The ECU can take a couple revolutions to sync because when it starts, it has no idea what position the motor is in. You need up to 1 rev for it to identify TDC on the crank and up to 1 more rev to identify #1 cylinder from the cam.Camo wrote:Excellent stuff Chip. When you say the car fully synced up within a couple turns, do you need to position the cam sync in a particular spot like a distributor so the injector timing is spot on. I guess that the pickup inside needs to be timed or very close to the sweet spot so fuel is injected at the right time.

Sorry for my lack of knowledge, I'm new to EFI and just starting to fit my engine up with MS3x and will also be going full sequential fuel and ignition.

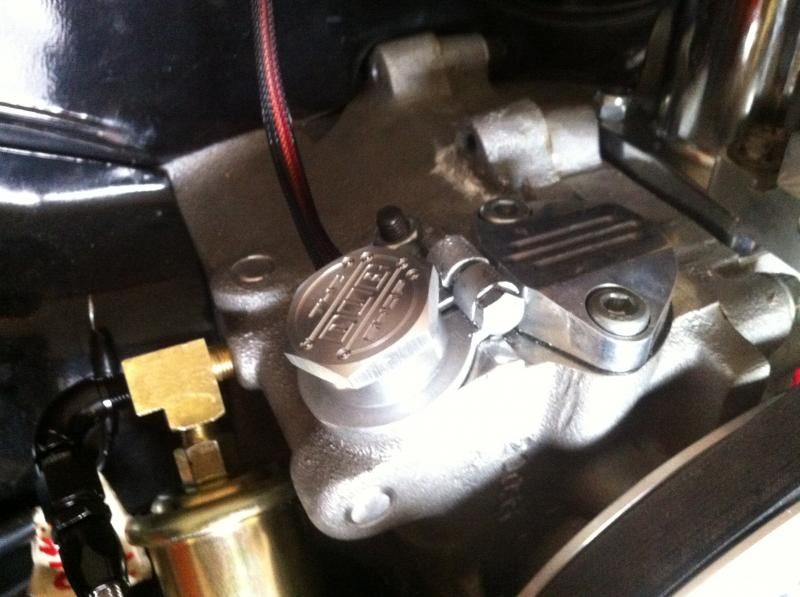

Good to see that Mario has started sending out the orders, I am looking forward to fitting my new engine up with one.

Cheers, Kev

In the typical MS missing tooth crank/single tooth cam setup, it doesn't matter much where the cam tooth is in relation to the missing tooth on the crank, but you cannot have them overlap. For example, you could run the cam tooth 30-40 degrees before the missing crank tooth, that is, if the missing tooth is 90 degrees BTDC, you position the cam tooth signal pulse at 120-130 degrees BTDC. If you happen to set the cam such that the engine Syncs and it still won't fire, it's probably out of phase and incorrectly thinking #3 is #1, so you just add 360 degrees to the Tooth #1 Angle and try again.