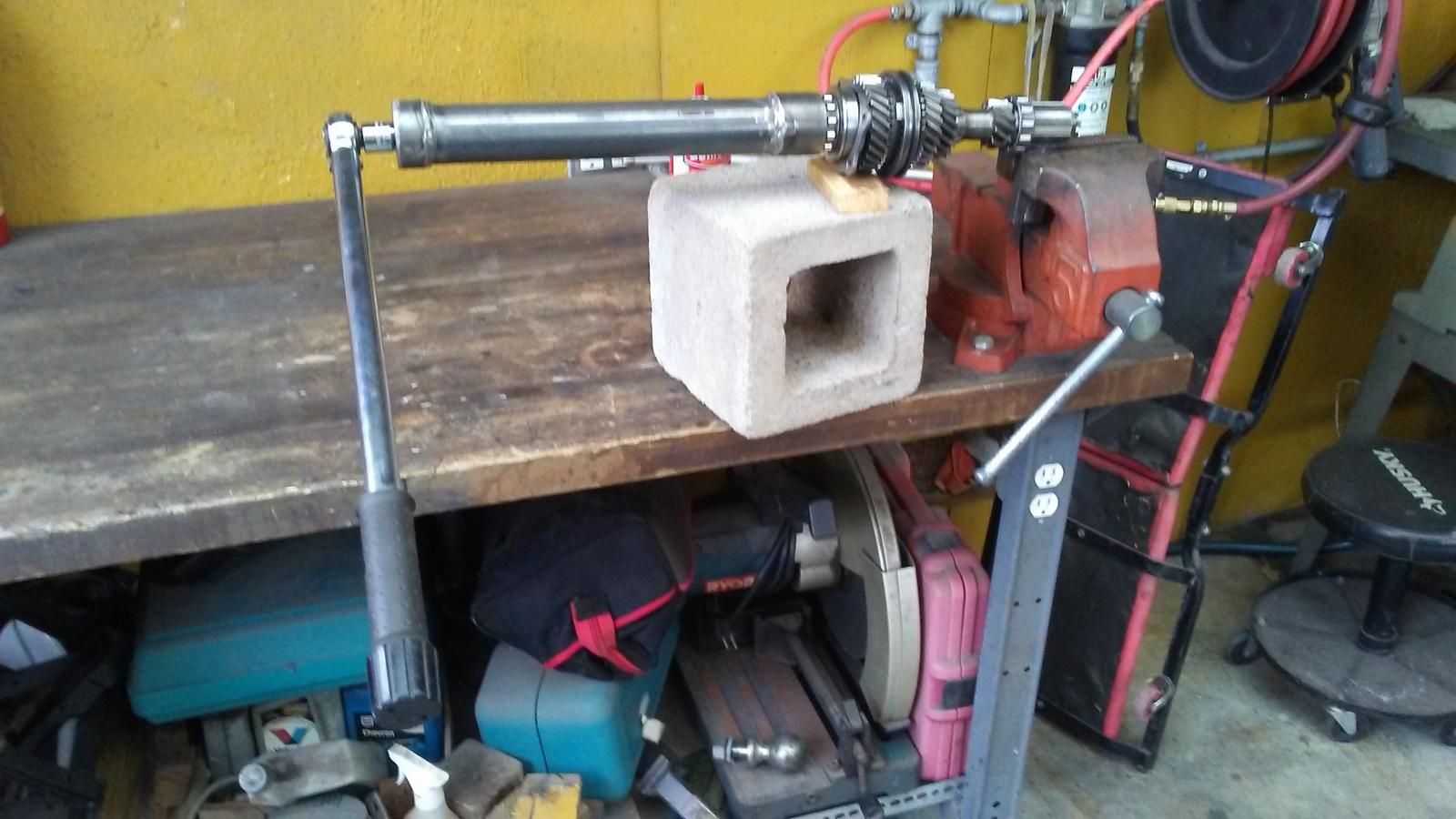

The tools are all made up and most everything to build these is right here.

If there is any balky shifting, or the trans sings, or..? We're all set to dig right back in.

Things like case blasting and fastener plating and throwout bushings won't need to ever be done again.

I'll be able to save up for a nice dial inch-pound wrench and a complete set of bearings, and a billet bearing retainer and billet side cover..

(OK, maybe I'm lying about the side cover

).

It would, however, be great timing, if you were setting up diff pre-load anyways, to get a billet side cover, right?

This car is going to be driven occasionally, on the street, by an old man.

It will go to shows, and cars n' coffee, maybe to work on Friday.

The motor is a feeble pushrod 4-banger.

It's not some 3.2 Carrera being driven daily.

This car has an experimental/home-made shift linkage that I don't even know will work.

I'm not shop or professional mechanic with a reputation to maintain.

A come-back just means more fun!

Especially now that everything is clean, and I'm all tooled up..

I have the next week off for the holidays, which is rare.

The stuff is all sitting here ready to go..

So,

I'm Pussing Out, and throwing it back together.

The new diff bearings will be sitting here on the shelf with my new trans tools.

I know I might regret it later,

But there are just WAY too many other fish to fry with this car right now...

Thanks for listening,

Send me a bill.