Catastrophic Failures

-

nshaddox

- Posts: 38

- Joined: Tue Jul 21, 2009 9:03 am

Catastrophic Failures

This forum is pretty quiet, but is also a fantastic resource. Proposing a thread to document some catastrophic failures I have/others have seen tearing down trans cores so that we can discuss what might have happened and learn from other people's screw ups.

Just tore down an oddball core with 63 only bus RGBs on a dual side cover IRS box. one of the stub axles had some chipping on the teeth, I suspect because someone installed bearing spacers incorrectly. When I pulled the differential, a bunch of bits of synchro ring were in the center section. mainshaft bearing behind the nose cone had no evidence of having a retainer to keep the balls in place. 3rd gear synchro somehow managed to completely escape from captivity between its synchro cone and the 3-4 hub, albeit in several chunks. mainshaft was junk (2nd gear w/chipped teeth), 3rd and 4th were junk (bummer since they were still bus gear ratios), 1st and 2nd idlers actually seem ok, along with R&P although I want to check runout on the pinion shaft to confirm. So the question is, what happened first? Clearly there was some odd ball stuff going on from the mis-match of parts, but was failure due to mainshaft bearing letting loose, or something else? I'm thinking mainshaft bearing allowed mainshaft to have more shock loading, especially in 3rd, which probably caused some stress risers to start cracking right at the cutouts on the 3rd synchro cone, which eventually was able to get hammered out as it broke into bite sized chunks and got hammered through the gap. Any guesses as to how long that took to happen? Other thoughts?

Only other catastrophic failures I've seen are pretty normal IMO. swing axle side gears that tear at the weld from excess load/oil starvation, fulcrum/axle spade end wear, differential wear. Brass 1-2 shift forks that are broken because they were just under designed. Corroded cases. early 1st gear with thin synchro hub thats been mushroomed over from overloading and worn/broken synchros.

Anyone else seen anything weird? I want to learn more.

Just tore down an oddball core with 63 only bus RGBs on a dual side cover IRS box. one of the stub axles had some chipping on the teeth, I suspect because someone installed bearing spacers incorrectly. When I pulled the differential, a bunch of bits of synchro ring were in the center section. mainshaft bearing behind the nose cone had no evidence of having a retainer to keep the balls in place. 3rd gear synchro somehow managed to completely escape from captivity between its synchro cone and the 3-4 hub, albeit in several chunks. mainshaft was junk (2nd gear w/chipped teeth), 3rd and 4th were junk (bummer since they were still bus gear ratios), 1st and 2nd idlers actually seem ok, along with R&P although I want to check runout on the pinion shaft to confirm. So the question is, what happened first? Clearly there was some odd ball stuff going on from the mis-match of parts, but was failure due to mainshaft bearing letting loose, or something else? I'm thinking mainshaft bearing allowed mainshaft to have more shock loading, especially in 3rd, which probably caused some stress risers to start cracking right at the cutouts on the 3rd synchro cone, which eventually was able to get hammered out as it broke into bite sized chunks and got hammered through the gap. Any guesses as to how long that took to happen? Other thoughts?

Only other catastrophic failures I've seen are pretty normal IMO. swing axle side gears that tear at the weld from excess load/oil starvation, fulcrum/axle spade end wear, differential wear. Brass 1-2 shift forks that are broken because they were just under designed. Corroded cases. early 1st gear with thin synchro hub thats been mushroomed over from overloading and worn/broken synchros.

Anyone else seen anything weird? I want to learn more.

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Catastrophic Failures

It sounds as though the mainshaft bearing wasn't retained by the nose cone. I like using steel bearing retaining plates on these early transaxles.

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

-

nshaddox

- Posts: 38

- Joined: Tue Jul 21, 2009 9:03 am

Re: Catastrophic Failures

thats what is weird though, outer race and inner race of mainshaft bearing were in correct location, just no cage around the balls. it did have a later 3 bolt nosecone on it, which I didn't think to look at closely but I am not sure how compatible those are with early style intermediate housings? but 3-4 clutch hub, 4th gear bearing race, inner race of mainshaft bearing were all in the correct location, just the synchro for 3rd had escaped somehow. anyone else seen any escaped synchro rings during core teardowns?

