Rear suspension, engine, and trans. bracing points

- Jadewombat

- Posts: 1447

- Joined: Sat Jun 22, 2002 12:01 am

Rear suspension, engine, and trans. bracing points

Saw this short youtube video on another forum. OK, a 911 GT3 has about as much in common with a bug that both have four wheels, rear-engined and both made by Dr. Porsche a long time ago. Still though, take a look at this video. I wouldn't want the task of removing/putting back this drivetrain, but it's very interesting to see the mounting and bracing points Porsche used on the GT3. As our cars are still being pushed hard and hp and trans. capacity keep increasing, there's more need to make sure everything in the back end of a bug or ghia (or T3) all works together to perform.

I would add I don't think the chapter has been written and finalized many years ago that the Kafer bar is the ONLY solution to transferring power to the ground/letting the shocks do most of the work. I'm not against Kafer bars, arguably, it's just not the single fix-all to rear engined air-cooled V-Dubs, IMHO.

http://forums.pelicanparts.com/porsche- ... d-68170821

I would add I don't think the chapter has been written and finalized many years ago that the Kafer bar is the ONLY solution to transferring power to the ground/letting the shocks do most of the work. I'm not against Kafer bars, arguably, it's just not the single fix-all to rear engined air-cooled V-Dubs, IMHO.

http://forums.pelicanparts.com/porsche- ... d-68170821

- ChadH

- Posts: 254

- Joined: Wed Mar 30, 2016 4:55 pm

Re: Rear suspension, engine, and trans. bracing points

After having just completed a clutch replacement on our '07 Mini Cooper S, I almost couldn't watch that. Getting the Mini trans out wasn't quite that bad, but it was close. Especially for 1 guy working off of the garage floor without a lift. I couldn't have done it without the great tech instructions the Pelican has on their web site.

Engine and suspension pick-up bracing is 80% of the reason for building a cage on my autocross project. At the end of the day (year?), the frame horns will be braced by what is essentially a Kafer bar though.

Engine and suspension pick-up bracing is 80% of the reason for building a cage on my autocross project. At the end of the day (year?), the frame horns will be braced by what is essentially a Kafer bar though.

- petew

- Posts: 3920

- Joined: Sat Oct 07, 2006 4:05 pm

Re: Rear suspension, engine, and trans. bracing points

It really isn't that hard to build budget Kafer bars that do largely the same thing. You don't need heims on the end of it. Looking at the those diagonal braces, they're all round bars with crushed ends. You can also add extra steel to the gearbox mount to stiff it up and stop it flexing like their cross brace. And that cars is putting out a LOT more torque than anything we drive.

Here's my kafer bar setup with a stiffened gearbox mount.

Here's my kafer bar setup with a stiffened gearbox mount.

- Jadewombat

- Posts: 1447

- Joined: Sat Jun 22, 2002 12:01 am

- ChadH

- Posts: 254

- Joined: Wed Mar 30, 2016 4:55 pm

Re: Rear suspension, engine, and trans. bracing points

I'm Collecting ideas for my build (when I eventually get time to get back on it..)

Do you have the upper end of the braces welded to the cross bar - or is there a bolt up there? It's hard to tell from the picture.

Is the cross bar welded directly to the body, or does it connect to something else? It doesn't look like it connects to the shock bolt like a typical bolt in.

Do you have the upper end of the braces welded to the cross bar - or is there a bolt up there? It's hard to tell from the picture.

Is the cross bar welded directly to the body, or does it connect to something else? It doesn't look like it connects to the shock bolt like a typical bolt in.

- petew

- Posts: 3920

- Joined: Sat Oct 07, 2006 4:05 pm

Re: Rear suspension, engine, and trans. bracing points

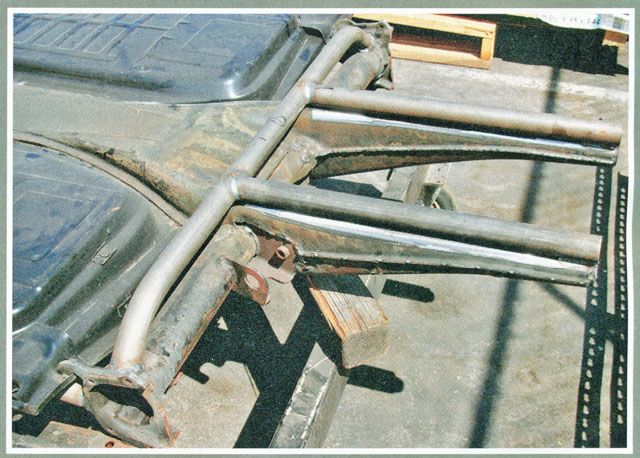

The cross bar bolts through the upper shock mounts and shocks... (before I added the diagonal braces)

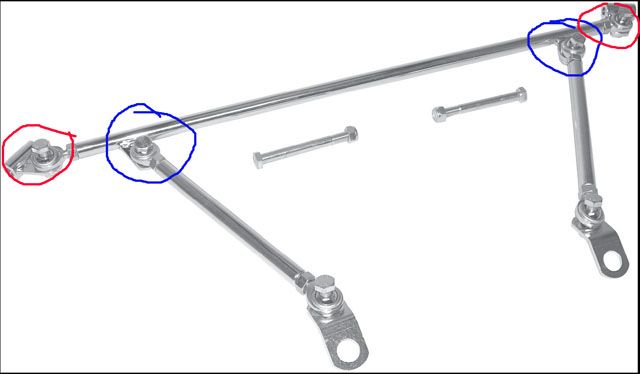

Diagonals bolt in too. Out of the car...

Diagonals bolt in too. Out of the car...

