How to Stop Fuel fitting from Falling out of Solex carbs

- david58

- Moderator

- Posts: 14101

- Joined: Sun Oct 23, 2005 6:14 pm

How to Stop Fuel fitting from Falling out of Solex carbs

Let's see your fixes.

Last edited by david58 on Sat Aug 29, 2009 3:09 am, edited 1 time in total.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- david58

- Moderator

- Posts: 14101

- Joined: Sun Oct 23, 2005 6:14 pm

- david58

- Moderator

- Posts: 14101

- Joined: Sun Oct 23, 2005 6:14 pm

Is any drilling required before tapping them?jrandy wrote:I take the tops off and tap them for 1/4in pipe fittings.

Actually, some of the later carbs I have tried to remove the stock fittings and they would not come out.

Did somebody address this problem at some point?

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

-

jrandy

- Posts: 498

- Joined: Wed Oct 03, 2007 10:39 pm

Yes, it was necessary to drill the top out to fit the tap for the pipe fitting.

I figure once the fit between the tube and the top is eroded to the point of falling apart I am willing to take the chance with drilling the top.

I put the top in a vice with some softer material on the vice jaws to keep from galling the mating surface for the top.

The aluminum is very soft and the drill will bite right into it if you are not careful and/or use some sort of stop for the drill bit.

The boss for the brass fitting is pretty thin, but there is enough material there to do the deal if you are careful.

I figure once the fit between the tube and the top is eroded to the point of falling apart I am willing to take the chance with drilling the top.

I put the top in a vice with some softer material on the vice jaws to keep from galling the mating surface for the top.

The aluminum is very soft and the drill will bite right into it if you are not careful and/or use some sort of stop for the drill bit.

The boss for the brass fitting is pretty thin, but there is enough material there to do the deal if you are careful.

- fusername

- Posts: 6806

- Joined: Sun Jan 28, 2007 11:26 am

I am actually going to attempt this this weekend, if my bus doesn't run me over first. The nice thing about NPT taps, is that they have the proper drill size stamped right on em.

give a man a watch and he'll allways know what time it is. give him two and he can never be sure again.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

- david58

- Moderator

- Posts: 14101

- Joined: Sun Oct 23, 2005 6:14 pm

-

aussiebug

- Posts: 1520

- Joined: Wed Mar 07, 2001 12:01 am

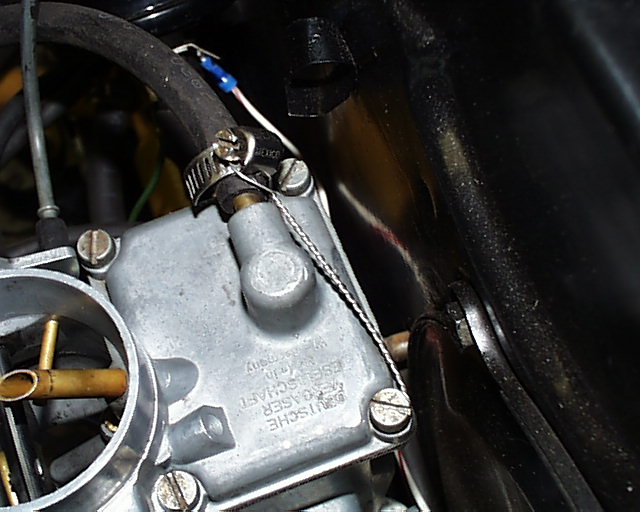

I knurl them as shown in the pic above, but I prefer to use the edge of a flat file with single cut teeth, and run the file at 90 degrees to the pipe so you get just about 1/4 inch of knurled surface, a little behind the end of the pipe which will be in the hole. This methods produces a set of single ridges running parallel around the pipe (like gear teeth), so the inside of the carby top does not get chewed out by multiple "teeth" when the pipe it tapped back in to the hole.

The "bottom" end of the pipe must remain smooth as this is what seals the pipe in the hole and stops fuel leaking out.

I've never had one fall out or leak after using this simple process.

Oh - and never put a fuel filter in the line between pump and carby - this increases the likelihood of that brass pipe falling out - extra weight vibrating the fuel line and carby inlet pipe. The fuel filter should be before the fuel pump so both the pump and carby get nice clean fuel.

The "bottom" end of the pipe must remain smooth as this is what seals the pipe in the hole and stops fuel leaking out.

I've never had one fall out or leak after using this simple process.

Oh - and never put a fuel filter in the line between pump and carby - this increases the likelihood of that brass pipe falling out - extra weight vibrating the fuel line and carby inlet pipe. The fuel filter should be before the fuel pump so both the pump and carby get nice clean fuel.

Regards

Rob

Rob and Dave's aircooled VW pages

Repairs and Maintenance for the home mechanic

www.vw-resource.com

Rob

Rob and Dave's aircooled VW pages

Repairs and Maintenance for the home mechanic

www.vw-resource.com

- Bookwus

- Posts: 281

- Joined: Thu Feb 15, 2001 12:01 am

And to add just a bit to what Rob had to say.............

I also follow the same routine advocated by Rob. Additionally I also coat the knurled end with just a bit of JB Quickweld when I tap it into place. On top of that I use the wire restraint also.

