IRS Chassis flex?

-

fastbacker

- Posts: 43

- Joined: Tue Aug 01, 2006 9:35 am

IRS Chassis flex?

I'm wondering where and how much the type I irs chassis flexes under hard cornering with, say wide tires and a stiff suspension. My guess would be the rear torsion tube in relation to the pan/body and also the front beam in relation to the pan/body. Not sure how much though.

The reason I'm trying to figure this out is to possibly weld in some reinforcement bars to stiffen up my "in the works" 69 street bug. The car's at my friends fab shop undergoing a major transformation. The front end is done and we're getting ready to move onto the rear suspension. Then the engine and tranny. The parts list (all of which I have) are:

-3" narrowed beam

-CB dropped spindles modified by Lanner to accept 944 turbo calipers

-944 turbo narrow arms, t-bars spring plates and brakes

-901 5speed w/ lsd converted using all of bug@5speed parts

-914 2.4L converted with DTM - 195hp

-964 wheels (6&8X16)

The reason I'm trying to figure this out is to possibly weld in some reinforcement bars to stiffen up my "in the works" 69 street bug. The car's at my friends fab shop undergoing a major transformation. The front end is done and we're getting ready to move onto the rear suspension. Then the engine and tranny. The parts list (all of which I have) are:

-3" narrowed beam

-CB dropped spindles modified by Lanner to accept 944 turbo calipers

-944 turbo narrow arms, t-bars spring plates and brakes

-901 5speed w/ lsd converted using all of bug@5speed parts

-914 2.4L converted with DTM - 195hp

-964 wheels (6&8X16)

-

helowrench

- Posts: 1925

- Joined: Wed Aug 11, 2004 6:20 am

I have been keeping my eyes open for a list of the stiffening sheetmetal used for the 'vert chassis. these parts would go a long way to achieving the goal you seek. If you find any info please share with us.

Also look into a "kafer brace" as it ties in the engine mount horns, and the shock mounts to allow them to stiffen up each other. (this can be done with generic rod ends from Grainger/Tractor Supply with hand fabbing, I would also make an attach to the boby sheetmetal over the trans or so)

Rob

Also look into a "kafer brace" as it ties in the engine mount horns, and the shock mounts to allow them to stiffen up each other. (this can be done with generic rod ends from Grainger/Tractor Supply with hand fabbing, I would also make an attach to the boby sheetmetal over the trans or so)

Rob

-

kdf

- Posts: 110

- Joined: Fri Jun 03, 2005 5:37 am

The rear suspension mounts are important, but there isn't much you can do to bring more camber stiffness. You can of course change to urethane bushings (or in extreme case metallic bushings). I would prioritize stiffness in this order: Camber and toe stiffness, damper mount stiffness and as last torsional stiffness.

With the power you'll have, you will want to stiffen the engine mounts.

I know you mentioned that you've already done the front, but stiffening the front beam is important so I wanted to mention it. You can move the beam just by standing on it in stock form.

Changing the rubber to urethane between the steering shaft and the steering box also makes a small difference.

The devil is in the detail. The stock bug isn't made stiff because it wasn't meant to be a sporty car.

With the power you'll have, you will want to stiffen the engine mounts.

I know you mentioned that you've already done the front, but stiffening the front beam is important so I wanted to mention it. You can move the beam just by standing on it in stock form.

Changing the rubber to urethane between the steering shaft and the steering box also makes a small difference.

The devil is in the detail. The stock bug isn't made stiff because it wasn't meant to be a sporty car.

-

fastbacker

- Posts: 43

- Joined: Tue Aug 01, 2006 9:35 am

I'm sure it's not easy to explain but I'll ask anyways, how?kdf wrote:I would prioritize stiffness in this order: Camber and toe stiffness, damper mount stiffness and as last torsional stiffness.

I know you mentioned that you've already done the front, but stiffening the front beam is important so I wanted to mention it.

