dry sump pumps

-

class5

- Posts: 12

- Joined: Wed Jan 12, 2005 11:02 pm

dry sump pumps

anyone know anything about the bug pack dry sump pumps .i know auto craft makes them just wondering about differnt mfg,s

-

MASSIVE TYPE IV

- Posts: 20132

- Joined: Fri Jul 07, 2000 12:01 am

The CB pump isn't a true dry sump arrangement.. It is used more like a wet sump that has an external oil reservoir since both stages share oil. I have ran these with good luck, but they can be difficult to fit to the TIV at times.

The Bugpack pump is a nice piece and I am assisting them with futrther development of it at the present time. It won't fit behind a stock TIV fan housing and thats the biggest killer for us.

The Bugpack pump is a nice piece and I am assisting them with futrther development of it at the present time. It won't fit behind a stock TIV fan housing and thats the biggest killer for us.

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Jake, now I am lost.

I ran a CB pump past summer and I am sure it was in my mind a real dry sump pump.

I evacuated the oil from the engine to my tank outside in the rear fender and then separately from the bottom of the tank I drew oil to a separate pressure stage through some filters prior to entering the engine.

Sure it is not as good as my Autocraft but it works on a circletrack very well. It keeps the engine free from exessive oil (to certain degree) and it gives me safe supply of oil in all directions of G forces.

Help me understand what you meant in difference between CB and Bugpack.

I ran a CB pump past summer and I am sure it was in my mind a real dry sump pump.

I evacuated the oil from the engine to my tank outside in the rear fender and then separately from the bottom of the tank I drew oil to a separate pressure stage through some filters prior to entering the engine.

Sure it is not as good as my Autocraft but it works on a circletrack very well. It keeps the engine free from exessive oil (to certain degree) and it gives me safe supply of oil in all directions of G forces.

Help me understand what you meant in difference between CB and Bugpack.

- Piledriver

- Moderator

- Posts: 22775

- Joined: Sat Feb 16, 2002 12:01 am

The CB 2 stage dry sump pumps stages do NOT actually "share" oil, except what leaks internally via the shaft .

As shipped, the oil is routed through 2 passages BETWEEN stages so it is usable as a ~drop-in arrangement in a T1 (or T4 with the usual shaft press/clearancing), but that is IMHO very ugly, with extra 90 degree bends and small passages.

(works as intended, but that's not remotely optimal)

It is easy to mod so that is NOT the case, and using a full flow cover, easy to "full flow"... esp so on a T4, as the "normal" output to the stock filter is available, you use it as the scavenge stage output easily. (I supported the inner plug to the main gallery to the outer with a setscrew in the outer, so it doesn't blow out internally)

It is also easy to plumb the modded CB pump as a "stage-and-a-half" ala 26MM pressure stage and 21mm scavenge stage (suck on 3/4 head or remote turbo for example)

For MOST people, the stage and a half wet-sump config makes more sense IMHO.

Mine is hacked up to fit a 914 with only one modified motor mount... I posted pics here somewhere of the modded pump details. For a "normal" upright conversion install, all the clearancing would not be required.

http://www.shoptalkforums.com/viewtopic.php?t=111275

It has a 21mm pressure stage and a 26mm scavenge stage.

(or 26mm pressure/21mm scavenge if set up as pump+1/2 wet sump)

It clears the stock fan housing with a full flow cover. (tiny amount of clearancing required on a stiffening rib of the FH, )

It will also clear the pulley on an upright conversion, at least the ones I have.

The electric "evac" pump mentioned draws 30A and didn't pull much vacuum... ~3-4in H2O, but makes one hell of a 12V hair dryer

As shipped, the oil is routed through 2 passages BETWEEN stages so it is usable as a ~drop-in arrangement in a T1 (or T4 with the usual shaft press/clearancing), but that is IMHO very ugly, with extra 90 degree bends and small passages.

(works as intended, but that's not remotely optimal)

It is easy to mod so that is NOT the case, and using a full flow cover, easy to "full flow"... esp so on a T4, as the "normal" output to the stock filter is available, you use it as the scavenge stage output easily. (I supported the inner plug to the main gallery to the outer with a setscrew in the outer, so it doesn't blow out internally)

It is also easy to plumb the modded CB pump as a "stage-and-a-half" ala 26MM pressure stage and 21mm scavenge stage (suck on 3/4 head or remote turbo for example)

For MOST people, the stage and a half wet-sump config makes more sense IMHO.

Mine is hacked up to fit a 914 with only one modified motor mount... I posted pics here somewhere of the modded pump details. For a "normal" upright conversion install, all the clearancing would not be required.

http://www.shoptalkforums.com/viewtopic.php?t=111275

It has a 21mm pressure stage and a 26mm scavenge stage.

