Jeff

CENTERMOUNT FAN SHROUD DUCTING INSERT

- JiI

- Posts: 82

- Joined: Sat Sep 10, 2005 12:19 pm

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Well, if it all works out...GIMMIE!!!!!!!

Jeff

Jeff

- GoMopar440

- Posts: 258

- Joined: Sun Apr 12, 2015 8:56 am

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Sign me up!FJCamper wrote:Hi Jeff,

Yes, we will sell them if the design proves reliable.

FJC

It looks like a MUCH neater solution VS the hack job I did to my DH fan housing. Are you going to sell them as kits with the insert, fan housing and a center mount for the alt? Or just the insert?

Home made rail (street legal), 1600 DP, 34PICT-3, T3 brakes, 4-1 glass-pack exhaust, 31's in back and 7.00x15's up front. Link to build thread: viewtopic.php?f=28&t=147561&p=1227553#p1227553

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Ho GoMopar,

We are thinking just the insert. But maybe we can offer a preassembled housing if anyone wants it.

FJC

We are thinking just the insert. But maybe we can offer a preassembled housing if anyone wants it.

FJC

- GoMopar440

- Posts: 258

- Joined: Sun Apr 12, 2015 8:56 am

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Pre-assembly isn't too important to me, I really like building stuff myself.

I may be an old gear head, but I'm fairly new to VW's, so I don't have a bunch of spare VW parts to pick from yet. I'd have to gather all the separate pieces and parts that go with the insert first in order to make it work. I'm not sure where to find the center mount for the alternator in particular. The center mount shroud looks like it would be fairly easy to find in comparison to the alt stand. I'd also need a fuel pump block off and an electric fuel pump, but those are relatively easy to find.

I had a few more questions related to the insert setup.

- Are there any other pieces required to make it work that I haven't mentioned yet?

- Does the alternator take a different length fan belt with the center mount alt stand?

- Does the center mounted alternator interfere with fitting a standard 4 into 1 Baja type header?

I'm not in a big rush to answer these questions yet since I'm still in the middle of rebuilding my rail and making it street legal right now. I can wait for the answers until you've tested it out and then decided if you want to sell them or not.

I may be an old gear head, but I'm fairly new to VW's, so I don't have a bunch of spare VW parts to pick from yet. I'd have to gather all the separate pieces and parts that go with the insert first in order to make it work. I'm not sure where to find the center mount for the alternator in particular. The center mount shroud looks like it would be fairly easy to find in comparison to the alt stand. I'd also need a fuel pump block off and an electric fuel pump, but those are relatively easy to find.

I had a few more questions related to the insert setup.

- Are there any other pieces required to make it work that I haven't mentioned yet?

- Does the alternator take a different length fan belt with the center mount alt stand?

- Does the center mounted alternator interfere with fitting a standard 4 into 1 Baja type header?

I'm not in a big rush to answer these questions yet since I'm still in the middle of rebuilding my rail and making it street legal right now. I can wait for the answers until you've tested it out and then decided if you want to sell them or not.

Home made rail (street legal), 1600 DP, 34PICT-3, T3 brakes, 4-1 glass-pack exhaust, 31's in back and 7.00x15's up front. Link to build thread: viewtopic.php?f=28&t=147561&p=1227553#p1227553

- JiI

- Posts: 82

- Joined: Sat Sep 10, 2005 12:19 pm

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

I would love if you offered a fan shroud (and the alt. stand!) But even if you offered it as a kit or the CAD specs, I'm sure I could build one.FJCamper wrote:Ho GoMopar,

We are thinking just the insert. But maybe we can offer a preassembled housing if anyone wants it.

FJC

Jeff

- Piledriver

- Moderator

- Posts: 22776

- Joined: Sat Feb 16, 2002 12:01 am

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Edit: For some reason I thought SACO made the setup, probably thinking the `glass centermount setups they do in glass.

