On this glass buggy think of it this way: It has fenders and running boards as part of the body: they are in the way of getting close to the inside of the buggy. People want to look at the buggy so they try to step on the running boards to either look in or get in: NO! they are not supported yet The running boards and, much less the fenders, keep you about a "short foot" (I just went out and measured and they are 10" at the cowl and 6 1/2" at the rear fenders (remember that a stock bug does the same thing; it flairs out from the front firewall towards the back then at latching side door post it then bends back to the rear of the pan). Add to that 2" for the structural flange along the body side's upper sill that bend in adding more difficulty and less access to the inside of the body.

The buggy is not on stands right now which lowers the sill height considerably and keeps you from having to chase the buggy rolling around as you work on it. As the buggy sits right now, the lowest part of the sill, where the front of the seat will be is ~32" off the floor. I have a roll around stool who's wheels collapse up when weight is put on the stool that I use to get in and out of the body. If that stool moves when I am getting in the almost doing a split to step in will turn into the splits and "the family jewels" will be spread all over the sill... if you know what I mean. Awkward to say the least.

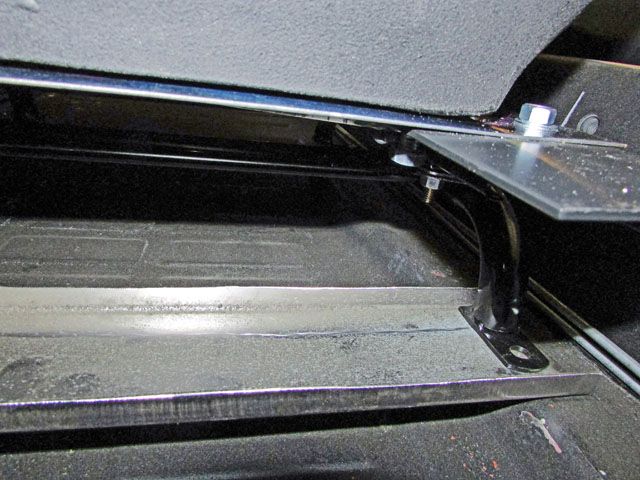

Look at the distance between the shifter and the dash. The dash is very close to the top of the shifter and the dash is just slightly ahead of the shifter. With the one seat sitting roughly where I think it will be the dash is a reasonable distance away from your legs but when the steering wheel gets installed (the seats location and height are in important part of the puzzle as it determines the cage and the front cross bar is where the steering column is supported). I want the seats sitting as low as possible. Just one of the reasons is to keep the cage from getting too high.

To ease the access if getting in and out, the steering wheel will have to be removable but then the steering shaft is going to be a menace especially during getting into the buggy.

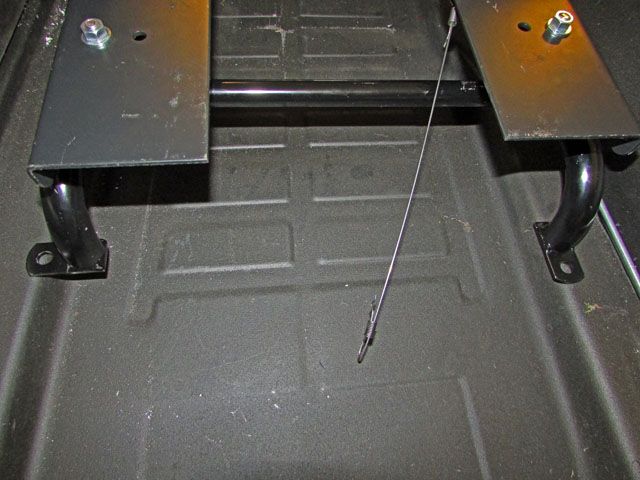

The design of the cage is going to be a big factor in the location of the steering column and access too. Right now my blue buggy has the bars between the front and rear hoops with a bend in the middle to ease access and keep the body away from any trees assuming I get into a "leaner" situation. Mostly they are for ease of access. I also have a third bar in the center which is great for pulling yourself up and out of the seat. It also is good for the GoPro to mount to. The pushing up on the tunnel to get out is going to be a problem, which I have already mentioned, if I use the turning brake setup that RyanB came up with where the cylinders are mounted a distance behind the handle pivots and there are long rods going between the seats. I will have to build a protection for them (no cup holders!).

Notice that there are no doors on the buggy. I have seen two glass buggies with doors (I don't consider the Maxi Taxi as dune buggy in the Manx class) and they are short doors; no room to access and go under the dash in a reclined position. Working under the dash on a glass buggy is not an easy task at best and this body style is even worse especially when the seats are in place. I have to make the mount to the floor strong but their removal quick and easy and that includes the seat mount also. Also notice that the buggy seems to be narrow under the dash. I don't think it is but I think (I haven't measured) the dash is farther to the rear then a bug or glass bodied buggy.

There is no accessibility under the hood. It is a solid piece of the body and sits very low at that. Other than the master cylinders that area is not be available for use unless I add an Aaa-oooga horn. The hood not being able to be opened is fairly common in the Berry Mini-T style of buggy bodies as most glass bodies are able to have their hoods lifted off... assuming one can figure out the locking mechanism. On a glass buggy: to get access to the MC you usually remove the hood and wha-la, there it is. You can also access the MC by going in under the fender but it is tight even if you turn the wheels to the right.

In this case I am not going with spindle mounts but with hubs so the bolt on wheel can be removed for easier access to the MCs. The steering tires I have are 670s which are a large diameter style but not the largest diameter steering tire out there. The large diameter make MC access a bit tighter adding to that the running boards and fenders. It will still be tight filling the MCs but should be easier.

Again, the fuel tank is going to be in the rear under the apron with the engine and Truss/Kaffer bar.

No rear seat although the body came with the lower part of the seat. No room for the passengers and they would sit way too high in the buggy. I just don't think it would be safe whether I was a good or bad driver. I would want them to be within the body lines not with only their legs being inside. The rear cross-piece is the bad guy here. A custom chassis would have made things a bit easier but too late for that.

What I have listed here is just part of what has/had to be considered but it will give you an idea why I did some things one way and not other ways. Did I make mistakes... good lord yes but sometimes that is the way you have to learn... sometimes. I do take advice although it may not seem like it but I do consider any and all advice. If I have already thought about some advice given to me and decided not to go that way... I will still rethink it and don't reject it out of context. I do appreciate all input... for sure!

Would I attach this style of buggy again... ask me again when I am done.

Lee