Cutting late dual spring plates down to single?

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Cutting late dual spring plates down to single?

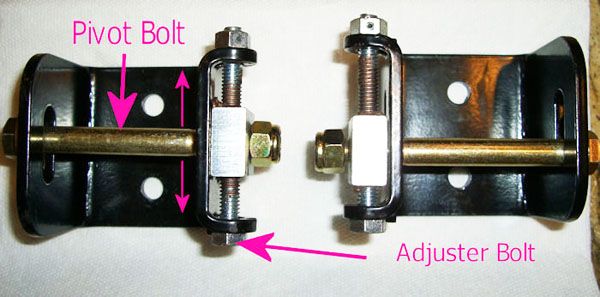

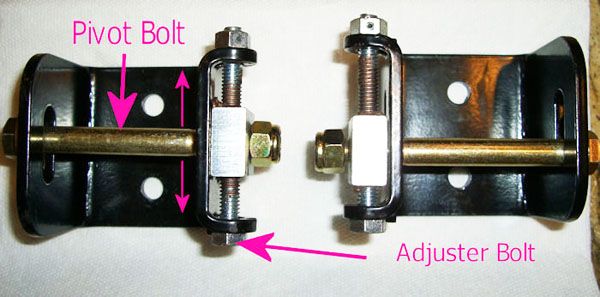

I have found what I consider nice design for a rear camber adjustable inner trailing mount for cars without frame horns, or with tubular frame horns, with a floating nutplate it could work with frame horns.

A fellow makes a version for TR6s, I'm going to try and convince him to make a version for T3s and T1s/rails etc. once I can provide a set as a pattern.

Goodparts.com makes/sells the TR6 bits, but this has much better pictures:

http://tr6.danielsonfamily.org/TrailingArmKit.htm

What do you think? Is the lift fork//jackscrew setup used on the 930 previously shown a better design?

You could probably mod the stock pickups for +/- 1/2" or so of adjustment in place, may prove sufficient and easier. (but not on a car with framehorns without major surgery for the inner nut)

Modding the existing pickup eliminates needing jigs for setting the distance from the springplate.

As all this kinda diverges from the initial point thread, should I start another on the (easy) fully adjustable rear suspension or keep it in this thread?

I also have an idea for an easier toe adjustment setup with jackscrews and maintaining springplate<>trailing arm rotational alignment, as the point is keeping caster and toe independently adjustable.

This would work using the original springplates or aftermarket, and allow fine adjustment without disassembly, just loosen the clamp bolts, adjust to taste, then reclamp.

This also would not get in the way of big fat rear tires.

SACO/German Auto doesn't seem to ship parts very fast, or at least they don't do email well, after 48 hours I only have an automated response to the order, and no response to further inquiries I made. They do have some interesting stuff I haven't seen elsewhere.

A fellow makes a version for TR6s, I'm going to try and convince him to make a version for T3s and T1s/rails etc. once I can provide a set as a pattern.

Goodparts.com makes/sells the TR6 bits, but this has much better pictures:

http://tr6.danielsonfamily.org/TrailingArmKit.htm

What do you think? Is the lift fork//jackscrew setup used on the 930 previously shown a better design?

You could probably mod the stock pickups for +/- 1/2" or so of adjustment in place, may prove sufficient and easier. (but not on a car with framehorns without major surgery for the inner nut)

Modding the existing pickup eliminates needing jigs for setting the distance from the springplate.

As all this kinda diverges from the initial point thread, should I start another on the (easy) fully adjustable rear suspension or keep it in this thread?

I also have an idea for an easier toe adjustment setup with jackscrews and maintaining springplate<>trailing arm rotational alignment, as the point is keeping caster and toe independently adjustable.

This would work using the original springplates or aftermarket, and allow fine adjustment without disassembly, just loosen the clamp bolts, adjust to taste, then reclamp.

This also would not get in the way of big fat rear tires.