(The custom insert would be an almost pointless project without it)

(The custom insert would be an almost pointless project without it)

Last edited by Piledriver on Fri May 13, 2016 6:16 am, edited 1 time in total.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

- GoMopar440

- Posts: 258

- Joined: Sun Apr 12, 2015 8:56 am

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Pile: I definitely agree with your comment on the usefulness of a product (the insert) designed to work with separately produced parts. One is no good without the other. Hence my earlier questions about a complete kit with the shroud and center alt mount. As long as those related parts can still be found and bought, it's a non-issue.

BTW, it's nice to see a SF reference being used in everyday language every now and then.

Marc: Thanks for that link. $150 doesn't seem too bad for a shroud and alt stand to me. That's probably partially because I don't know what that kind of stuff used to cost, even just a couple of years ago. I only just got my rail (first VW for me) about a year ago.

Now we'll just have to wait for the results of FJ's testing to see if this insert will work well enough to put into production, which I really hope it does. I like to support grass roots technology stuff like this, especially when it helps support a fellow forum member's racing efforts.

BTW, it's nice to see a SF reference being used in everyday language every now and then.

Marc: Thanks for that link. $150 doesn't seem too bad for a shroud and alt stand to me. That's probably partially because I don't know what that kind of stuff used to cost, even just a couple of years ago. I only just got my rail (first VW for me) about a year ago.

Now we'll just have to wait for the results of FJ's testing to see if this insert will work well enough to put into production, which I really hope it does. I like to support grass roots technology stuff like this, especially when it helps support a fellow forum member's racing efforts.

Home made rail (street legal), 1600 DP, 34PICT-3, T3 brakes, 4-1 glass-pack exhaust, 31's in back and 7.00x15's up front. Link to build thread: viewtopic.php?f=28&t=147561&p=1227553#p1227553

-

petfisheric

- Posts: 1

- Joined: Mon May 25, 2015 5:13 am

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Well how did it go? I've been silently following your thread and waiting for the thumbs up. I'm hopping you will post good news so I can up grade my Puma GTC from the standard type I fan shroud.

- JiI

- Posts: 82

- Joined: Sat Sep 10, 2005 12:19 pm

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

So how did the testing go?

Jeff

Jeff

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

IT WORKS

First the good news. It works. Now the bad news. We only got to bench test our 1600, not track test.

However, just from the bench engine stand testing we can see the insert is already exceeding expectations, and we learned how to improve our test parameters.

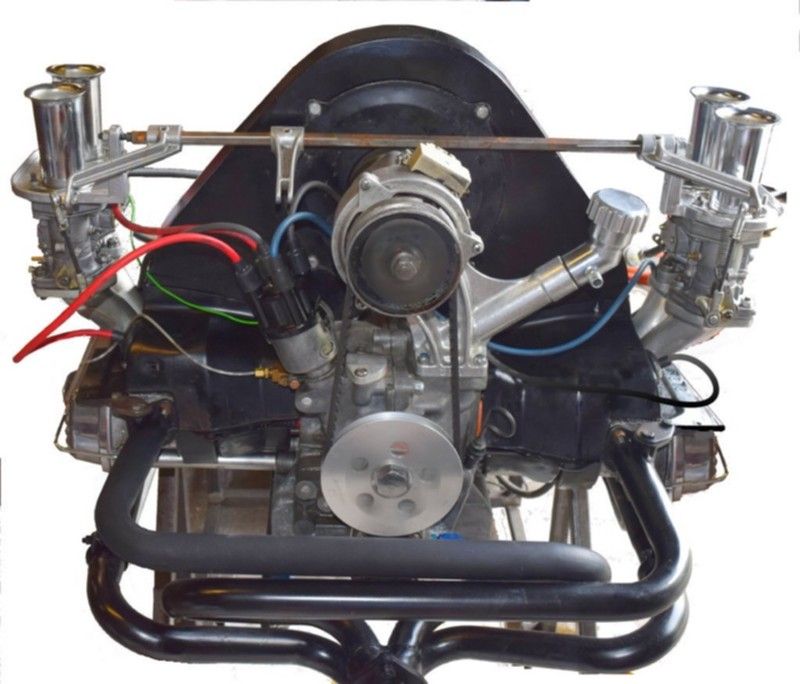

The photo above shows the fan housing's special alternator stand will work with a CB Performance dry sump pulley and pump. The test engine was dry sump.