-

Casting Timmy

- Posts: 167

- Joined: Sun Nov 17, 2013 6:42 pm

Re: Catastrophic Failures

Big nut pinion bearing

Inner race cracks first, seen one with it the race broken apart and the rollers turned sideways and ran flat on the sides. I guess this is a short course off road problem and people usually bring it as it won’t stay in second. Folts can pocket first gear to put in the swingaxle thrust washer again on top of the pinion bearing, be sure to buy a shortened race and bearing from him at the same time though.

091 Catch Keys break

The current fix a lot of people do is switching to the 002 style catch keys and synchros. I know Folts is wanting to test out some solid 091 catch keys, but I haven’t heard they’ve been machined yet. If that doesn’t pan out I would like to test out a rectangle cut out inserted and tacked into the key and then bend up the spring wire on the other end or sub an 002 one already bent. Interesting talking to Folts in that the short course guys usually kill the synchros and springs with one race, he’s making Liberty Face plate splined hubs so quick change out since they are jam shifting anyways. Alternately he’s also exploring the solid hardened catch keys as well.

002 Small Pinion Nut Area

The shim washers get pounded out over time, Weddle has hardened washers that they say don’t pound out like the stock ones. Typically I like third gear clip tight to keep it from having a run up room on those washers. I have seen one core that tore down with shammed out shim washers and a 1st gear race that was pounding into the bottom of the nut as well. The nut had a physical depression into it from the race. Most of this core was gone though as the late style 1st gear idler was smashed and rolled so bad I couldn’t get the synchro off of it and it no longer had the correct bore size as well.

Bus main case

The buggy guys like to power out of reverse, saw one where he broke the case where the idler shaft for reverse presses in and tore out anything and everything to do with reverse. Input shaft coupler and idler shaft gear had multiple teeth missing, the shaft being flexed broke the case and the bearing for the shaft, sliding reverse gear done as ruined teeth on 1-2 slider.

Gear Smearing

Seen a few boxes where all the gears including the ring and pinion have rub marks from lack of gear oil protection…..I guess never changing the gear oil from the 70’s factory fill and installing a HP power and dragging/ running it hard doesn’t work out well. Hahaha

Fourth Gear Area

See heat problems here with melting mainshaft bearing plastic as well as idler bearing plastic. Lots of polished roller areas on the mainshafts from sticking rollers. Seen a couple times of plastic raced idler bearings having the plastic spun out and the rollers loose and starting to get broken up come in.

On your original problem with the clip gone and everything gone on the back end of the mainshaft, I’m starting to wonder if the 2nd and 3rd gear driving of people does a lot of the in/out movement to help pop and the clip off. I think 4th puts a lot of the heat into the mainshaft bearing, but am starting to wonder if that damage comes from the lower gears as they would be more common for shock loading as well as pushing and pulling as well. Mainly wondering as they can shock more in the lower gears and on the highway they’re more cruising instead of playing with it.

Inner race cracks first, seen one with it the race broken apart and the rollers turned sideways and ran flat on the sides. I guess this is a short course off road problem and people usually bring it as it won’t stay in second. Folts can pocket first gear to put in the swingaxle thrust washer again on top of the pinion bearing, be sure to buy a shortened race and bearing from him at the same time though.

091 Catch Keys break

The current fix a lot of people do is switching to the 002 style catch keys and synchros. I know Folts is wanting to test out some solid 091 catch keys, but I haven’t heard they’ve been machined yet. If that doesn’t pan out I would like to test out a rectangle cut out inserted and tacked into the key and then bend up the spring wire on the other end or sub an 002 one already bent. Interesting talking to Folts in that the short course guys usually kill the synchros and springs with one race, he’s making Liberty Face plate splined hubs so quick change out since they are jam shifting anyways. Alternately he’s also exploring the solid hardened catch keys as well.

002 Small Pinion Nut Area

The shim washers get pounded out over time, Weddle has hardened washers that they say don’t pound out like the stock ones. Typically I like third gear clip tight to keep it from having a run up room on those washers. I have seen one core that tore down with shammed out shim washers and a 1st gear race that was pounding into the bottom of the nut as well. The nut had a physical depression into it from the race. Most of this core was gone though as the late style 1st gear idler was smashed and rolled so bad I couldn’t get the synchro off of it and it no longer had the correct bore size as well.