SACO/German Auto doesn't seem to ship parts very fast, or at least they don't do email well, after 48 hours I only have an automated response to the order, and no response to further inquiries I made. They do have some interesting stuff I haven't seen elsewhere.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Cutting late dual spring plates down to single?

I pretty sure understand what it being done and the basic idea might have some promise... with changes.

In my opinion:

At a minimum, there needs to be a second sliding adjuster on the other side of the pivot bolt. You have the potential of tipping/bending the pivot bolt in the slot, with no additional support for the bolt which could change the trailing arm's geometry... if it does. Just pinching things together isn't always the best way.

I also think I would also want a different bolt design. The original designers used a shoulder bolt as a pivot not a straight bolt. There has to be a reason why they did it that way! On a shoulder bolt the threaded end usually doesn't have any support responsibilities (you don't put threads in shear) other than clamping.

If you were playing with something like this I think I would be more inclined to agree assuming the second sliding adjuster was added.

Lee

My opinion is worth quite a bit less than you paid for it.

In my opinion:

At a minimum, there needs to be a second sliding adjuster on the other side of the pivot bolt. You have the potential of tipping/bending the pivot bolt in the slot, with no additional support for the bolt which could change the trailing arm's geometry... if it does. Just pinching things together isn't always the best way.

I also think I would also want a different bolt design. The original designers used a shoulder bolt as a pivot not a straight bolt. There has to be a reason why they did it that way! On a shoulder bolt the threaded end usually doesn't have any support responsibilities (you don't put threads in shear) other than clamping.

If you were playing with something like this I think I would be more inclined to agree assuming the second sliding adjuster was added.

Lee

My opinion is worth quite a bit less than you paid for it.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Cutting late dual spring plates down to single?

Actually that bolt is NOT technically under shear on aftermarket setups: it clamps a steel tube the bushings ride on to the mount.

The STOCK bolt is under SINGLE shear, with the bolt head protrucing through a hole with some slop...

...but the adjustable ones pictured are not, they use a through bolt, so the center tube is sandwiched and takes the load.

There are (or will be) washers on both ends of the tube, but the tube will take the actual load.

As there is ~zero play in the urethane or delrin bushings, the adjuster on just one side works: The arm keeps things straight.

May be easier to do the fork with jackscrew setup as gravity will pull it back down, and it reduces the parts count.

We'll see how it ends up this weekend. 70F and sunny, and is finally dried out.

The STOCK bolt is under SINGLE shear, with the bolt head protrucing through a hole with some slop...

...but the adjustable ones pictured are not, they use a through bolt, so the center tube is sandwiched and takes the load.

There are (or will be) washers on both ends of the tube, but the tube will take the actual load.

As there is ~zero play in the urethane or delrin bushings, the adjuster on just one side works: The arm keeps things straight.

May be easier to do the fork with jackscrew setup as gravity will pull it back down, and it reduces the parts count.

We'll see how it ends up this weekend. 70F and sunny, and is finally dried out.

Last edited by Piledriver on Thu Jan 28, 2016 3:16 pm, edited 1 time in total.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Cutting late dual spring plates down to single?

Pile, with the slot instead of a hole, is not really doing what you think; a slot could be thought of an open hole on two sides. That side of the bracket is free rather than being captured like the other side. Slots have their place but in this case I think the idea needs some changes mostly an identical situation on the opposite side of the bracket. I think the spring plates, if you are still going to use them, also can exacerbate the situation.

Again, my opinion based on what I did in engineering (I'm not an engineer but a tech); not the same situation but the discussions on them somewhat covered this in my opinion.

Lee

Again, my opinion based on what I did in engineering (I'm not an engineer but a tech); not the same situation but the discussions on them somewhat covered this in my opinion.

Lee

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Cutting late dual spring plates down to single?

There will be large hardened washers on both sides of the tube to spread the load.