No vibration, noise, or other similar problems occurred throughout the RPM ranges. The insert and fan housing acted as one piece.

We can see that inserting an accelerator cable tube is a bit tricky, as it must exit about midway up the alternator's centerline and just outside of the mounting plate. Also, Kads are almost out of the question because of the need for a low profile linkage mechanism. The special alt stand takes up that space.

In fact, we couldn't track test with the Historic Motor Sports Association at Barber, because we had to be very, very, period correct, and we could do it with Kads (as Solexes) but not Webers. HMSA is very serious about period correct cars, and will not even allow modern dot-com decals or ads on the cars.

A test problem we encountered was we used Type 3 "cool tin" on the engine, and should have used the regular deflectors. The cool tin hampered our ability to simply feel (by hand) under the running engine to gauge airflow.

More later--

FJC

- JiI

- Posts: 82

- Joined: Sat Sep 10, 2005 12:19 pm

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Okay, now I'm drooling!

Jeff

Jeff

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Who offers that "bent" oil filler extension? I've only seen the straight ones, it looks like yours would be easier to add oil without spillage.

Gene Berg linkage can be adapted to just about any carbs on the planet. It's intended to be mounted to the shroud using three stock m6 bolt locations; with the centermount only two remain and they're relocated so you'd need to work that out but it shouldn't be difficult. Obviously it's vitally important that the shroud be solidly mounted, so additional bracing off of the case and/or alternator may be needed to keep the linkage from shifting.

Since (like the crossbar style) it pushes down on the throttle levers rather than pushing or pulling them horizontally, it's unaffected by engine-width growth.

An issue I've encountered with the crossbar linkage is that since the cable lever isn't centered on the bar there's more twist on the RH side, and any play in the pivot points also reduces travel at the RH carb - typically you need a slightly shorter lever on the RH carb than on the LH to compensate. The Berg linkage almost totally avoids these effects, and usually all that's needed is to bend the LH upper linkage arm to the side a little to shorten its effective length.

With very few exceptions, all you need to do when switching to different carbs is change the down-rods. Berg offers several varieties but they're easy to make from ¼" bar stock using an NF die. Both ends are RH thread so fine adjustments by simply twirling the rods isn't feasible, you need to unbolt one end and adjust the length in full-turn increments, but once initial setup is done they rarely need tweaking.

It costs about $200 new but it could be the last linkage you ever buy. Would not be too hard to make one yourself that incorporates the same principles - it looks like they used a bedframe rail to prototype the design

Another thought - could be used on either the crossbar or Berg-style linkage - would be to use a longer throttle cable routed through a Bowden tube to bring it over the shroud and back around to a bracket off the alternator housing so it could pull on an upward-pointed lever moved to dead center. On my mid-engine car I did something similar (of course it needed a shorter cable and it didn't need to turn 180°) which worked well.

Gene Berg linkage can be adapted to just about any carbs on the planet. It's intended to be mounted to the shroud using three stock m6 bolt locations; with the centermount only two remain and they're relocated so you'd need to work that out but it shouldn't be difficult. Obviously it's vitally important that the shroud be solidly mounted, so additional bracing off of the case and/or alternator may be needed to keep the linkage from shifting.

Since (like the crossbar style) it pushes down on the throttle levers rather than pushing or pulling them horizontally, it's unaffected by engine-width growth.

An issue I've encountered with the crossbar linkage is that since the cable lever isn't centered on the bar there's more twist on the RH side, and any play in the pivot points also reduces travel at the RH carb - typically you need a slightly shorter lever on the RH carb than on the LH to compensate. The Berg linkage almost totally avoids these effects, and usually all that's needed is to bend the LH upper linkage arm to the side a little to shorten its effective length.