This may seem like a bit of overkill but, then again, I've seen a couple of engine fires up close. I'll go with the overkill any day.

I also follow the same routine advocated by Rob. Additionally I also coat the knurled end with just a bit of JB Quickweld when I tap it into place. On top of that I use the wire restraint also.

This may seem like a bit of overkill but, then again, I've seen a couple of engine fires up close. I'll go with the overkill any day.

-

volkenstein

- Posts: 114

- Joined: Sun Nov 20, 2005 9:53 pm

- david58

- Moderator

- Posts: 14101

- Joined: Sun Oct 23, 2005 6:14 pm

I agree with Piledriver you still need hose clamps.sideshow wrote:My method, just make a pseudo strain relief to keep both the carb and fuel pump barbs from being able to escape.

You stated in another thread that for your era car they didn't come with hose clamps from the factory. Ever wonder why a car burned? Clamps might have saved a slew of VW's.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- sideshow

- Posts: 3428

- Joined: Mon Oct 27, 2003 11:00 am

The problem I'm addressing keeping the barbs from falling out. A separate issue could be made that the stock cloth braided fuel line does not benefit from have some worm drive clamp crushing them.

And no I don't wonder why a car burns, I'm certain that clamps do not fix stupid, but if I had to bet;

And no I don't wonder why a car burns, I'm certain that clamps do not fix stupid, but if I had to bet;

- A pressed in barb, that is allowed to fall out

Some expert using ¼ inch SAE line over a much smaller barb and claims a clamp “will hold that”

Electric fuel pumps that continue to run (no factory like shut off) when engine stalls

Pure neglect, as in no line should be moist, external filters should not crack, run away vibration, or something caught in say a fan belt

Yeah some may call it overkill, but you can't have too much overkill.

- Piledriver

- Moderator

- Posts: 22776

- Joined: Sat Feb 16, 2002 12:01 am

A GOOD clamp like one of the spring loaded ones (very annoying but work great, whatever they are called) or a proper EFI clamp will not eat the hose.

I understand what you are saying, but still disagree somewhat.

The optimal combination would be a screw in fitting and properly strain relieved line.

Also, Use SAER9/11 hose (AKA EFI hose) rather than the R7 "not for fuel injection" hose... Yes, it costs ~ double, but it won't dry rot in 6 months. Should last many years with proper clamps.

I understand what you are saying, but still disagree somewhat.

The optimal combination would be a screw in fitting and properly strain relieved line.

Also, Use SAER9/11 hose (AKA EFI hose) rather than the R7 "not for fuel injection" hose... Yes, it costs ~ double, but it won't dry rot in 6 months. Should last many years with proper clamps.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

aussiebug

- Posts: 1520

- Joined: Wed Mar 07, 2001 12:01 am

David 58 and Piledriver say you MUST use clamps.

But in fact the cotton covered 5.5mm VW fuel hose does not need clamps - the cotton covering does that for you.

Just try pulling a fuel line off without twisting as you do. The braided cotton covering works like a Chinese finger trap and tightens when it's pulled.

There is nothing wrong with using clamps too, but they are not really necessary if you use the correct fuel line.

VW made 22 million bugs which did not use clamps on the hoses, and they were/are GOOD engineers.

The lack of clamps does not cause fuel fires - engine fires are almost invariably a result of the brass inlet spigot falling out of the top of the carby with the fuel line still attached, and as described above there are various good methods of preventing this happening. The other main cause is the fuel line itself not being replaced after a reasonable time so it cracks under the cotton coveriing, or starts to split at the ends, and sprays fuel.

One problem which does exists now which did not exist a few years ago is the quality of the "genuine" VW fuel hose. It's often very thin walled and rots/cracks in a few months. My local VW supplier now gets fuel hose for early BMWs which is exactly the same as the 5.5mm VW hose of old, and this stuff is much thicker walled, better quality rubber, and lasts like the original VW fuel hose did - several years at least.

But in fact the cotton covered 5.5mm VW fuel hose does not need clamps - the cotton covering does that for you.

Just try pulling a fuel line off without twisting as you do. The braided cotton covering works like a Chinese finger trap and tightens when it's pulled.

There is nothing wrong with using clamps too, but they are not really necessary if you use the correct fuel line.

VW made 22 million bugs which did not use clamps on the hoses, and they were/are GOOD engineers.

The lack of clamps does not cause fuel fires - engine fires are almost invariably a result of the brass inlet spigot falling out of the top of the carby with the fuel line still attached, and as described above there are various good methods of preventing this happening. The other main cause is the fuel line itself not being replaced after a reasonable time so it cracks under the cotton coveriing, or starts to split at the ends, and sprays fuel.

One problem which does exists now which did not exist a few years ago is the quality of the "genuine" VW fuel hose. It's often very thin walled and rots/cracks in a few months. My local VW supplier now gets fuel hose for early BMWs which is exactly the same as the 5.5mm VW hose of old, and this stuff is much thicker walled, better quality rubber, and lasts like the original VW fuel hose did - several years at least.

Regards

Rob

Rob and Dave's aircooled VW pages

Repairs and Maintenance for the home mechanic

www.vw-resource.com

Rob

Rob and Dave's aircooled VW pages

Repairs and Maintenance for the home mechanic

www.vw-resource.com