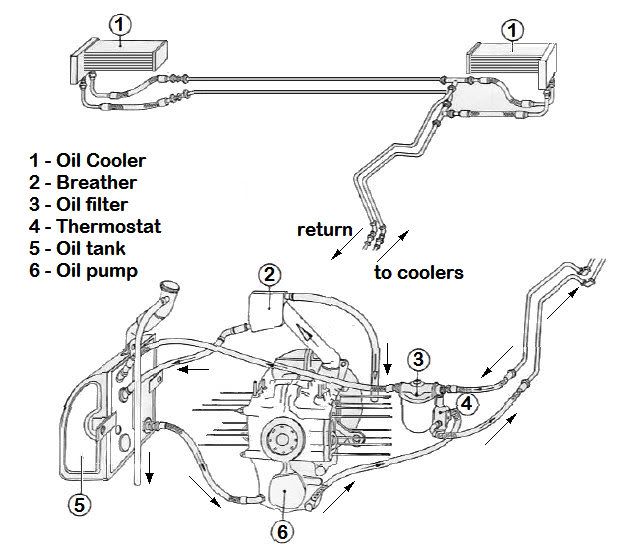

Our Type 1 road racing endurance engines are dry-sump, with CB Performance 2-stage pumps. The CB pump is made by Schadek, with 26mm scavenge (inner stack) case to tank and 21mm pressure stage, (outer stack) tank to bearings.

That means we have 21mm pump gears pressuring the engine, and 26mm gears sucking oil from the case back to the tank. Each stage has its own oil passages.

Of course, comparing a one-stage pump to a two-stage is not quite apples to apples because a single stage has to expend all its flow through one set of passages to both suction and pressure.

As the VW community has so painfully learned, bigger oil pumps alone are not the fix for oil pressure problems. The condition where a bigger pump and/or thicker oil can keep the oil pressure relief valve depressed and force hot oil to the bearings while providing low flow to the cooler is a race engine killer.

Like many (most?) VW engines racers, once we reach high oil temperatures (generally over 220° F), our low RPM oil pressure goes away. For us, this is on a 96-plate cooler with a 9-inch electric fan, 10w30 and 10w40 oil. Three gallons of oil ... all of which is usually up against 90° F southwest US summer days and a minimum of 7-hour enduros per day.

And, we're about to add Type 4 power to our armory. The Type 4 uses the exact same CB pump. Which means a remote oil cooler, filter, everything.

So, when I found out about Head Flow Masters Racing Oil Check Valves, it gave me hope for the better.

Audirac Racing Oil Check Valve kit

http://www.headflowmasters.com/vw-oil-p ... -body.html

The trouble is, no one answers the phone or e-mail there. Not for weeks.

Bernie Bergmann

http://www.bergmannvw.net/

Next, I tried Bernie Bergmann who has a similar steel ball check valve kit he used to sell, but to my surprise, Bernie warned me off them. "You need a new case to use the kit," he said. "If you have a worn bore and that sleeve comes loose, it'll destroy your engine. I wouldn't do it. It doesn't make that much oil pressure difference anyway."

So, I have to revert to Plan B. Here they are:

CSP Full Flow Adapter

http://tinyurl.com/llbezxp

EMPI Full Flow Adapter

http://tinyurl.com/krrugqs

Neither of these fit Type 4's, but what I learn from the Type 1 application should apply, especially with an external oil thermostat and perhaps an external pressure relief device such as these full-race devices at Jegs.Com

http://tinyurl.com/mtmf3wj

My idea is to use the full flow adapter design at least as far as it replacing the relief spring and piston, so 100% of the oil goes to the external filter and cooler all the time. CSP shows little respect for the factory piston and spring design, calling it a cheap thermostat. Read their ad.

The Porsche Type 547 dry sump racing engine used an external thermostat.

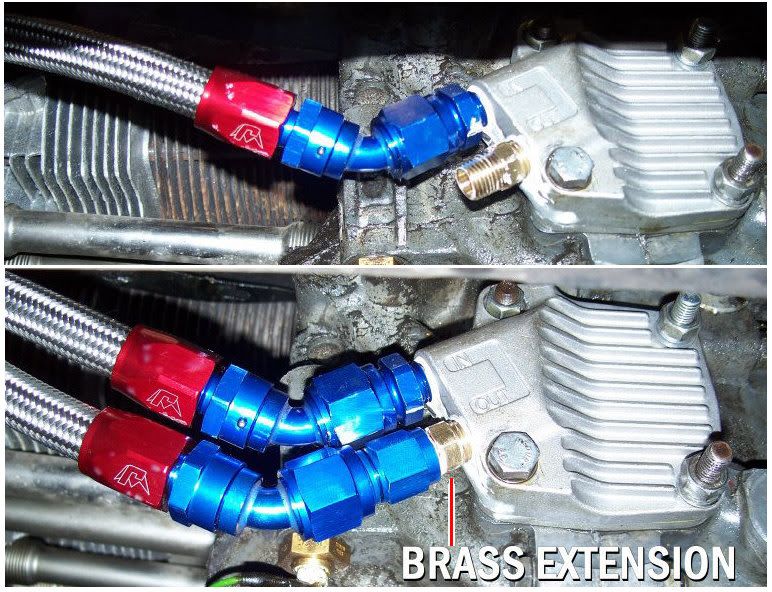

With an external thermostat to aid quick warmups before the oil goes to the cooler. Here's the device I've picked. It has 1/2" not 3/8" fittings.

Disabling the stock oil pressure relief valve at the pulley end of the engine does not affect the oil pressure control valve near the flywheel. It will continue to dump overpressure back into the case, which is it's job.

http://tinyurl.com/ot38uxg

This all leaves the filter at risk, of course. Here I trust in FRAM HP-1, for it's can strength. HP-1's and I have been through a lot together, from my first VW IMSA road racer Superbug in 1975 and '76, and they have never let me down.

The goal here is lower oil temps and better idle pressure.

I'll let you know how it works.

FJC