FJC, I just checked out your homepage, a great site BTW.

Isn't the Ghia you guys run with IRS as in the drawing above? IRS rear suspension has a geometric roll center which is pretty much at the same height as the front suspension, which is at ground level.

Your drawing looks like it's for a swing axle, but it should take into account that the "n-line" goes from the contact patch to the instant center that is at the hinge point in the gear box, so the roll center for a swing axle rear suspension is always above the center of the differential.

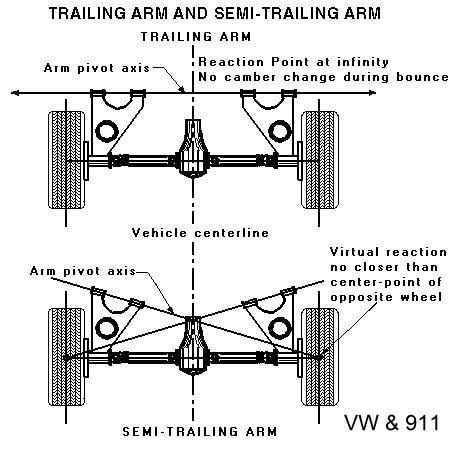

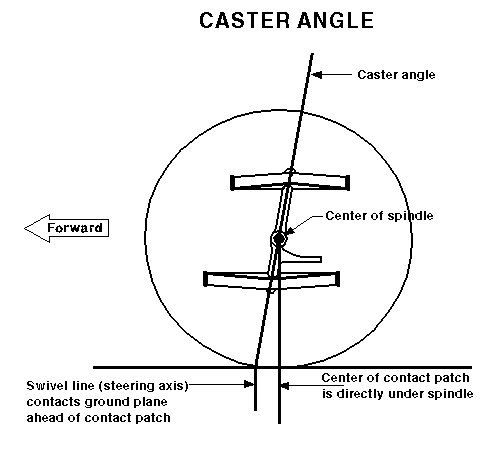

I noticed from the first picture that the trailing arms on that Auto Union is horizontal. Isn't the front trailing arms on a beetle suspension in an angle with the front end higher than the rear? Having them horizontal should reduce the wheelbase change in bump and reduce the pro-dive geometry of a stock bug suspension so the suspension might work better. Caster and bump steer should be taken into account if you decide to go this route.

GP-Winning Racing Front Suspension

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Rolling on...

Hi KDF,

Yes, the IRS rear roll center is lower than the swing axle, but not by much. The swing axle is actually at a point just above the input shaft, and the IRS just below the input shaft.

The determining line is the pivot of the semi-trailing arm where it joins the chassis. And not a bad roll center, either.

My drawing was a general reference to the roll center as being in the "middle" of the swing axle.

The Auto Union actually does use the same technique as the VW axle, in that the lower tube is slightly ahead of the semi-tube top dampner mounts. It's just hard to see in that photo.

One of the big caster differences in the old cars in general and the Auto Unions in specific is they didn't use as much caster as we do today, to reduce steering effort.

Thanks for the comments on our site. It's been neglected for a year as Barret has been in Afghanistan.

FJC

-

kdf

- Posts: 110

- Joined: Fri Jun 03, 2005 5:37 am

Re: Rolling on...

I hope I'm not bringing more confusion into this subject. Roll centers used to drive me crazy a while back (and I'm probably not the only one who has felt this way).

Your picture describes the difference of trailing arm and semi-trailing arm rear suspension. The change in the angle of the lines through the pivot points shows what causes the camber and toe change that the designers wanted to achieve in a semi-trailing rear suspension.

Above is a picture of geometric roll centers in a IRS rear suspension Ghia.

Above is a picture of geometric roll centers in a Swing rear suspension Ghia.

I don't think of roll centers as roll centers. I think of this phenomenon as how external forces affect the car through the suspension links. Roll centers are a bit difficult when you have to translate a approximate point that moves around and really doesn't do anything. What I use could probably be described as calculating jacking forces for each wheel. If the jacking force on a outside wheel is x and the jacking force on the inside wheel is y you get the geometric roll resistance by adding them together.

Geometric roll centers can cause a anti or pro geometry, this geometry either resists roll or causes more roll. If the roll center is at ground level, lateral forces don't create any roll resistance through the suspension geometry.

The geometric roll center (as discussed in this thread) is not the point that the car rolls around, I guess the name comes from when air plane axis systems were translated for automotive use. In real world the friction in the bushings of the suspension, the flex in the suspension arms and mounting points and the tires affect the roll center. Every one of these real world parts that you add to the calculations will raise the roll center, so in the real world, even the front axle of a bug has a roll center higher than ground level.