VW used a single shear bolt, and they are not known for failures other than backing out and disappearing.

I suspect it will be far more than sufficient.

The easiest way to do this and what i originally proposed is making the mount on the torsion tube a flat plate and weld a matching flat plate on the actual arm pivot mount, with slotted holes to allow adjustment.

For most of us that would work fine, will be a one time adjustment.

... but racers would likely want fine adjustment on a regular basis to suit the track/conditions.

VW used a single shear bolt, and they are not known for failures other than backing out and disappearing.

I suspect it will be far more than sufficient.

The easiest way to do this and what i originally proposed is making the mount on the torsion tube a flat plate and weld a matching flat plate on the actual arm pivot mount, with slotted holes to allow adjustment.

For most of us that would work fine, will be a one time adjustment.

... but racers would likely want fine adjustment on a regular basis to suit the track/conditions.

Last edited by Piledriver on Thu Jan 28, 2016 3:23 pm, edited 1 time in total.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Cutting late dual spring plates down to single?

You asked for an opinion so I gave it to you. I hope I am wrong. Lee

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Cutting late dual spring plates down to single?

I appreciate the feedback, just trying to explain the idea better.Ol'fogasaurus wrote:You asked for an opinion so I gave it to you. I hope I am wrong. Lee

Do you have any ideas on an alternative way to design an adjustable mount not using slots?

Perhaps one that pivots?

Note any forward or aft movement (like with an eccentric bolt) is undesirable as it changes toe and track as well as caster.

I considered a series of holes, but a 7/8" bolt does not allow fine adjustments.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Cutting late dual spring plates down to single?

I am going to back off on this. When I opened up the URL I saw something entirely different that what I saw a minute ago. What is shown there might work but it is definitely not what I was reacting to.

Lee

Which of these are we talking about.

#1 which is not what I was talking about.

This is the what I was talking about.

Lee

Which of these are we talking about.

#1 which is not what I was talking about.

This is the what I was talking about.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Cutting late dual spring plates down to single?

An eccentric bolt is an awesome idea in some applications...

This is absolutely not one of those.

The problem is, at the inner IRS bushing, an eccentric pivot bolt manages to change toe, camber and track width all in one motion,

... which makes it an exceptionally bad idea if you are trying to actually adjust your suspension in some specific direction.

That's why I discounted the idea of the eccentric, and pursued the conventional slotted adjuster as used on many, many race cars over the years.

The adjustable setup would be for street/AX/road racing, not off road abuse.

On an off road rig it would be best to have a movable mount secured to the torsion with multiple bolts as originally proposed, set camber as desired, and once satisfied with the setup weld it in place.

I may end up doing that myself in the end.

This is absolutely not one of those.

The problem is, at the inner IRS bushing, an eccentric pivot bolt manages to change toe, camber and track width all in one motion,

... which makes it an exceptionally bad idea if you are trying to actually adjust your suspension in some specific direction.

That's why I discounted the idea of the eccentric, and pursued the conventional slotted adjuster as used on many, many race cars over the years.

The adjustable setup would be for street/AX/road racing, not off road abuse.

On an off road rig it would be best to have a movable mount secured to the torsion with multiple bolts as originally proposed, set camber as desired, and once satisfied with the setup weld it in place.

I may end up doing that myself in the end.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Ol'fogasaurus

- Posts: 17758

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Cutting late dual spring plates down to single?

Pile, I think I like the basic concept of the adjustable rig but it is not finished in my opinion. I think there is a lot more that has to be considered to make it a good option. (Photo Bucket is also down so I can't get pictures.) I had several feet of dialogue and pictures done last night before I went back and checked the URLs which got me confused to what was being talked about.

I have a busy day today: I have some work to get to in the pottery shop (pottery club's area) then at ~4:00 pm tonight we are hosting the weekly get-together of people from a couple of streets. Anywhere from 20 to 50+ people can attend.