Bus main case

The buggy guys like to power out of reverse, saw one where he broke the case where the idler shaft for reverse presses in and tore out anything and everything to do with reverse. Input shaft coupler and idler shaft gear had multiple teeth missing, the shaft being flexed broke the case and the bearing for the shaft, sliding reverse gear done as ruined teeth on 1-2 slider.

Gear Smearing

Seen a few boxes where all the gears including the ring and pinion have rub marks from lack of gear oil protection…..I guess never changing the gear oil from the 70’s factory fill and installing a HP power and dragging/ running it hard doesn’t work out well. Hahaha

Fourth Gear Area

See heat problems here with melting mainshaft bearing plastic as well as idler bearing plastic. Lots of polished roller areas on the mainshafts from sticking rollers. Seen a couple times of plastic raced idler bearings having the plastic spun out and the rollers loose and starting to get broken up come in.

On your original problem with the clip gone and everything gone on the back end of the mainshaft, I’m starting to wonder if the 2nd and 3rd gear driving of people does a lot of the in/out movement to help pop and the clip off. I think 4th puts a lot of the heat into the mainshaft bearing, but am starting to wonder if that damage comes from the lower gears as they would be more common for shock loading as well as pushing and pulling as well. Mainly wondering as they can shock more in the lower gears and on the highway they’re more cruising instead of playing with it.

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Catastrophic Failures

This could be a pretty fun thread if it had photos ..

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

-

Casting Timmy

- Posts: 167

- Joined: Sun Nov 17, 2013 6:42 pm

Re: Catastrophic Failures

Here's the pinion bearing failure, he brought it in as reverse wasn't working. It had been making noise for a bit, but he was still driving it with the noise.

Here's the bad 091 reverse, ruined a steel sleeved case.

Here's the bad 091 reverse, ruined a steel sleeved case.

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Catastrophic Failures

GREAT shots, Timmy. I can't say that I've ever seen such a dramatic failure of that bearing.

When VW changed to different sized rollers on either side and eliminated the thrust washer, problems began .. especially in off-road racing.

It's said that ultra slippery synthetic gear lubes can cause rollers to "skid" instead of roll. (I've seen this on the mainshaft needle bearing in later model waterboxers, due to their smaller diameter needles.)

Regarding the overheated 4th gears & needle bearings, this is usually attributable to low oil level in street cars, but when found in a heavy vanagon with powerful conversion engine, it's usually from an "overworked 4th gear".

Back in the old days with Type I-based road racing transaxles, we'd recirculate & cool the oil, dumping it back in on 4th gear (where the upper plug is):

With the overpowered Syncro Vanagons, we do something similar (oil pumped in from behind the little aluminum plate):

When VW changed to different sized rollers on either side and eliminated the thrust washer, problems began .. especially in off-road racing.

It's said that ultra slippery synthetic gear lubes can cause rollers to "skid" instead of roll. (I've seen this on the mainshaft needle bearing in later model waterboxers, due to their smaller diameter needles.)

Regarding the overheated 4th gears & needle bearings, this is usually attributable to low oil level in street cars, but when found in a heavy vanagon with powerful conversion engine, it's usually from an "overworked 4th gear".

Back in the old days with Type I-based road racing transaxles, we'd recirculate & cool the oil, dumping it back in on 4th gear (where the upper plug is):

With the overpowered Syncro Vanagons, we do something similar (oil pumped in from behind the little aluminum plate):

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

-

nshaddox

- Posts: 38

- Joined: Tue Jul 21, 2009 9:03 am

Re: Catastrophic Failures

I still have some of the destructed bits from the core I was talking about. I'll take some pics and post them up later this week. Pretty epic pinion bearing failure shot! Thanks for sharing.