(or 26mm pressure/21mm scavenge if set up as pump+1/2 wet sump)

It clears the stock fan housing with a full flow cover. (tiny amount of clearancing required on a stiffening rib of the FH, )

It will also clear the pulley on an upright conversion, at least the ones I have.

The electric "evac" pump mentioned draws 30A and didn't pull much vacuum... ~3-4in H2O, but makes one hell of a 12V hair dryer

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Hi Piledriver,

Thanks for the input and the link.

I had to search my own archives to see if I had any pictures but all I have is a lousy one.

In any case, I have done exactly as you mention in one alternative.

I plugged the pressure side and used an al cover.

I also remember putting few minutes in to radiusing the channels and hopefully improving the flow. In any case it looked better and I felt better.

The pump worked just fine and for the price, up to my expectation.

Putting the oil tank in the right side fender is another story (not so good outcome) and now the tank is up front.

Thanks for the input and the link.

I had to search my own archives to see if I had any pictures but all I have is a lousy one.

In any case, I have done exactly as you mention in one alternative.

I plugged the pressure side and used an al cover.

I also remember putting few minutes in to radiusing the channels and hopefully improving the flow. In any case it looked better and I felt better.

The pump worked just fine and for the price, up to my expectation.

Putting the oil tank in the right side fender is another story (not so good outcome) and now the tank is up front.

Last edited by Frallan on Fri Feb 29, 2008 7:01 pm, edited 1 time in total.

- TeamFRD

- Posts: 10

- Joined: Sat Sep 30, 2000 12:01 am

3 stage dry sump

This seems like the thread to keep alive...

I have a Formula Super Vee with a 3 stage oil pump - 3 gear sets. the set farthest from the case it the pressure side from the DS tank to filter to stock cooler location. The 2 sets on the case side (the scavange side) have a 3/16" plate between them with a hole in it to allow oil to flow into the middle gear set then out to the dry sump tank.

My question is: should this hole be on the same side as the pick up tube or on the exit side?

I have just disassembled it. The hole has been on the exit side. I am experiencing a full sump of oil after an autocross run. In other words, it is not pumping out as fast as it's pumping oil in. I'm checking for air leaks as well.

I have a Formula Super Vee with a 3 stage oil pump - 3 gear sets. the set farthest from the case it the pressure side from the DS tank to filter to stock cooler location. The 2 sets on the case side (the scavange side) have a 3/16" plate between them with a hole in it to allow oil to flow into the middle gear set then out to the dry sump tank.

My question is: should this hole be on the same side as the pick up tube or on the exit side?

I have just disassembled it. The hole has been on the exit side. I am experiencing a full sump of oil after an autocross run. In other words, it is not pumping out as fast as it's pumping oil in. I'm checking for air leaks as well.

- Piledriver

- Moderator

- Posts: 22775

- Joined: Sat Feb 16, 2002 12:01 am

Re: 3 stage dry sump

One regular (cant recall who ATM) had to rework his oil pickup setup due to similar symptomsTeamFRD wrote:This seems like the thread to keep alive...

I have a Formula Super Vee with a 3 stage oil pump - 3 gear sets. the set farthest from the case it the pressure side from the DS tank to filter to stock cooler location. The 2 sets on the case side (the scavange side) have a 3/16" plate between them with a hole in it to allow oil to flow into the middle gear set then out to the dry sump tank.

My question is: should this hole be on the same side as the pick up tube or on the exit side?

I have just disassembled it. The hole has been on the exit side. I am experiencing a full sump of oil after an autocross run. In other words, it is not pumping out as fast as it's pumping oil in. I'm checking for air leaks as well.

I have played with it, eliminating the swaged down spot for the fat oring, using a thin machined insert and 1/16" cross section orings. (I am STILL considering fabbing a complete new pickup)

This insert also eliminates (as pointed out by Tencentlife) the (probably) foamy oil return from the pressure relief that loops directly back to the pickup via an internal passage on later (hydro) cases.

Another head-slapping great Idea I borrowed from Racer Chris was to use an external oil pressure relief that dumps back to the TANK, rather than to the cases sump (eliminating the stock relief system).

The stock pressure relief setup could PROBABLY be modified to work, plugging the return in the block and having an output on the plug location at the base...

No use pumping it out twice, it didn't get used/hot or dirty.

The bigger the pump, the more those ideas will help.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Re: 3 stage dry sump

External pressure relief valve is and has been standard when you buy Autocraft pumps or Pauter.Piledriver wrote: Another head-slapping great Idea I borrowed from Racer Chris was to use an external oil pressure relief that dumps back to the TANK, rather than to the cases sump (eliminating the stock relief system).