The axis of roll of a car is very difficult to measure, and for this you will need a system that measures where the body of the car is. This is probably done on 7-post rigs because it's quite difficult to measure when live testing a car. You could get an approximate value by using suspension position sensors and laser ride height sensors and you'd need a correction for banking angle in each corner. In addition to all these sensors it would require very complicated mathematics to get the properties for the tires and suspension so that the numbers from these calculations are somewhere near the real world values..

I just got the opportunity to use a high level simulation software for cars, and I'm just learning the basics to use it. It has no input for roll centers and I suspect that no professional car suspension designers use the roll center value.

I think you might mix up instantaneous center of rotation (IC) or Reaction point as called in your picture, with roll center. The IC is the single "hinge" point that the contact patch and tire rotates around when there is suspension. You are right that the IC can be at the same height in a Swing or IRS suspension, but the geometric roll center is at a very different place.FJCamper wrote:Yes, the IRS rear roll center is lower than the swing axle, but not by much. The swing axle is actually at a point just above the input shaft, and the IRS just below the input shaft.

The determining line is the pivot of the semi-trailing arm where it joins the chassis. And not a bad roll center, either.

My drawing was a general reference to the roll center as being in the "middle" of the swing axle.

Your picture describes the difference of trailing arm and semi-trailing arm rear suspension. The change in the angle of the lines through the pivot points shows what causes the camber and toe change that the designers wanted to achieve in a semi-trailing rear suspension.

Above is a picture of geometric roll centers in a IRS rear suspension Ghia.

Above is a picture of geometric roll centers in a Swing rear suspension Ghia.

I don't think of roll centers as roll centers. I think of this phenomenon as how external forces affect the car through the suspension links. Roll centers are a bit difficult when you have to translate a approximate point that moves around and really doesn't do anything. What I use could probably be described as calculating jacking forces for each wheel. If the jacking force on a outside wheel is x and the jacking force on the inside wheel is y you get the geometric roll resistance by adding them together.

Geometric roll centers can cause a anti or pro geometry, this geometry either resists roll or causes more roll. If the roll center is at ground level, lateral forces don't create any roll resistance through the suspension geometry.

The geometric roll center (as discussed in this thread) is not the point that the car rolls around, I guess the name comes from when air plane axis systems were translated for automotive use. In real world the friction in the bushings of the suspension, the flex in the suspension arms and mounting points and the tires affect the roll center. Every one of these real world parts that you add to the calculations will raise the roll center, so in the real world, even the front axle of a bug has a roll center higher than ground level.

The axis of roll of a car is very difficult to measure, and for this you will need a system that measures where the body of the car is. This is probably done on 7-post rigs because it's quite difficult to measure when live testing a car. You could get an approximate value by using suspension position sensors and laser ride height sensors and you'd need a correction for banking angle in each corner. In addition to all these sensors it would require very complicated mathematics to get the properties for the tires and suspension so that the numbers from these calculations are somewhere near the real world values..

I just got the opportunity to use a high level simulation software for cars, and I'm just learning the basics to use it. It has no input for roll centers and I suspect that no professional car suspension designers use the roll center value.

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Advanced subject

Hi KDF,

All of the esoterics of roll center science/theory are interesting to guys like you and me, but not the average car guy.

My point about the more simplistic elements of the front and rear roll centers on the Auto Union, VW, and VW designs is to those who are altering these without knowing what to expect.

This is what I'd like them to take away from this cautionary tale:

A high roll center allows more body roll than a low roll center. A swing axle has a high roll center, and Porsche countered that with a low front roll center to make the front end do most of the cornering work.

Dr. Porsche's use of the beam axle trailing arm front suspension allowed the axle itself to lean with the body and automatically create front end breakaway as the front tires leaned.

Understeer was a by-product of the very simple VW front suspension trailing arm design.

In short, the design of the front suspension was made to work with the quirks of the rear.

Of all the design-theory books out there, I'd recommend Fred Puhn's How To Make your Car Handle by HP Books to those who want a good general understanding of this very complex subject.

FJC

All of the esoterics of roll center science/theory are interesting to guys like you and me, but not the average car guy.

My point about the more simplistic elements of the front and rear roll centers on the Auto Union, VW, and VW designs is to those who are altering these without knowing what to expect.

This is what I'd like them to take away from this cautionary tale:

A high roll center allows more body roll than a low roll center. A swing axle has a high roll center, and Porsche countered that with a low front roll center to make the front end do most of the cornering work.

Dr. Porsche's use of the beam axle trailing arm front suspension allowed the axle itself to lean with the body and automatically create front end breakaway as the front tires leaned.

Understeer was a by-product of the very simple VW front suspension trailing arm design.

In short, the design of the front suspension was made to work with the quirks of the rear.

Of all the design-theory books out there, I'd recommend Fred Puhn's How To Make your Car Handle by HP Books to those who want a good general understanding of this very complex subject.

FJC