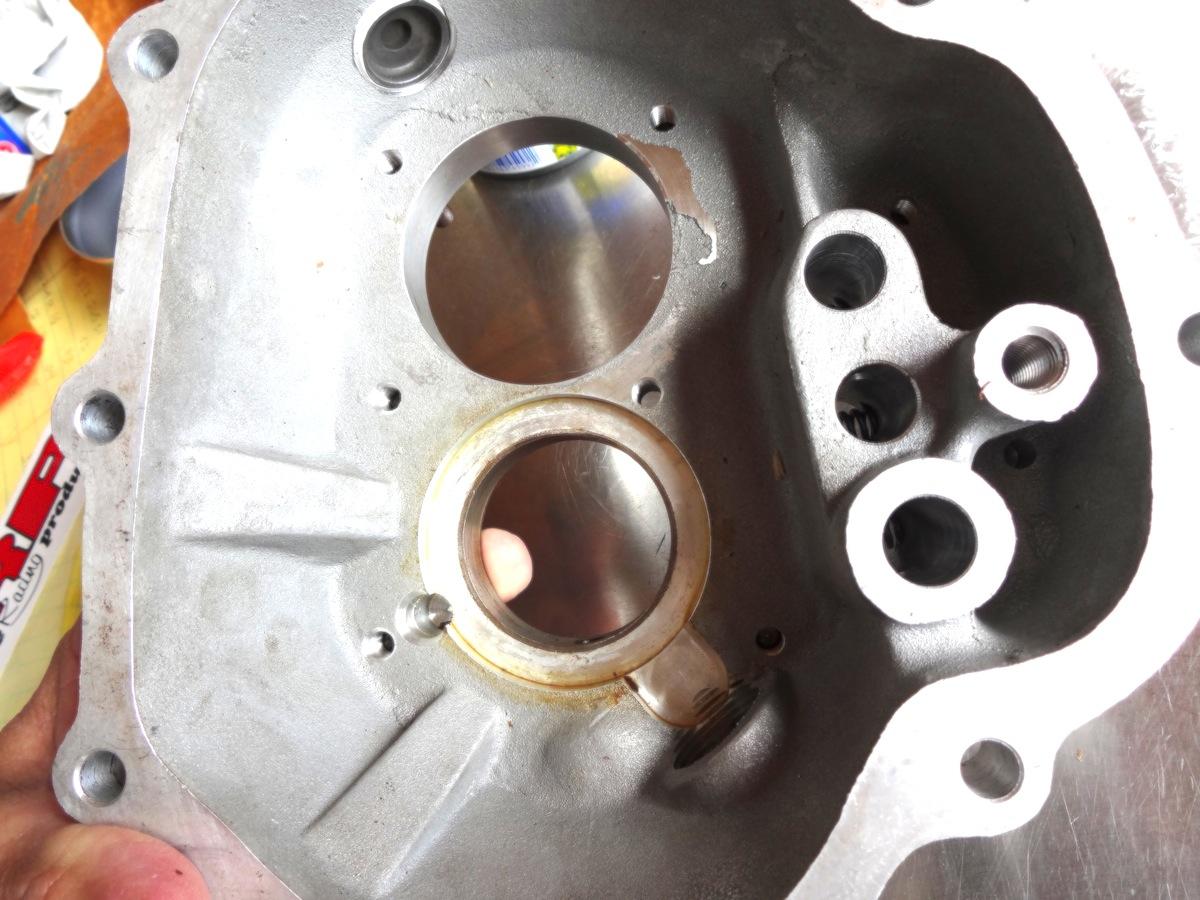

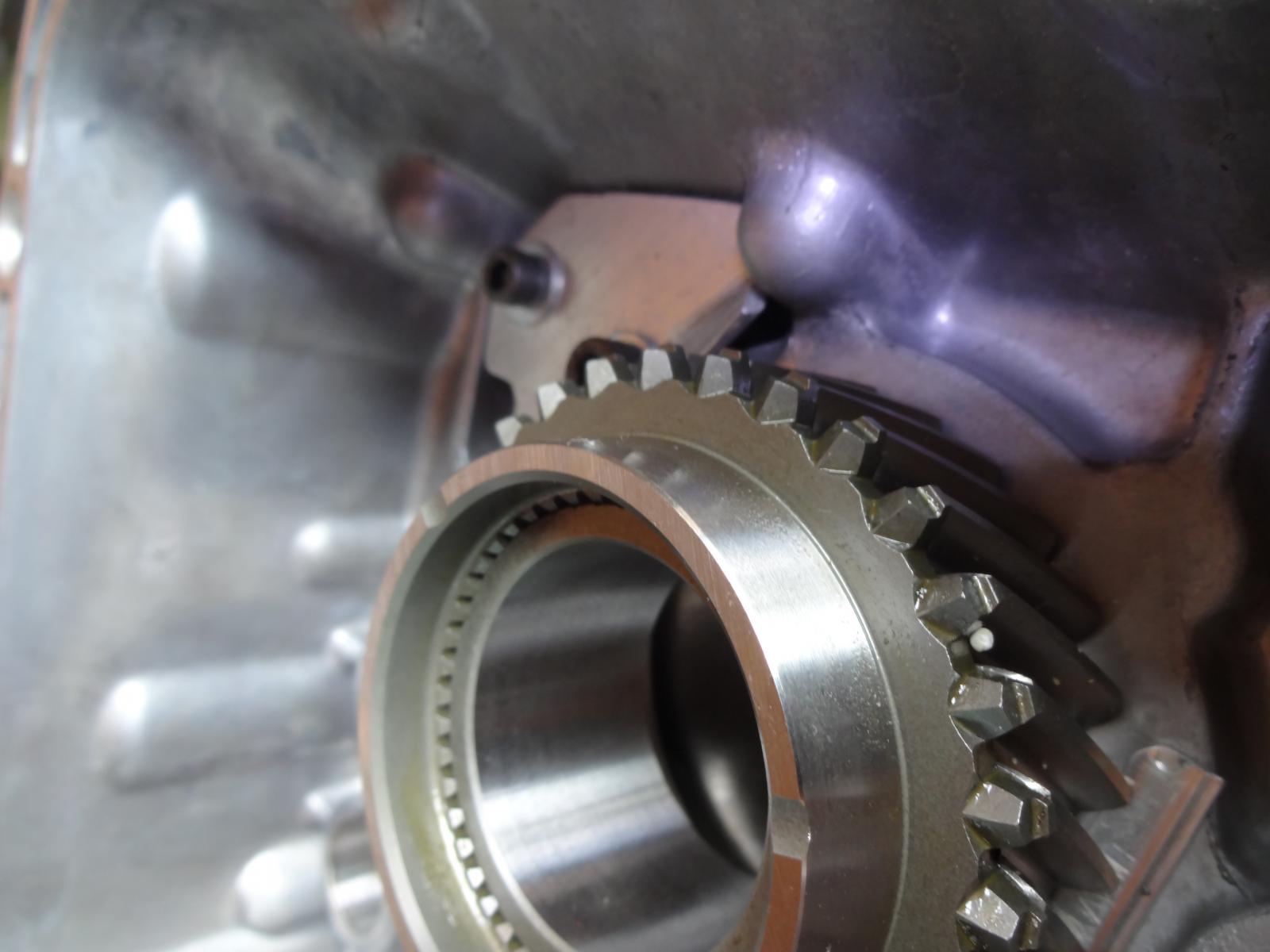

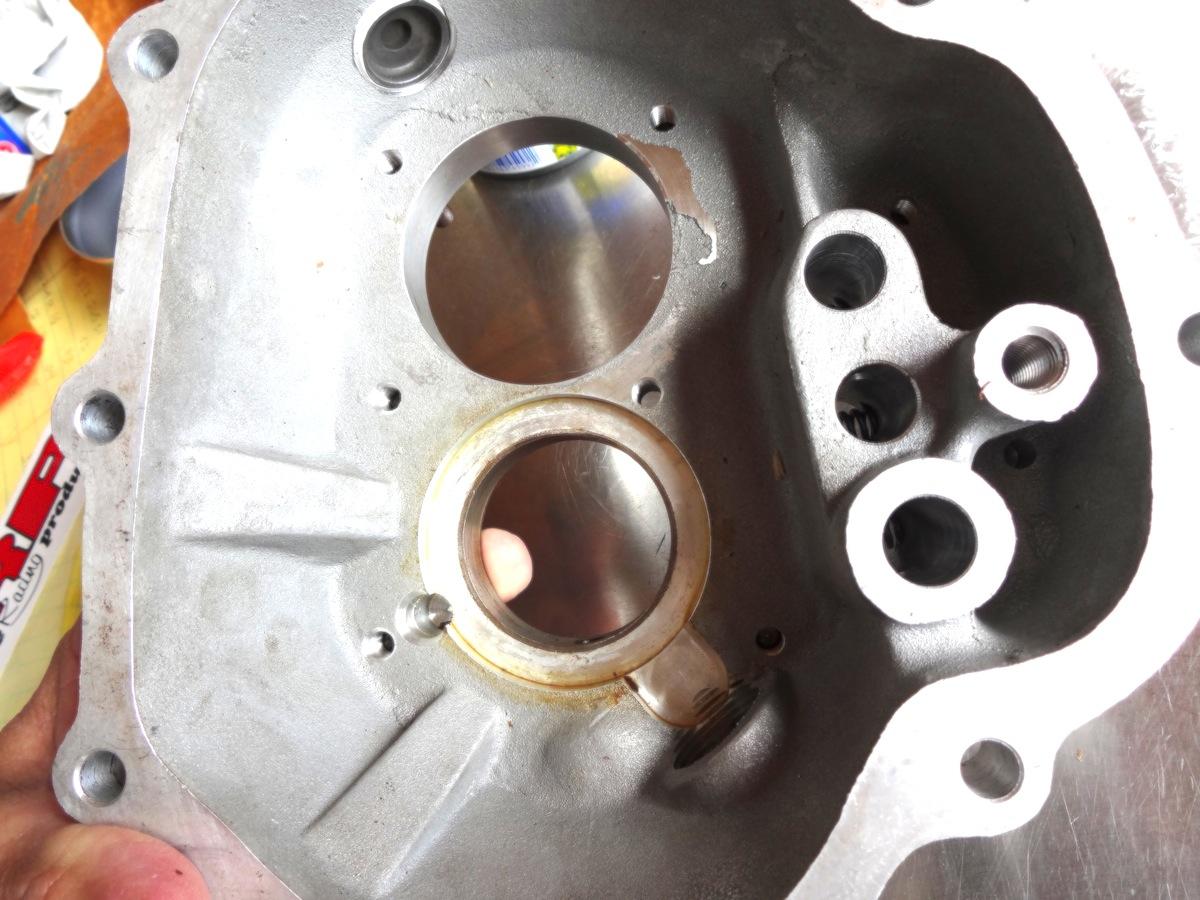

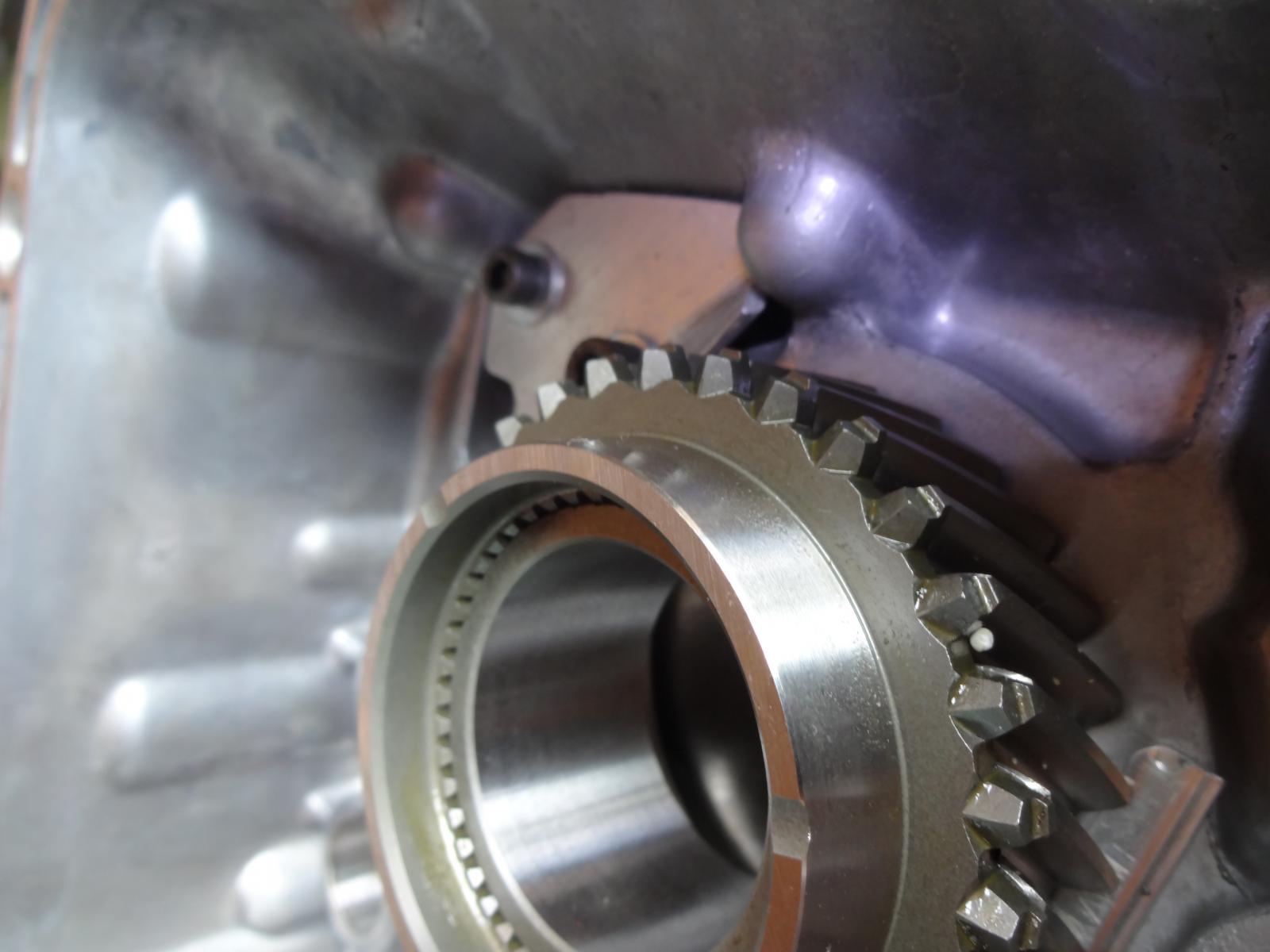

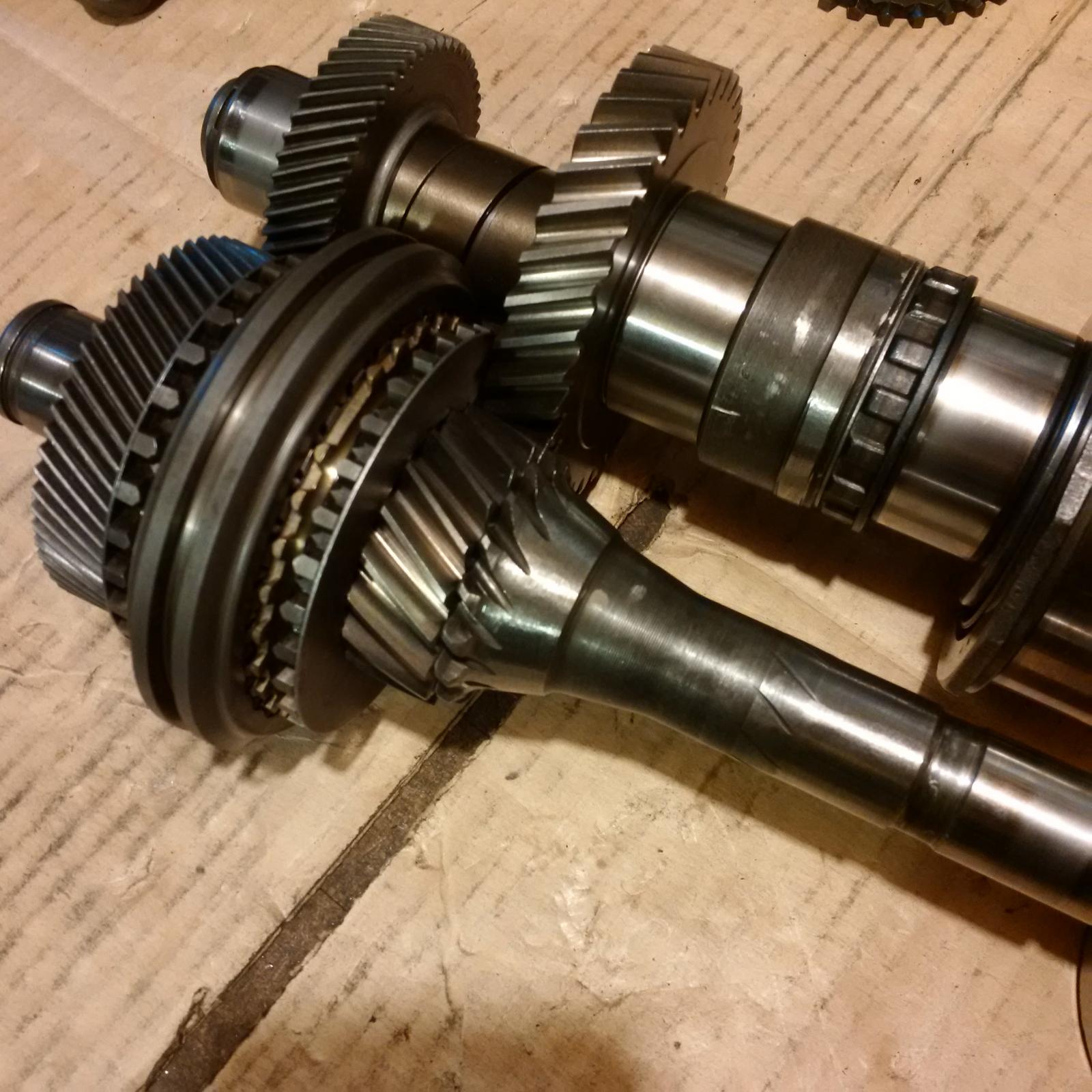

here are some pictures of the bits that came out of the core I described above.

3rd synchro exploded and made its way out of being trapped between the 3-4 hub and 3rd gear. 3-4 hub is somewhat dished on one side of the flat just out from the ID. slider didn't seem to have much damage but I'm still throwing it in the scrap bin. 2nd