Re: Very Basic Off-road Ball-Joint Beam rebuild

Posted: Sat Jun 09, 2012 9:10 pm

After taking 30 lashes with a wet noodle from HRS about not using bluing and a scribing to do my work I moped around here for a day or two and since this string is intended to show a build, point out successes, failures and anything else the comes up so that others don't make them and since I think the instructions try to do too much in one set of instructions (K&L and BJ) which photos and some additional text might clear up some of the: 'what the..." that I decided to go back and blue the whole thing and scratch the puddin out of it with a sharp instrument assuming I can find mine or have to go purchase one that is sharp and to the point.

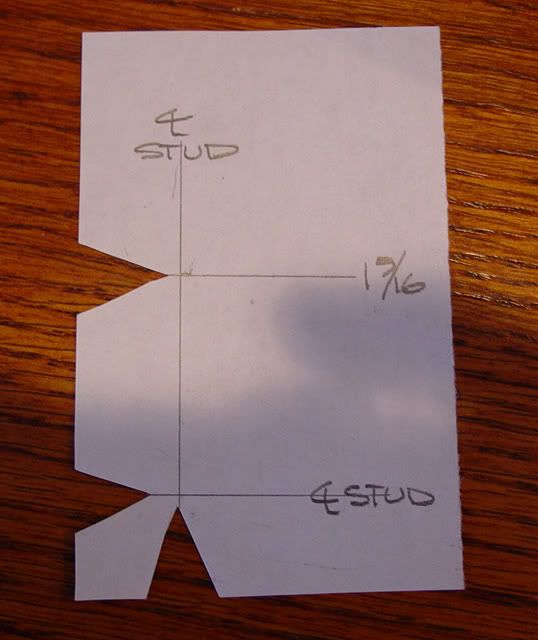

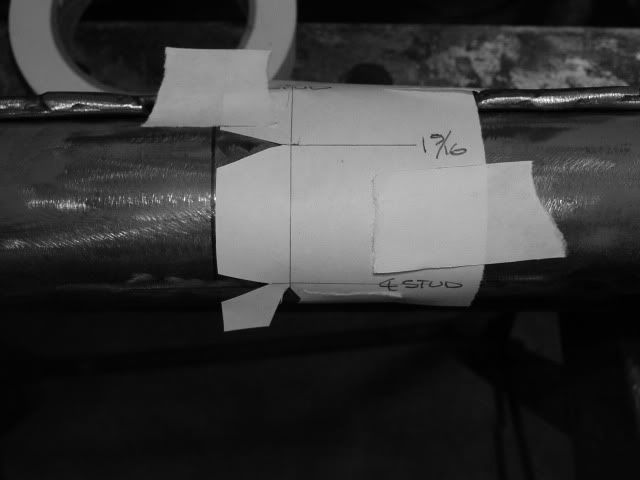

I went out looking for the http://www.officedepot.com/a/products/9 ... und-Ruler/ which is turning out to be quite comical. All of the people I talked to had no clue what I was talking about (not unusual in itself) but when it finally struck them what it was, a (seemed to anyway) light came on and I think they thought it was a good idea. No luck yet on finding one locally but Monday is a day I can hit up some plumbing shops but if I can't find one (I don't like to order on line) so I can always mark a piece of paper with dimension and go from there; whoo-hoo! Paper will wrap around a tube quite nicely thank you!

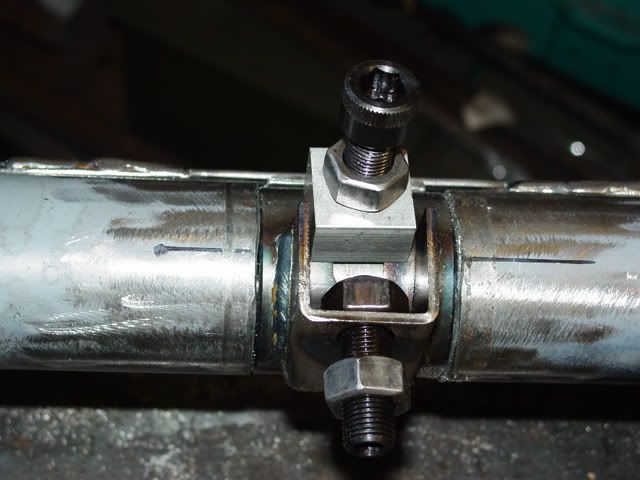

Since I was going to do it correct, I decided to make a welding/alignment jig (Steve talked about it) on this build as I am going to do a K&L beam after this build. For some reason I thought that the tubes slipped into the adjusters but they don’t, it is a butt fit. Well, so much for not trusting my welding ability so I’ll have to fake it and go for the gold myself. Before I go much farther on the jig I will take some pictures so you can see what I have in mind. I had allowed for some welding highs and lows in the jig but since the adjusters are roughly .05 (give or take) smaller in diameter than the beam tubes I have to make a center plate that is .02 thicker. Sometimes it is good to be lucky rather than good which today lucky appearently showed up. I’ll tell you about that tomorrow assuming I get a chance to be in the garage for any length of time (see, just on TV, they lie to you just enough to get your interest then drop you when you come and watch. Hey, I’m getting good at this!).

Lee

I went out looking for the http://www.officedepot.com/a/products/9 ... und-Ruler/ which is turning out to be quite comical. All of the people I talked to had no clue what I was talking about (not unusual in itself) but when it finally struck them what it was, a (seemed to anyway) light came on and I think they thought it was a good idea. No luck yet on finding one locally but Monday is a day I can hit up some plumbing shops but if I can't find one (I don't like to order on line) so I can always mark a piece of paper with dimension and go from there; whoo-hoo! Paper will wrap around a tube quite nicely thank you!

Since I was going to do it correct, I decided to make a welding/alignment jig (Steve talked about it) on this build as I am going to do a K&L beam after this build. For some reason I thought that the tubes slipped into the adjusters but they don’t, it is a butt fit. Well, so much for not trusting my welding ability so I’ll have to fake it and go for the gold myself. Before I go much farther on the jig I will take some pictures so you can see what I have in mind. I had allowed for some welding highs and lows in the jig but since the adjusters are roughly .05 (give or take) smaller in diameter than the beam tubes I have to make a center plate that is .02 thicker. Sometimes it is good to be lucky rather than good which today lucky appearently showed up. I’ll tell you about that tomorrow assuming I get a chance to be in the garage for any length of time (see, just on TV, they lie to you just enough to get your interest then drop you when you come and watch. Hey, I’m getting good at this!).

Lee