The stock pressure relief setup could PROBABLY be modified to work, plugging the return in the block and having an output on the plug location at the base...

No use pumping it out twice, it didn't get used/hot or dirty.

.

Earlier designs of Autocraft, (at least the ones I have dealt with) had Ok but lesser good design by just bypassing it in to the scavenge side of the pump.

This is better and OK but not as good as a separate line to the tank.

The oil should always be returned to the tank. For me it is not an option but rather lazy design to do anything else.

Jaycees filter assembly with external perssure relief valve is nice, albeit slightly pricy.

- Wally

- Posts: 4564

- Joined: Mon Oct 28, 2002 12:01 am

There is only one dry-sump pump I use. Its the version they use in the german käferCup race series back in the days.

It has 26/38mm gears which are supported on both sides (the CB-schadeck is not).

It has 26/38mm gears which are supported on both sides (the CB-schadeck is not).

T4T: 2,4ltr Type 4 Turbo engine, 10.58 1/4 mi in a streetlegal 1303

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Hi Wally,

I also have some life partners.

It is my old Autocraft pump from 1989 and the System 1 filters bought far way back in 1987. Remember I bought 10 of them. Still have 4.

2 in parallel to lower the back pressure has been standard for me. I love them.

The other longtime partners for several of my TIV engines are the small double pickup sumps with coarse particle screens in the bottom.

The Autocraft pump has never missed a beat and is also supported with needle bearings up front.

Taking it apart for inspection is a joy. The parts are so nicely fit that it just feels right.

I also have some life partners.

It is my old Autocraft pump from 1989 and the System 1 filters bought far way back in 1987. Remember I bought 10 of them. Still have 4.

2 in parallel to lower the back pressure has been standard for me. I love them.

The other longtime partners for several of my TIV engines are the small double pickup sumps with coarse particle screens in the bottom.

The Autocraft pump has never missed a beat and is also supported with needle bearings up front.

Taking it apart for inspection is a joy. The parts are so nicely fit that it just feels right.