This last bit/URL on the adjustable pivots has got me thinking; I would like to explain what, why and maybe clear up what I have said before. One of the things I did at work is not always give a complete answer but enough to get the person enough tease to get them thinking the problem out. If you give a complete answer then they go away fat happy but probably haven't learned anything plus they probably haven't reasoned anything out. My job was to mentor and teach. As a kid I was brought up this way (my father was an electrical engineer); when I started working in engineering the same thing was done to me. It has turned out that after all the years of working like this I am still in the habit which is why you (metaphoric you) often get incomplete or vailed answers. Sorry guys!

I can either PM you or if people want to see it I can do it here. It might be somewhat long and dry so I am asking what you want. At best it would be late tonight or tomorrow.

Lee

I have a busy day today: I have some work to get to in the pottery shop (pottery club's area) then at ~4:00 pm tonight we are hosting the weekly get-together of people from a couple of streets. Anywhere from 20 to 50+ people can attend.

This last bit/URL on the adjustable pivots has got me thinking; I would like to explain what, why and maybe clear up what I have said before. One of the things I did at work is not always give a complete answer but enough to get the person enough tease to get them thinking the problem out. If you give a complete answer then they go away fat happy but probably haven't learned anything plus they probably haven't reasoned anything out. My job was to mentor and teach. As a kid I was brought up this way (my father was an electrical engineer); when I started working in engineering the same thing was done to me. It has turned out that after all the years of working like this I am still in the habit which is why you (metaphoric you) often get incomplete or vailed answers. Sorry guys!

I can either PM you or if people want to see it I can do it here. It might be somewhat long and dry so I am asking what you want. At best it would be late tonight or tomorrow.

Lee

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Cutting late dual spring plates down to single?

Hi Piledriver,

I think you had this figured out in your very first post. You need single spring plates, rolled fenders, and trimmed bolt heads.

Dual spring plates were originally T3 parts, in anticipation of heaver loads. I personally love them. For racing (with the right bushings), they make the rear diagonal arm and spring plate a very rigid assembly and reduce toe-in and toe-out deflection to nil. That means no self-steering from the rear.

Now, if dual spring plates were so good, why didn't Porsche use them on the 911/912? Because Porsche stuck to their accumulated experience in spring plates that were supplemental springs in and of themselves. They twist on acceleration squat, and toe-in the rear, adding stability, and in a hard corner, make the loaded rear wheel toe-in, and adds some self-steering, improving "turn in" feel.

But there comes a point in increased speed where you don't want any self-steering, and some 911 racers began to try ways to stiffen the spring plates. Finally, Porsche did away with the whole four-joint, diagonal trailing arm, torsion bar rear suspension.

The worst that can happen to you with single spring plates is more sway and self steering if you really, really took it to the limit.

FJC

I think you had this figured out in your very first post. You need single spring plates, rolled fenders, and trimmed bolt heads.

Dual spring plates were originally T3 parts, in anticipation of heaver loads. I personally love them. For racing (with the right bushings), they make the rear diagonal arm and spring plate a very rigid assembly and reduce toe-in and toe-out deflection to nil. That means no self-steering from the rear.

Now, if dual spring plates were so good, why didn't Porsche use them on the 911/912? Because Porsche stuck to their accumulated experience in spring plates that were supplemental springs in and of themselves. They twist on acceleration squat, and toe-in the rear, adding stability, and in a hard corner, make the loaded rear wheel toe-in, and adds some self-steering, improving "turn in" feel.

But there comes a point in increased speed where you don't want any self-steering, and some 911 racers began to try ways to stiffen the spring plates. Finally, Porsche did away with the whole four-joint, diagonal trailing arm, torsion bar rear suspension.

The worst that can happen to you with single spring plates is more sway and self steering if you really, really took it to the limit.

FJC

-

Steve Arndt

- Posts: 7404

- Joined: Sat Mar 10, 2001 12:01 am

Re: Cutting late dual spring plates down to single?