- ChadH

- Posts: 254

- Joined: Wed Mar 30, 2016 4:55 pm

Re: Rear suspension, engine, and trans. bracing points

Thank you. Those pictures clarify a lot. I'm guessing you have a threaded bung at the ends of the cross bar that the shock bolts bolt into? I just might steal some of your ideas here.

Maybe, if the planets align just right, I'll find some time this weekend to work rear horn bracing into my cage build.

Maybe, if the planets align just right, I'll find some time this weekend to work rear horn bracing into my cage build.

-

Ol'fogasaurus

- Posts: 17756

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Rear suspension, engine, and trans. bracing points

This is the Mendola Truss bar for IRS suspensions. Noticed that it connects to the trailing arm pivot for a pretty much fully locked suspension aid.

This is another style of truss bar but I do not like the join in the center of the top bar that goes between the shock mount bars. The join is a weak spot in my opinion.

This is a more normal Truss bar. The long bolts hold the top bar in place, go through the shocks then the shock mounts on the torsion bar. It would allow a cage to be added if that was your want.

This is the style I finally bought after a lot of self argument.

This is another way but I see way too many weaknesses here.

viewtopic.php?f=28&t=113703&start=465

Next to the bottom of the page is a picture showing a loosely put together commercial Kaffer bar I bought for my off-road glass buggy. It is currently also sitting loosely in place as it had to be there for the potential fitting of my fuel tank… yes or no in that same area but higher.

I hope this helps and gives you some ideas on what you want to do.

- ChadH

- Posts: 254

- Joined: Wed Mar 30, 2016 4:55 pm

Re: Rear suspension, engine, and trans. bracing points

That Mendola truss is very fancy. With mine, I'll tie the cross bar and shock mount area up to the cage, inside the cockpit, so I think the struts connecting to the trailing arm pivot would be redundant. I'm guessing the turnbuckles are only needed for a "bolt-in" installation, and to allow for dimensional variance between different cars. Being a cheapskate, I'll weld as much as possible, as long as I can still get the transmission out easily.

I agree that the ties to the cross bar should be located as far to the outside as possible, so forces aren't simply flexing the bar in the middle.

That bottom picture looks like it would help a little, but without triangulation, the engine is still just cantilevered out in the air. My guess is that it's not really worth the effort.

I agree that the ties to the cross bar should be located as far to the outside as possible, so forces aren't simply flexing the bar in the middle.

That bottom picture looks like it would help a little, but without triangulation, the engine is still just cantilevered out in the air. My guess is that it's not really worth the effort.

-

Ol'fogasaurus

- Posts: 17756

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Rear suspension, engine, and trans. bracing points

The picture I didn't post is the one that shows the bent area on the mount used for deflection on the "picklefork" (engine/transaxle mount) that allows the weight of the engine and transaxle to straighten out the mount.

On my first home made mount I located the welded in the 1 X 2 brace in front of the bend which did not help support the weight of the 091 and Cologne V-6 I was going to run. I personally like the diagonal braces to be as low as possible which is at the bolts into the picklefork.

Lee

On my first home made mount I located the welded in the 1 X 2 brace in front of the bend which did not help support the weight of the 091 and Cologne V-6 I was going to run. I personally like the diagonal braces to be as low as possible which is at the bolts into the picklefork.

Lee

- petew

- Posts: 3920

- Joined: Sat Oct 07, 2006 4:05 pm

Re: Rear suspension, engine, and trans. bracing points

There's a good reason why I've always called mendeola, "Spendeola". All those adjustable joints are overkill... and make some of that barwork useless.

BTW, from Jeff Hibbard's book, seam welding the "pickle fork" will probably help just as much as a kafer bar.

BTW, from Jeff Hibbard's book, seam welding the "pickle fork" will probably help just as much as a kafer bar.

-

Ol'fogasaurus

- Posts: 17756

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Rear suspension, engine, and trans. bracing points

Seam welding doesn't help stop the dance of death; the swinging, forking and jumping of the picklefork at different ladings. I'm not sure about what you are saying about the Mendel unit.

- ChadH

- Posts: 254

- Joined: Wed Mar 30, 2016 4:55 pm

Re: Rear suspension, engine, and trans. bracing points

Yes - that is on my list - I forgot. I did it on the front already. I probably should do the back before I dive into braces. I hate this kind of welding, because no matter how much prep I attempt, there's still stuff in the seams that spit, spatter, and make for ugly welds.petew wrote:..BTW, from Jeff Hibbard's book, seam welding the "pickle fork" will probably help just as much as a kafer bar.

- ChadH

- Posts: 254

- Joined: Wed Mar 30, 2016 4:55 pm

Re: Rear suspension, engine, and trans. bracing points

Looking closer at the Mendola, I don't like the big plate at the top of the shock mount, unless that whole plate is intended to be welded to the body or cage. It seems like the whole mess would twist or flex around the shock bolt area and negate any benefits. Tying it all up as close as possible to the top of the shock mount would be better IMHO.Ol'fogasaurus wrote:Seam welding doesn't help stop the dance of death; the swinging, forking and jumping of the picklefork at different ladings. I'm not sure about what you are saying about the Mendel unit.

- petew

- Posts: 3920

- Joined: Sat Oct 07, 2006 4:05 pm

Re: Rear suspension, engine, and trans. bracing points

The issue is the chassis ends ("pick fork" prongs) are seam welded every inch or so. Under load, the welded areas flex. The top and bottom halves move around on each other like you're burger slipping around as you eat. Welding the seams stops that movement. Sure, the whole length still flexes, but it's not trying to sheer the welds.Ol'fogasaurus wrote:Seam welding doesn't help stop the dance of death; the swinging, forking and jumping of the picklefork at different ladings. I'm not sure about what you are saying about the Mendel unit.

My point about seam welding helping as much is I'd do both; seam welding + kafer bars.