I did get started working on fixing the body for the black buggy to fit onto the body lift today; the more I got into it the worse things became. Today was a windless day and the heavy dew did not burn off until later this am. I had to wait some for the moisture to lift as it was pretty slippery on the concrete. If it didn’t frost this am, it was very close to it.

I started out at about 9:00 AM, rolling the pan and the body stand out then cleaning and rearranging the garage; then I modified the body carrying stand that I built years ago by adding a new cross-piece to allow the body and the body lift to slide forward to clear the front of the stand’s frame; this was done for better access to the Nepoleon's hat and the side mount flange areas. After modifying the stand, I finagled the body lift off the rotisserie and on to the wood stand and under the body.

Using an air powered cut-off tool 3-inch, an air saw, an angle grinder with a green (40 grit I think) sanding disc on it, a mask, mechanic’s style gloves and safety glasses (which I discarded as they immediately sucked and collected all the fiberglass dust to them) and an air blow off tool I got into whacking up the forward lower surfaces of the body;

e.g., I removed the Nepoleon’s hat mounting flange and forward side mounting flanges, then cut up on the front fire wall about an inch to lower the front of the body down onto the body lift and generally making a mess in the front of the house. Once I got things somewhat lowered down and roughly fitting I stood back and: Oh $&%*t, the rear body mount flanges (which I already knew were pretty bad to start with) were worse than expected and holding the passenger side up off the lift.

The angles of the flanges did not match the frame (I was aware of the warping of the flanges but the angle difference which I though was small was larger than anticipated. It wasn’t until I had slid the body towards the rear that this became obvious. Time to give up and do some honey-do’s; like repairing broken concrete which was much more exciting.

After working outside from about 9:00 am, I finally had enough at about 1:30 pm and called my friend who was going to help me glass the body back to fit the lift and called tomorrow’s glassing session off. Tomorrow I will cut the rear cross mount flanges, which were already slated to be modified, just not as much as they are going to have to be and make new spherical radius to get the body to sit down on the body lift.

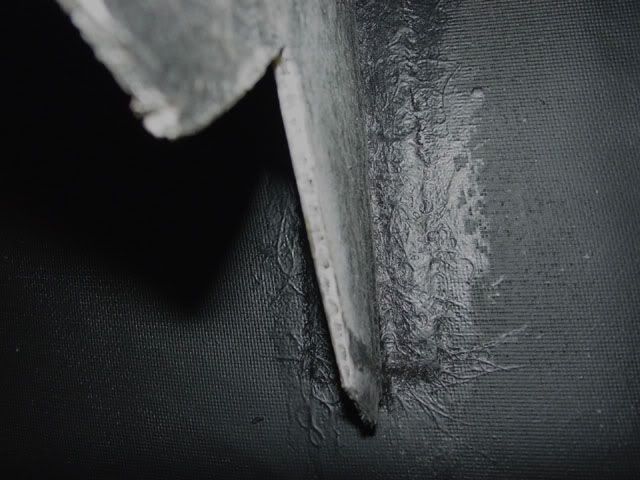

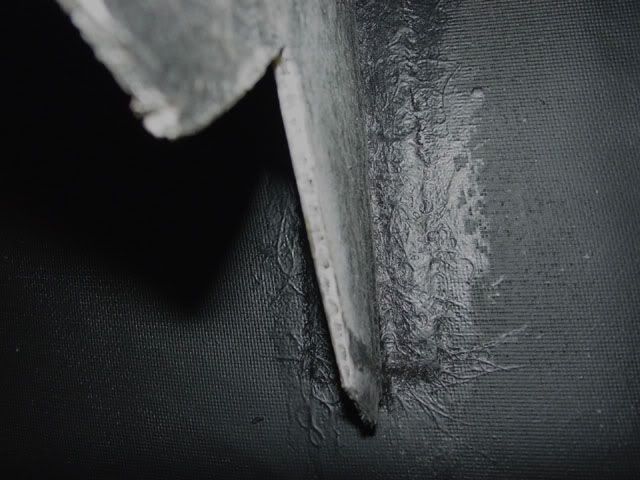

The front fire wall is different type of fiberglass than I have seen in the aftermarket automotive industry as it is hollow and looks almost like a honey comb material. We used glass impregnated (e.g., pre-preg) paper honey comb in aerospace but it required an autoclave to heat the resin up so that it would flow. I don’t think this is paper honey comb… but it sure looks a lot like it. This was taken at the rear inner fender well and shows a little what the material looks like. My camera was too close and the flash washed out most of the detail but maybe you can get an idea of what it is.

This is where I am right now.Lee