You will get ~ twice as much up/down movement as you do front/back movement with the eccentric bolt when it is centered in its arc. Trig. I think it is a fine solution. I doubt our cars are within a couple milimeters of square and equal wheelbase on each corner anyway.

Steve

My Baja Build

My Baja Build

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Cutting late dual spring plates down to single?

Thanks for popping in FJCamper, have any comments on the adjustable inner trailing arm pickup?

I'm hoping a better, proven design will appear as if by magic.

Also, any experience with Bilstein SG series shocks?

36mm//1-5/8" body size, same diameter as Monroes, except single tube gas and coil over ready, and orderable in a huge array of damping settings? 6", 7" and 8" stroke available. (stock is ~6")

I have seen them for ~70ish$

I also finally noticed that the T3 rear shock upper mount is double shear from the factory, so as far as I can see T3s are almost coil over ready out back.

**********************

Got after it playing with my still in work front hubs, those factory discs were very thick at the wheel face, so I think I'll just pop studs in.

If I trimmed off the existing caliper mount, I suspect they would work with NO spacers, but whats going to work best is still up in the air, I'm not going to cut off the mount on my existing late T3 calipers, but I do have a spare set of earlies that mostly only differ in the caliper mount, and I would have zero moral issues modding those, plus I can play with the setup on the bench rather than on the car.

Also the caliper mount offset works with either 15mm or 1" spacer under the hats, 1" puts caliper mount axial postion in same plane as the face of the steering knuckle spindle face, and 15mm puts the caliper mount in ~the same plane and location as the existing caliper mount, I could put one bolt in if I drilled the calipers for the bigger bolt. (bolt spacing is wider though...

The steel hats sadly only come in 3" offset, its ~3.5" with the rotor and std bolts attached on the backside.

The spacer used would just need a tiny bit of weld and trued up on the lathe to center the hats.

Fills the wheelwell nice, the scrub radius is increased a tad but no more than a T1 with Empi 8 spokes.

*******************

On the rear, 30 seconds with a cutoff and now I have single spring plates.

With the 15mm spacer, tons of room, but of course ...(purely as an exercise )

)

...I decided to see what hits with NO spacers...

The front of the trailing arm blade hits the fattest part of the sidewall.

I could trim it back to just past the (currently empty) 4th bolt hole keeping the 4th hole, that arc would just about line up with the rim edge, spring plate clearance still ~10mm, and nothing else other than the spring plate stop is close.

Managed to kill my 10+ year old HF 4" grinder, blade got pinched and it overtightedn the nut, the silly shaft lock broke getting it apart, looks fixable, but I see a new one in my future.

************************

I played with the alleged factory "camber/toe adjustment":

Keeping toe and ride height constant, the camber adjustment range was almost in measurement noise as measured using either of my digital levels/protractors (Bosch and HF) both only .1 degree precision, but the amount of adjustment range I see is ~useless so I'll be proceeding with the inner pickup mod of some sort.

I'm wondering if 7mm on Marcos eccentric bolt is enough range... Probably as I'm not dropping it much lower than it is, maybe 2" total from the originally quite high ride height.

*************

Still not a peep from SACO or Wilwood, I guess they don't respond to emails well, even from paying customers.

Still no shipping confirmation from SACO after 4 days, paid via paypal on the spot.

I was hoping to have those delrin bushings to install with the rear all apart this weekend.

I'm hoping a better, proven design will appear as if by magic.

Also, any experience with Bilstein SG series shocks?

36mm//1-5/8" body size, same diameter as Monroes, except single tube gas and coil over ready, and orderable in a huge array of damping settings? 6", 7" and 8" stroke available. (stock is ~6")

I have seen them for ~70ish$

I also finally noticed that the T3 rear shock upper mount is double shear from the factory, so as far as I can see T3s are almost coil over ready out back.