- Wally

- Posts: 4564

- Joined: Mon Oct 28, 2002 12:01 am

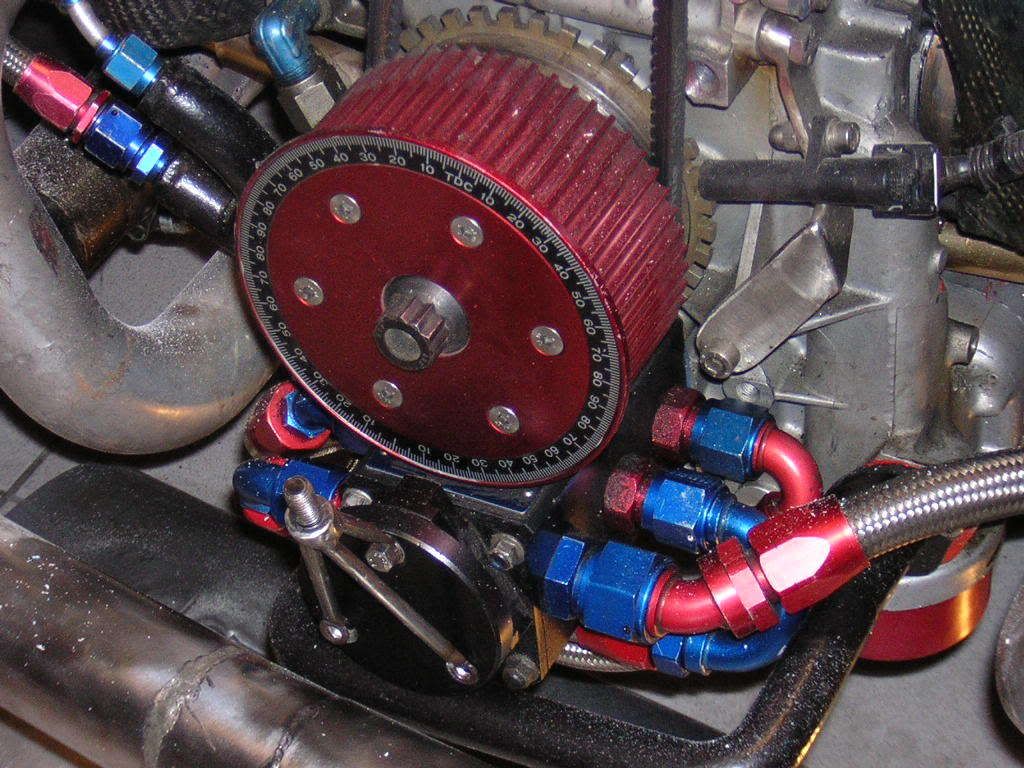

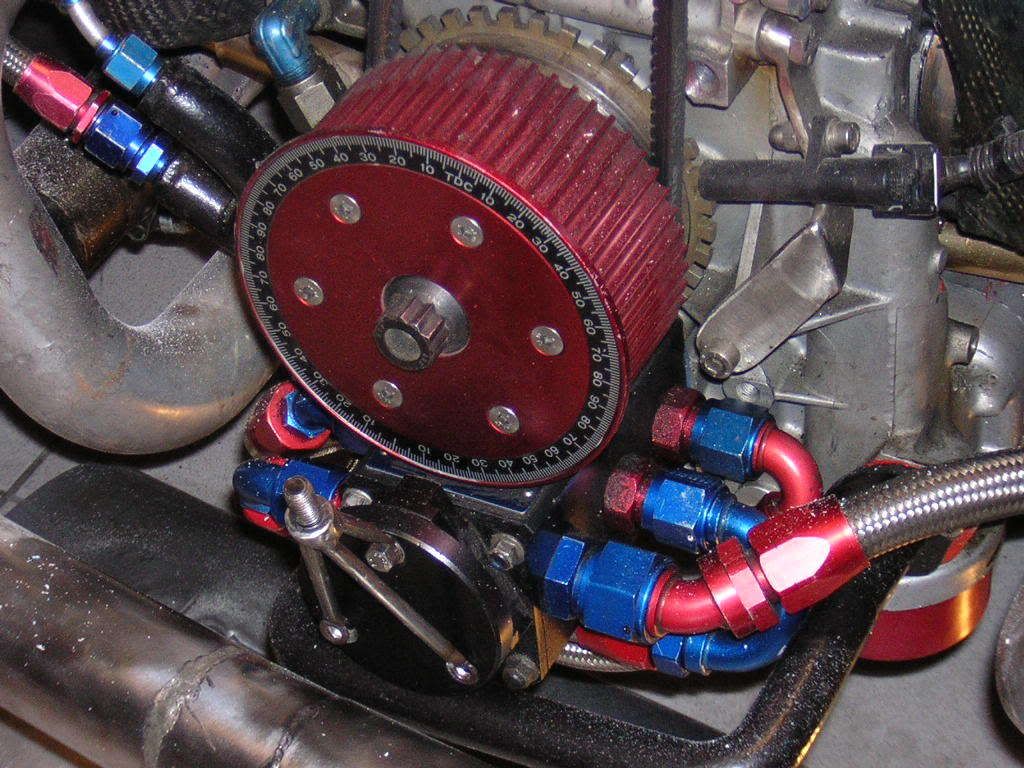

I like the double oil filter idea Frallan! My DS pump does not have needle bearings, but si-bronze which is more than enough for oil pumps as it turns out to me. Still, you can never have too much quality right?

but a pump that long and all those lines together on your old supercharger engine look way to complicated (for a street engine) to me to be honest

but a pump that long and all those lines together on your old supercharger engine look way to complicated (for a street engine) to me to be honest

T4T: 2,4ltr Type 4 Turbo engine, 10.58 1/4 mi in a streetlegal 1303

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

- TeamFRD

- Posts: 10

- Joined: Sat Sep 30, 2000 12:01 am

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Hi David,

I do not have a good picture of an external pressure relief valve right now.

I will try tonight.

Not sure about your question on having the hole on the right side.

If you could show us a picture it might help.

As for returning the oil from the external pressure relief, it is under pressure so it will go back to the tank at any level.

I suggest you should try to have the drysump tank as low as possible and best is fairly level with the engine.

An oil pump does leak when it is not running and if standing still for a long time, often the level between tank and engine will even out.

You could cause damages in your enegine if you start it with 12 liters of oil instead of 3-4.

The bottom sumps look like this.

I noramlly have a slighter finer screen below the rough one in this picture.

The inlets are hand radiused but I have no detailed picture of that right now.

I do not have a good picture of an external pressure relief valve right now.

I will try tonight.

Not sure about your question on having the hole on the right side.

If you could show us a picture it might help.

As for returning the oil from the external pressure relief, it is under pressure so it will go back to the tank at any level.

I suggest you should try to have the drysump tank as low as possible and best is fairly level with the engine.

An oil pump does leak when it is not running and if standing still for a long time, often the level between tank and engine will even out.

You could cause damages in your enegine if you start it with 12 liters of oil instead of 3-4.

The bottom sumps look like this.

I noramlly have a slighter finer screen below the rough one in this picture.

The inlets are hand radiused but I have no detailed picture of that right now.

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am