With very few exceptions, all you need to do when switching to different carbs is change the down-rods. Berg offers several varieties but they're easy to make from ¼" bar stock using an NF die. Both ends are RH thread so fine adjustments by simply twirling the rods isn't feasible, you need to unbolt one end and adjust the length in full-turn increments, but once initial setup is done they rarely need tweaking.

It costs about $200 new but it could be the last linkage you ever buy. Would not be too hard to make one yourself that incorporates the same principles - it looks like they used a bedframe rail to prototype the design

Another thought - could be used on either the crossbar or Berg-style linkage - would be to use a longer throttle cable routed through a Bowden tube to bring it over the shroud and back around to a bracket off the alternator housing so it could pull on an upward-pointed lever moved to dead center. On my mid-engine car I did something similar (of course it needed a shorter cable and it didn't need to turn 180°) which worked well.

- Piledriver

- Moderator

- Posts: 22776

- Joined: Sat Feb 16, 2002 12:01 am

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

I don't quite get the "period correct" part banning Webers---

They have been used since the 60s on ACVWs and Porsches.

(Might technically need to be IDAs, not sure when they started making IDFs, but still...)

A pair of Solex duals would certainly be period correct.

I wonder if Slowtwitch makes a SyncLink for Kads.

A DIY version is certainly an option as well.

As to cost: If it works as intended, and the insert doesn't cost a fortune to make, it would cost about 1/4th the equivalent from Aircooled Technology, assuming the T1 DTM is still made.

I also see it as a potential win on T4 Cali style cooling setups, the only thing missing would be sanely priced glass cylinder tins for T4.

They have been used since the 60s on ACVWs and Porsches.

(Might technically need to be IDAs, not sure when they started making IDFs, but still...)

A pair of Solex duals would certainly be period correct.

I wonder if Slowtwitch makes a SyncLink for Kads.

A DIY version is certainly an option as well.

As to cost: If it works as intended, and the insert doesn't cost a fortune to make, it would cost about 1/4th the equivalent from Aircooled Technology, assuming the T1 DTM is still made.

I also see it as a potential win on T4 Cali style cooling setups, the only thing missing would be sanely priced glass cylinder tins for T4.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Re: CENTERMOUNT FAN SHROUD DUCTING INSERT

Hi Piledriver,

Your logic and facts will not overcome the wealthy gentlemen racers with their Ferrari 250's and original Ford GT40's. The group we just ran with, Historic Motor Sports Association out of California, has no official rule book.

www.hmsausa.com

Their site tells you they have the wealthiest membership of all vintage groups, and roll bars are recommended, but not required, no matter what class or period. And no unsightly trailers in the paddock! And no modern ads or decals on the car out of its era.

Any racing body that asks on the driver info sheet "what have you contributed to art and science" has to be eccentric and entertaining.

My prep for our Ghia was to strip off what few modern decals we had, and bolt on the Kads hoping to defend them as twin VW Solex carbs in some sort of obscure European option, in case tech was going to exert the opinion that the Ghia had to run with original equipment -- meaning a single carb -- as if it were an SCCA showroom stocker in that we have a good stout bolt-in 6-point roll bar.

I hope this doesn't sound like I'm complaining. I'm not. Each historic group is different.

FJC

Your logic and facts will not overcome the wealthy gentlemen racers with their Ferrari 250's and original Ford GT40's. The group we just ran with, Historic Motor Sports Association out of California, has no official rule book.

www.hmsausa.com

Their site tells you they have the wealthiest membership of all vintage groups, and roll bars are recommended, but not required, no matter what class or period. And no unsightly trailers in the paddock! And no modern ads or decals on the car out of its era.

Any racing body that asks on the driver info sheet "what have you contributed to art and science" has to be eccentric and entertaining.

My prep for our Ghia was to strip off what few modern decals we had, and bolt on the Kads hoping to defend them as twin VW Solex carbs in some sort of obscure European option, in case tech was going to exert the opinion that the Ghia had to run with original equipment -- meaning a single carb -- as if it were an SCCA showroom stocker in that we have a good stout bolt-in 6-point roll bar.

I hope this doesn't sound like I'm complaining. I'm not. Each historic group is different.

FJC