**********************

Got after it playing with my still in work front hubs, those factory discs were very thick at the wheel face, so I think I'll just pop studs in.

If I trimmed off the existing caliper mount, I suspect they would work with NO spacers, but whats going to work best is still up in the air, I'm not going to cut off the mount on my existing late T3 calipers, but I do have a spare set of earlies that mostly only differ in the caliper mount, and I would have zero moral issues modding those, plus I can play with the setup on the bench rather than on the car.

Also the caliper mount offset works with either 15mm or 1" spacer under the hats, 1" puts caliper mount axial postion in same plane as the face of the steering knuckle spindle face, and 15mm puts the caliper mount in ~the same plane and location as the existing caliper mount, I could put one bolt in if I drilled the calipers for the bigger bolt. (bolt spacing is wider though...

The steel hats sadly only come in 3" offset, its ~3.5" with the rotor and std bolts attached on the backside.

The spacer used would just need a tiny bit of weld and trued up on the lathe to center the hats.

Fills the wheelwell nice, the scrub radius is increased a tad but no more than a T1 with Empi 8 spokes.

*******************

On the rear, 30 seconds with a cutoff and now I have single spring plates.

With the 15mm spacer, tons of room, but of course ...(purely as an exercise

...I decided to see what hits with NO spacers...

The front of the trailing arm blade hits the fattest part of the sidewall.

I could trim it back to just past the (currently empty) 4th bolt hole keeping the 4th hole, that arc would just about line up with the rim edge, spring plate clearance still ~10mm, and nothing else other than the spring plate stop is close.

Managed to kill my 10+ year old HF 4" grinder, blade got pinched and it overtightedn the nut, the silly shaft lock broke getting it apart, looks fixable, but I see a new one in my future.

************************

I played with the alleged factory "camber/toe adjustment":

Keeping toe and ride height constant, the camber adjustment range was almost in measurement noise as measured using either of my digital levels/protractors (Bosch and HF) both only .1 degree precision, but the amount of adjustment range I see is ~useless so I'll be proceeding with the inner pickup mod of some sort.

I'm wondering if 7mm on Marcos eccentric bolt is enough range... Probably as I'm not dropping it much lower than it is, maybe 2" total from the originally quite high ride height.

*************

Still not a peep from SACO or Wilwood, I guess they don't respond to emails well, even from paying customers.

Still no shipping confirmation from SACO after 4 days, paid via paypal on the spot.

I was hoping to have those delrin bushings to install with the rear all apart this weekend.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Cutting late dual spring plates down to single?

Hi Piledriver,

The adjusters you pictured look good, making my gut appraisal of them a "maybe."

When you are working with suspension fulcrum points, the rule of thumb is to do as little as possible. The book that comes closest to addressing your questions is the "Porsche 911 Performance Handbook" by Bruce Anderson. He shows a whole string of factory and modified rear diagonal arm assemblies and altered pickup points in the evolving quest to improve handling.You might say, "Well, I'm just trying to make some tire room and be able to adjust my camber and toe."

You and a thousand other 911 guys.

No one fix ever became a standard because the 911's kept evolving. The common VW-Porsche problem is we have a rear engine and suspension loads are severe in the rear, causing self steering as bushings deflect. More people have tried various design forward pickup point camber/toe adjusters with success than other designs. You loosen the spring plate bolts, and twist the concentric in the forward pickup point, and it rotates the arm upward and inward, or downward and outward.

The wider the tire, the closer to zero camber and zero toe you want.

To close here, back tracking to the rear-engine problem. While Mercedes chose the semi-trailing arm arrangement at the rear because it has almost zero self-steering, Porsche (& VW) used trailing arms, with self-steering, and to a very satisfactory degree of success made the self steering wotk for, not against, the driver.

FJC.

The adjusters you pictured look good, making my gut appraisal of them a "maybe."