Thanks for the informed input!

-

volkdent

- Posts: 475

- Joined: Sun Jul 08, 2001 12:01 am

These may be helpful tied into the beam stiffeners...

http://www.eyeball-engineering.net/Floo ... fners.html

Jason

http://www.eyeball-engineering.net/Floo ... fners.html

Jason

1960 "Bad Dub" http://youtu.be/VEUPxTw11hk

Drag http://youtu.be/NNcPQDiNPQE

Dyno http://youtu.be/51_JRESS0Tg

1957 "Ragster" http://germanlook.net/forums/showthread.php?t=11514

Drag http://youtu.be/NNcPQDiNPQE

Dyno http://youtu.be/51_JRESS0Tg

1957 "Ragster" http://germanlook.net/forums/showthread.php?t=11514

-

helowrench

- Posts: 1925

- Joined: Wed Aug 11, 2004 6:20 am

- 681tonburb

- Posts: 62

- Joined: Wed Apr 30, 2008 12:46 am

- 681tonburb

- Posts: 62

- Joined: Wed Apr 30, 2008 12:46 am

-

fastbacker

- Posts: 43

- Joined: Tue Aug 01, 2006 9:35 am

-

helowrench

- Posts: 1925

- Joined: Wed Aug 11, 2004 6:20 am

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Chassis Flex

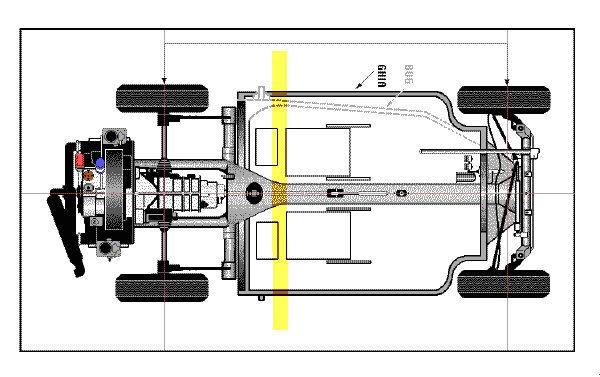

Yes, the Type 1 chassis flexes, and it's worst place is right where you see the yellow highlight.

The only genuine fix I know of for it is a rollbar system that ties the rear shock supports to the main hoop and then to the chassis near or beside the seats.

Our current bar connects to the body in the rear cargo area, which of course helps the chassis somewhat, and the chassis floor just ahead and beside the seats. We tie the front contacts together crossways under the car with a heafy piece of aluminum U-channel mountd open side down.

It makes a nice front jack support bar.

FJC

-

fastbacker

- Posts: 43

- Joined: Tue Aug 01, 2006 9:35 am

- 681tonburb

- Posts: 62

- Joined: Wed Apr 30, 2008 12:46 am

I’m sure you could just weld the tunnel over the frame so that the vin plate is there. We don’t have to worry about that here no one is going to check it.

I thought of using the 944 torsion tub and bolting it on but the 944 track with is to wide. The 944 is 68 and the bug is 60.

I didn’t build the mane part of the frame I had it built so that it could be done in a jig I was worried if I did it my self I wouldn’t get it straight. I was delivered to me like you see it in the pic and then I added the rear suspension and floors. Originally I was going to add a mustang front suspension on it but I ended up needing to save some cash so I decided to use a VW front end now.

I thought of using the 944 torsion tub and bolting it on but the 944 track with is to wide. The 944 is 68 and the bug is 60.

I didn’t build the mane part of the frame I had it built so that it could be done in a jig I was worried if I did it my self I wouldn’t get it straight. I was delivered to me like you see it in the pic and then I added the rear suspension and floors. Originally I was going to add a mustang front suspension on it but I ended up needing to save some cash so I decided to use a VW front end now.

-

helowrench

- Posts: 1925

- Joined: Wed Aug 11, 2004 6:20 am