gear on mainshaft got chipped up pretty well. synchro cones on 3rd and 4th are both kinda chewed up (4th synchro ring was still in place.) one of the springs that hold the 3 little slider keys in place was in 2 pcs, but not pictured. teeth on 4th were kinda rolled over just on the other side of the synchro ring.

here are some pictures of the bits that came out of the core I described above.

3rd synchro exploded and made its way out of being trapped between the 3-4 hub and 3rd gear. 3-4 hub is somewhat dished on one side of the flat just out from the ID. slider didn't seem to have much damage but I'm still throwing it in the scrap bin. 2nd gear on mainshaft got chipped up pretty well. synchro cones on 3rd and 4th are both kinda chewed up (4th synchro ring was still in place.) one of the springs that hold the 3 little slider keys in place was in 2 pcs, but not pictured. teeth on 4th were kinda rolled over just on the other side of the synchro ring.

-

nshaddox

- Posts: 38

- Joined: Tue Jul 21, 2009 9:03 am

Re: Catastrophic Failures

another fun one from a recent core tear down. I've never seen a more completely stripped 1st gear. 3 piece spider shaft also interesting. what came first, chicken or the egg?

-

Bruce2

- Posts: 7087

- Joined: Sat Oct 13, 2001 1:01 am

Re: Catastrophic Failures

I had a mainshaft like that, and re-used it!

This was for a custom 2 speed trans for an electric car.

This was for a custom 2 speed trans for an electric car.One trans I took apart was full of busted parts. The reason it was taken out was for a stripped reverse gear. I suspect it was built with one of the notorious soft idler gears VW made.

But that wasn't all. Second gear synchro was broken into two pieces, but they stayed where they lived, unlike Neil's.

The 1-2 fork had the tip nearest the shift rod broken off like we've all seen many times, although this was on a factory steel fork!

When I pressed off the pinion bearing, one inner race was split.

I think there may have been more, I just don't recall right now.

You might be thinking that it takes a special type of idiot to cause that much carnage in one gearbox. That would be me!