When you are working with suspension fulcrum points, the rule of thumb is to do as little as possible. The book that comes closest to addressing your questions is the "Porsche 911 Performance Handbook" by Bruce Anderson. He shows a whole string of factory and modified rear diagonal arm assemblies and altered pickup points in the evolving quest to improve handling.You might say, "Well, I'm just trying to make some tire room and be able to adjust my camber and toe."

You and a thousand other 911 guys.

No one fix ever became a standard because the 911's kept evolving. The common VW-Porsche problem is we have a rear engine and suspension loads are severe in the rear, causing self steering as bushings deflect. More people have tried various design forward pickup point camber/toe adjusters with success than other designs. You loosen the spring plate bolts, and twist the concentric in the forward pickup point, and it rotates the arm upward and inward, or downward and outward.

The wider the tire, the closer to zero camber and zero toe you want.

To close here, back tracking to the rear-engine problem. While Mercedes chose the semi-trailing arm arrangement at the rear because it has almost zero self-steering, Porsche (& VW) used trailing arms, with self-steering, and to a very satisfactory degree of success made the self steering wotk for, not against, the driver.

FJC.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Re: Cutting late dual spring plates down to single?

Thank you, sir.

I'm leaning towards cutting the existing mounts off leaving a bit of the base to align on, make up some side plates to weld/keep things straight and tack, raise pickup as needed to set camber at ~0 at desired ride height with stock "adjustment" at center of its range, and them box/reweld everything.

With the 15mm spacer I have tons of clearance, tried clearancing for no spacer and it just rubs on the shock mount vertical and the body side of the upper mount, neither would be an issue if camber was ~zeroed at ride height.

I'll need to pull the rear torsion to do this properly but it does unbolt, may even be able to pull it off with engine and trans in place.

Still curious about the Bilstein SG series 36mm coil over ready shocks, currently have the car set up with no torsion bars and using my 4 ways over Monroes as temporary substitutes... (don't plan on driving much more than around the block like that, as the clamp on mount wasn't designed to support a car)

At least I'll see if 400 lb/in springs are about right.

Still no delrin bushings or even a shipping confirmation from SACO-German after 5 days.

For the record, with no bar/shocks and greased urethane bushes, there is ~6 degrees of camber change on a T3 over full travel, hardstop to hardstop, with no bumpstop.

The stock camber "adjustment" in the 3 rear bolts only is ~1 degree limit to limit, keeping toe and ride height constant.

If you keep all 4 bolts in the springplate it's less, could not measure with 4th bolt as cutoff wheel made it go away.

I'm leaning towards cutting the existing mounts off leaving a bit of the base to align on, make up some side plates to weld/keep things straight and tack, raise pickup as needed to set camber at ~0 at desired ride height with stock "adjustment" at center of its range, and them box/reweld everything.

With the 15mm spacer I have tons of clearance, tried clearancing for no spacer and it just rubs on the shock mount vertical and the body side of the upper mount, neither would be an issue if camber was ~zeroed at ride height.

I'll need to pull the rear torsion to do this properly but it does unbolt, may even be able to pull it off with engine and trans in place.

Still curious about the Bilstein SG series 36mm coil over ready shocks, currently have the car set up with no torsion bars and using my 4 ways over Monroes as temporary substitutes... (don't plan on driving much more than around the block like that, as the clamp on mount wasn't designed to support a car)

At least I'll see if 400 lb/in springs are about right.

Still no delrin bushings or even a shipping confirmation from SACO-German after 5 days.

For the record, with no bar/shocks and greased urethane bushes, there is ~6 degrees of camber change on a T3 over full travel, hardstop to hardstop, with no bumpstop.

The stock camber "adjustment" in the 3 rear bolts only is ~1 degree limit to limit, keeping toe and ride height constant.

If you keep all 4 bolts in the springplate it's less, could not measure with 4th bolt as cutoff wheel made it go away.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.